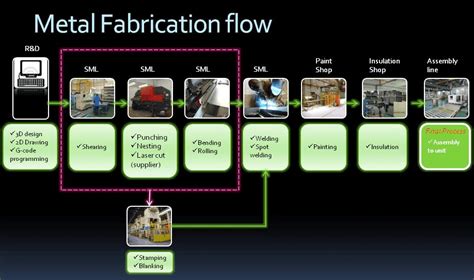

sheet metal fabrication manufacturing process The sheet metal fabrication process can be broadly categorized into two main approaches: Non-die processing: This method utilizes advanced CNC (Computer Numerical Control) equipment such as punching machines, .

Our furniture upholstery is durable without compromising style and sophistication. Our selection of upholstery fabric is wide-ranging, so there are plenty of options for you to choose from. Whether you are looking for online upholstery fabric or want to .

0 · types of sheet metal fabrication

1 · sheet metal manufacturing process types

2 · sheet metal layout drawings

3 · sheet metal bending chart

4 · how to fabricate sheet metal

5 · disadvantages of sheet metal

6 · design guidelines for sheet metal

7 · basics of sheet metal fabrication

Using the Machine Tending Copilot algorithm, the robot finds the optimal .

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In . Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly . Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to .The precision sheet metal fabrication process involves producing precise sheet metal components for vehicles. The process begins with design, followed by cutting, forming, joining, finishing, quality control, and packing.

Sheet metal fabrication is a versatile manufacturing process with an extensive list of techniques and usable metals. Getting familiar with the technology, how it works, and its applications will help you decide if it is the . The sheet metal fabrication process can be broadly categorized into two main approaches: Non-die processing: This method utilizes advanced CNC (Computer Numerical Control) equipment such as punching machines, . Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high strength-to-weight ratio, durability, and versatility. This guide will . 1. What is sheet metal fabrication? Sheet metal fabrication is a valuable prototyping and production method for making robust functional parts like panels, brackets, and enclosures.

What Is Precision Sheet Metal Fabrication? Precision sheet metal fabrication is a manufacturing process that shapes raw metal sheets into detailed components. This process involves multiple techniques, such as punching, forming, cutting, and welding. Computer Numerical Control (CNC) plays a vital role in precision sheet metal fabrication.Unlock the full potential of your manufacturing processes with our comprehensive guide to sheet metal fabrication. Dive into the details of transforming flat metal sheets into high-quality, functional parts and products. From cutting-edge . Our skilled engineering team is equipped to manage an entire sheet metal fabrication process, from laser cutting to assembly to final delivery. We believe IMS is fabricating the only way a company can if it wants to be .

Fabrication of sheet metal is a manufacturing process that involves shaping and manipulating thin sheets of metal into desired parts and components. It typically includes cutting, bending, forming, and assembling metal sheets to create various products such as enclosures, brackets, panels, and many more.Sheet metal is highly compatible with the process, allowing custom sheet metal fabricators to create diverse products with optimal design versatility and reliable quality. The ideal fabrication partner will offer the manufacturing and secondary finishing services you need with the precision necessary to ensure tight-tolerance, high-performance . Sheet metal fabrication is a manufacturing process that utilizes sheets of metal to create a wide range of different parts and products. However, the term “sheet metal fabrication” specifically refers to the numerous manufacturing techniques used with sheet metals, including laser cutting, bending, welding, and forming.

The fabrication process of sheet metal enclosures involves several key steps, from initial concept to the final product. Understanding each phase can help ensure that the finished enclosure meets all technical specifications and quality standards. . Additionally, minimizing seams can simplify the manufacturing process and reduce costs, while . Common Applications for Precision Fabrication. Precision sheet metal fabrication is a versatile manufacturing process used to create a wide range of components and products with high accuracy and consistency. Some common applications of .Sheet metal fabrication is the process of forming a metal sheet into a desired shape. This is a popular manufacturing process that uses metal sheets for creation of a product. The process is widely used in the metal manufacturing industry. There are a few steps involved in converting a metal sheet into the product. TheseThese qualities make it ideal for high volume manufacturing across many industries. Sheet Metal Materials . Sheet metal fabrication utilizes a variety of metals, each with properties that make them suitable for different applications. . Sheet metal fabrication is the process of shaping thin sheets of metal into useful structures and products .

