build cnc machines Explore our versatile CNC solutions tailored to your needs. Choose from complete Plug and Play CNC Control Systems or let us expertly wire your electronics into a feature-rich cabinet. Perfect fit for any CNC requirement. Learn More & See Prices Since 1938 G&H has been a supplier of structural enclosures, sheet metal fabrication, and welding services. We are a custom sheet metal job shop specializing in prototypes, short-run .

0 · make your own cnc machine

1 · homemade cnc machine plans

2 · do it yourself cnc machine

3 · building your own cnc machine

4 · build your own cnc mill

5 · build your own cnc kit

6 · build your own cnc

7 · build it yourself cnc router

Filler Metal: Since TIG welding uses non-consumable electrode, we’re going to need filler metals to cover up the gap. Required materials: Now let’s take a deep look into the required materials: 4 steel angle table legs; Tabletop sheet metals; One 4″ round tubing; 4 casters with brakes; Galvanized or non-zinc nuts

make your own cnc machine

Explore our versatile CNC solutions tailored to your needs. Choose from complete Plug and Play CNC Control Systems or let us expertly wire your electronics into a feature-rich cabinet. Perfect fit for any CNC requirement. Learn More & See PricesBuild your CNC. CNC ROUTERS/LASERS; Products; Customer Service . others on .

fine metal mesh fabric

Laser Components. Below you will find all of the laser components you will need to .Enhance the safety and efficiency of your CNC machines and automation systems .The CNC router plans come in a 24"x36" 40 to 50 page document set. The plans .

NEMA 17 CNC Motor (84 oz-in 5mm shaft) 1.68 Amps Elevate your CNC, laser, or .This is a ball screw and ball nut just shy of 1 inch major diameter (24.86mm). The .

Livestreams Every Weekday at 1:00 pm Eastern Join me and likeminded others .This 1/4" machine hex nut can mate with any of our 1/4" screws. The UNC . A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

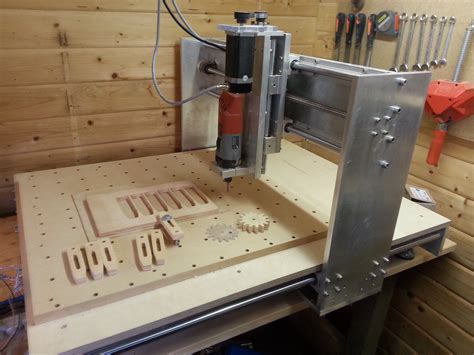

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal . Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled. It .

The latest cnc machines are controlled via gcode and grbl, repetier, or Marlin based controllers. Using mach 4 is a bit like using Windows to set up a file server. How to Build a CNC Machine Structure? Building a solid structure is essential for your CNC machine. It not only holds all the components together but also ensures accuracy and precision during operations. Here’s a step-by .How to Make a Three Axis CNC Machine (Cheaply and Easily): The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. While it would have been nice to purchase an off the shelf unit the issue of price as .Explore our versatile CNC solutions tailored to your needs. Choose from complete Plug and Play CNC Control Systems or let us expertly wire your electronics into a feature-rich cabinet. Perfect fit for any CNC requirement. Learn More & See Prices

A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin.This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled. It also includes instructions of how all the necessary open-source softwares are installed. The latest cnc machines are controlled via gcode and grbl, repetier, or Marlin based controllers. Using mach 4 is a bit like using Windows to set up a file server.

How to Build a CNC Machine Structure? Building a solid structure is essential for your CNC machine. It not only holds all the components together but also ensures accuracy and precision during operations. Here’s a step-by-step guide: 1. Choosing the Right Material. Aluminum Profiles: Popular for DIY CNC frames because of their modularity .How to Make a Three Axis CNC Machine (Cheaply and Easily): The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. While it would have been nice to purchase an off the shelf unit the issue of price as well as size proved prohibitive.Explore our versatile CNC solutions tailored to your needs. Choose from complete Plug and Play CNC Control Systems or let us expertly wire your electronics into a feature-rich cabinet. Perfect fit for any CNC requirement. Learn More & See Prices A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

I decided to put my engineering background to the test, and build my own CNC machine with the ability to be upgraded and use the least amount of tools possible. This Instructable includes what I've designed and how to follow these steps to create your own machine.This Instructable will show you how I built my CNC milling machine. I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine.

Learning how to build a CNC machine from scratch is easier than you might think. We have broken down the DIY process into a series of easy-to-follow steps for beginners. From buying parts to installing software, our DIY guide will walk you through how to easily make your own CNC machine.Learn how to build your very own CNC machine with this ultimate guide for makers! This step-by-step tutorial covers everything you need to know, from choosin.

This guide goes through all the steps to build your own CNC machine from scratch. It includes a complete bill of materials (BOM), STL/OBJ-files for all the 3d-printed parts and detailed instructions of how everything is assembled. It also includes instructions of how all the necessary open-source softwares are installed. The latest cnc machines are controlled via gcode and grbl, repetier, or Marlin based controllers. Using mach 4 is a bit like using Windows to set up a file server. How to Build a CNC Machine Structure? Building a solid structure is essential for your CNC machine. It not only holds all the components together but also ensures accuracy and precision during operations. Here’s a step-by-step guide: 1. Choosing the Right Material. Aluminum Profiles: Popular for DIY CNC frames because of their modularity .

homemade cnc machine plans

do it yourself cnc machine

find house lan junction box

building your own cnc machine

Waterproof Junction Box, IP68 Outdoor Junction Box, 2 PCS 3 Way Plug Line External Junction Box, M25 Plastic Electrical Junction Box Suitable for Tunnel Lights, Garden Lights, Landscape Lights

build cnc machines|building your own cnc machine