5 what is the sheet metal working process Sheet metal fabrication is a comprehensive working process for sheet metals (usually thinkness less than 10mm), including shearing, blanking, bending, welding, riveting, mold forming and surface treatment.

Comparing the electrical enclosures rating standards of NEMA and UL. Here’s a side-by-side look at the environmental ratings between the National Electrical Manufacturers Association and Underwriters Laboratories, Inc. for .

0 · various sheet metal processes

1 · types of sheet metal process

2 · sheet metal working process pdf

3 · sheet metal processes pdf

4 · sheet metal process in manufacturing

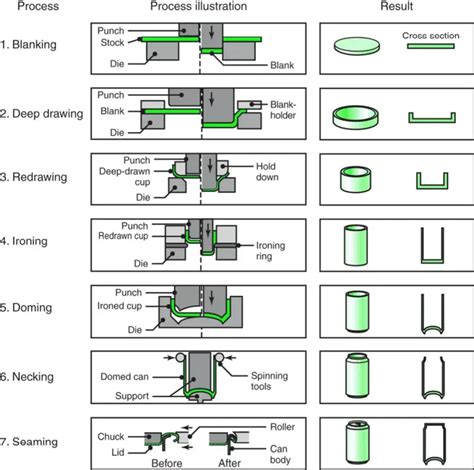

5 · sheet metal operations with diagrams

6 · sheet metal forming process pdf

7 · sheet metal fabrication pdf

Did you know AtticFoil™ replaces Tyvek® as a house wrap behind siding? Using a radiant barrier as a house wrap is rapidly gaining popularity and yes, you can add AtticFoil™ to the exterior of your home/building to maximize comfort by reflecting radiant heat on all sides.

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly .

In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing. You can produce quality fabricated parts from your shop by understanding the basics.

Stamping is a fundamental sheet metal forming process widely employed in manufacturing industries such as automotive and appliances. This process involves shaping metal sheets into desired forms and configurations using .

The process involves the sheet metal being placed over a die, then pressed with a punch into an open cavity, causing the material to undergo plastic deformation. The process allows for precisely made complex shapes . Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, . Sheet metal fabrication is a comprehensive working process for sheet metals (usually thinkness less than 10mm), including shearing, blanking, bending, welding, riveting, mold forming and surface treatment.Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious .

Sheet metal fabrication is a process of working with metal, used in various industries, ranging from construction and automotive to warehouse and electronics. It involves transforming flat sheets of metal into functional .Below, we’ll explain the most common metal manufacturing processes: The first step in the sheet metal fabrication process is cutting, which is where the fabricators will slice the raw materials .

What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms.Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing. You can produce quality fabricated parts from your shop by understanding the basics.

Stamping is a fundamental sheet metal forming process widely employed in manufacturing industries such as automotive and appliances. This process involves shaping metal sheets into desired forms and configurations using specialized dies and punches. The process involves the sheet metal being placed over a die, then pressed with a punch into an open cavity, causing the material to undergo plastic deformation. The process allows for precisely made complex shapes and designs with deeper features. Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, there are two categories of . Sheet metal fabrication is a comprehensive working process for sheet metals (usually thinkness less than 10mm), including shearing, blanking, bending, welding, riveting, mold forming and surface treatment.

gfci in a metal box

Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious intersection of creativity, precision, and technology.Sheet metal fabrication is a process of working with metal, used in various industries, ranging from construction and automotive to warehouse and electronics. It involves transforming flat sheets of metal into functional components and structures through cutting, .

Below, we’ll explain the most common metal manufacturing processes: The first step in the sheet metal fabrication process is cutting, which is where the fabricators will slice the raw materials into the parts needed to complete a project. Getting precise cuts is critical.

What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms.

generator distribution box

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing. You can produce quality fabricated parts from your shop by understanding the basics.Stamping is a fundamental sheet metal forming process widely employed in manufacturing industries such as automotive and appliances. This process involves shaping metal sheets into desired forms and configurations using specialized dies and punches. The process involves the sheet metal being placed over a die, then pressed with a punch into an open cavity, causing the material to undergo plastic deformation. The process allows for precisely made complex shapes and designs with deeper features.

Sheet metal processing is a vast concept, covering several machining operations done to metal sheets. Since the topic is too broad, most people think the overall process only boils down to a single function. However, there are two categories of . Sheet metal fabrication is a comprehensive working process for sheet metals (usually thinkness less than 10mm), including shearing, blanking, bending, welding, riveting, mold forming and surface treatment.Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious intersection of creativity, precision, and technology.Sheet metal fabrication is a process of working with metal, used in various industries, ranging from construction and automotive to warehouse and electronics. It involves transforming flat sheets of metal into functional components and structures through cutting, .

various sheet metal processes

types of sheet metal process

generator housing metal

UL 50 and UL 50E, the two essential UL standards on Enclosures for Electrical Equipment, have just been updated. Here’s a quick review of each of these two important publications and their changes: UL 50, 13th Edition, Enclosures for Electrical Equipment, Non-Environmental Considerations.

5 what is the sheet metal working process|sheet metal process in manufacturing