types of sheet metal fabrication

Sheet metal fabrication is a subtractive manufacturing process that forms parts from thin metal sheets. Engineers often choose sheet metal parts for their high strength-to-weight ratio, durability, and versatility. . Cutting is a fundamental process in sheet metal fabrication. Different cutting methods are used based on the complexity of the .Sheet Metal Fabrication Experts We Make The Best. . Every member of our team believes that the manufacturing process should be fast and simple for all our customers. We deliver on this mission by methodically applying knowledge, speed, quality, and flexibility to every project, for every customer. . We manufacture a wide range of quality . Tools used in the sheet metal manufacturing process. Metal engineering as a whole is an immensely complicated process that requires a lot of precision and experience, as well as a lot of specialized machinery and tools. Here are some of the more commonly used tools in the metal manufacturing process: Laser cutting machinery; CNC machinery Sheet metal fabrication is a dynamic process that involves various shearing processes depending on industry requirements. It involves piercing, punching or blanking during the manufacturing process, depending on the end product. Each fabrication process involves different processing and different tool and dies.

Sheet Metal is the service name under which several manufacturing processes are used to make typically thin-walled metal parts. The process begins by cutting flat stock sheet metal which can then be punched, formed, or stamped to .

Welcome to the definitive guide on sheet metal processing, an essential pillar in a multitude of global industries. From our daily commute vehicles to our indispensable household appliances, countless products we interact with .

Indicating tolerances in sheet metal fabrication drawings revolve around clear communication, understanding the manufacturing process, adhering to international standards, and providing comprehensive details in the . Introduction. Sheet metal manufacturing is a fundamental part of modern industry, transforming raw metal into essential components for a wide range of products, from consumer electronics to heavy machinery. This precision-driven process transforms flat metal sheets into intricate components. Over the decades, sheet metal manufacturing has evolved from manual .

– Press Forming: This process involves using a press to force sheet metal into a mold, creating intricate shapes and bends. It is ideal for small-batch production and allows for greater precision. – Shearing and Cutting: Shearing and cutting operations are used to trim sheet metal to size and make specific incisions. Sheet metal fabrication is a process widely used in modern manufacturing due to its versatility, durability, and cost-effectiveness. It involves shaping and assembling sheet metals into various structures and components for the automotive, construction, aerospace, and consumer goods industries such as creating roofing and gutters.

How does EVS Metal use lean processes in their precision sheet metal fabrication facilities? As a lean metal fabrication and manufacturing shop, . By turning classical lean on its head and focusing on process over product — the exact opposite of the traditional TPS philosophy that inspired lean in the first place. Utilizing lean in this .

FAQs about Industry 4.0 and Smart Manufacturing in Sheet Metal Fabrication How does Industry 4.0 impact sheet metal fabrication? Industry 4.0 revolutionizes sheet metal fabrication by integrating advanced technologies such as smart machines, IoT connectivity, data analytics, and additive manufacturing.

In this sense, sheet metal fabrication can be considered a subtractive manufacturing process (like CNC machining), because usable parts can be made by simply removing sections of material. Manufacturers can cut sheet metal using a variety of different pieces of machinery, some of which are unique to sheet metal fabrication. As the name suggests, the sheet metal fabrication process uses sheet metals to design and develop the products. The guide below comprises detailed information on the process of sheet metal fabrication. . When manufacturing components using sheet metal, it is suggested to avoid flat hems. Having tear-dropped or open hems is preferable as they . Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. This transformation is achieved through a series of techniques such as cutting, punching, folding, bending, stamping, welding, and finishing. . Sheet Metal Fabrication vs Other Metal Manufacturing .

Sheet metal fabrication is the process of transforming flat sheets of metal into finished products or components. This is achieved through various steps that involve cutting, bending, and assembling the metal, allowing it to be shaped and formed as required. . Punching and forming are metal manufacturing process in sheet metal fabrication . There are many different choices to make when using sheet metal to fabricate a product. Decisions have to be made at the design stage, choices such as material selection, material thickness or what kind of finish is required.As part of the design process, it’s important to consider which production technologies might be used when manufacturing the part, and .

lame metallic spandex fabric buy in bulk

sheet metal manufacturing process types

When you're down to one card, don't forget to shout 'UNO!' This fun family card game is perfect for adults, teens and kids 7 years old and up. UNO Tin comes with 112 cards and instructions in a sturdy tin that's great for storage and travel. Colorblind accessible!

sheet metal fabrication manufacturing process|basics of sheet metal fabrication