cnc can do what milling machine basics Dive into the introduction to CNC milling with this beginner's guide. Explore the basics, CNC milling processes, and insights to kickstart your CNC journey. Buy sheet metal parts in bulk online from 56 verified wholesale sheet metal parts suppliers, manufacturers (OEM, ODM & OBM), distributors, and factory lists on Global Sources.

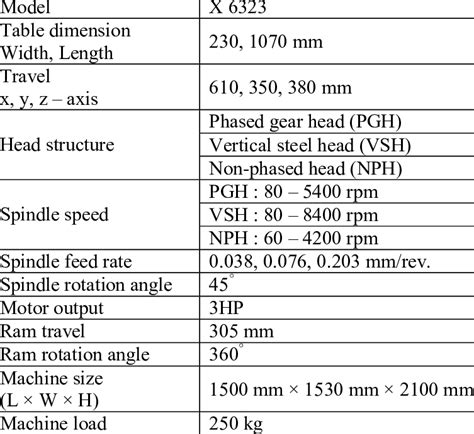

0 · specifications of cnc milling machine

1 · milling process step by

2 · introduction to cnc milling machine

3 · cnc milling tutorial

4 · cnc milling explained

5 · cnc milling diagram

6 · cnc horizontal milling for dummies

7 · basics of the cnc mill

Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. We offer 3D visualized Design for Manufacturability (DFM) feedback to help you manage project costs and receive actionable design insights.

Dive into the introduction to CNC milling with this beginner's guide. Explore the basics, CNC milling processes, and insights to kickstart your CNC journey.

In this guide, we’re going to demystify CNC milling and break it down into bite-sized, beginner-friendly chunks. We’ll cover everything from the basics of how these machines work to the . Milling is a manufacturing method using a rotating cylindrical cutting tool to remove materials from the workpiece and create a wide . CNC machines can mill any material—silicone plastics, wood, stainless steel and nonferrous metals—and are able to produce a wide range of components of varying complexity with consistent, high-quality results. From .

CNC milling machines manufacture medical devices, implants, and prosthetics in the medical field. These machines can produce intricate shapes and precise dimensions required for medical applications. CNC milling technology has .

Computer numerical control (CNC) milling is a process in which automation and milling tools work together, removing material from a workpiece and producing a high-quality finished part or product. It is called a subtractive . CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter . CNC milling, an abbreviation for Computer Numerical Control milling, is a transformative manufacturing process governed by computer software to direct machinery movement. Unlike additive processes such as 3D printing, .

What is CNC milling and how does this subtractive manufacturing process work? This article explores how CNC milling machines work, what kinds of parts you can provide with milling and the best design practices for getting the most out of . Dive into the introduction to CNC milling with this beginner's guide. Explore the basics, CNC milling processes, and insights to kickstart your CNC journey.

CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products.

In this guide, we’re going to demystify CNC milling and break it down into bite-sized, beginner-friendly chunks. We’ll cover everything from the basics of how these machines work to the essential techniques you’ll need to get started. Milling is a manufacturing method using a rotating cylindrical cutting tool to remove materials from the workpiece and create a wide collection of CNC milled parts with different shapes, slots, holes, and dimensions, this is what is a CNC milling machine used for. CNC machines can mill any material—silicone plastics, wood, stainless steel and nonferrous metals—and are able to produce a wide range of components of varying complexity with consistent, high-quality results. From jewelry, to aircraft parts, to medical implants, many of the products in our modern life come to us through CNC machining.CNC milling machines manufacture medical devices, implants, and prosthetics in the medical field. These machines can produce intricate shapes and precise dimensions required for medical applications. CNC milling technology has revolutionized the healthcare industry, from dental implants to surgical instruments.

Computer numerical control (CNC) milling is a process in which automation and milling tools work together, removing material from a workpiece and producing a high-quality finished part or product. It is called a subtractive process, as opposed to the 3D printing additive operations that have become popular over the last decade.

specifications of cnc milling machine

CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter toolpath, feed .

CNC milling, an abbreviation for Computer Numerical Control milling, is a transformative manufacturing process governed by computer software to direct machinery movement. Unlike additive processes such as 3D printing, CNC milling is subtractive, shaping solid materials into intricate forms by removing excess material.What is CNC milling and how does this subtractive manufacturing process work? This article explores how CNC milling machines work, what kinds of parts you can provide with milling and the best design practices for getting the most out of this type of CNC machining. Dive into the introduction to CNC milling with this beginner's guide. Explore the basics, CNC milling processes, and insights to kickstart your CNC journey.

CNC milling is a subtractive manufacturing process that combines traditional milling with computer numerical control (CNC) technology. It involves using a rotating cutting tool to remove material from a solid block of metal, plastic, wood, or other materials to create precise parts and products.

In this guide, we’re going to demystify CNC milling and break it down into bite-sized, beginner-friendly chunks. We’ll cover everything from the basics of how these machines work to the essential techniques you’ll need to get started. Milling is a manufacturing method using a rotating cylindrical cutting tool to remove materials from the workpiece and create a wide collection of CNC milled parts with different shapes, slots, holes, and dimensions, this is what is a CNC milling machine used for. CNC machines can mill any material—silicone plastics, wood, stainless steel and nonferrous metals—and are able to produce a wide range of components of varying complexity with consistent, high-quality results. From jewelry, to aircraft parts, to medical implants, many of the products in our modern life come to us through CNC machining.CNC milling machines manufacture medical devices, implants, and prosthetics in the medical field. These machines can produce intricate shapes and precise dimensions required for medical applications. CNC milling technology has revolutionized the healthcare industry, from dental implants to surgical instruments.

Computer numerical control (CNC) milling is a process in which automation and milling tools work together, removing material from a workpiece and producing a high-quality finished part or product. It is called a subtractive process, as opposed to the 3D printing additive operations that have become popular over the last decade. CNC milling is the same milling machining process that we know and love, with the addition of computer control. Milling is the cutting of a material like metal, plastic, or wood, using a rotating tool. Every aspect, like cutter toolpath, feed . CNC milling, an abbreviation for Computer Numerical Control milling, is a transformative manufacturing process governed by computer software to direct machinery movement. Unlike additive processes such as 3D printing, CNC milling is subtractive, shaping solid materials into intricate forms by removing excess material.

milling process step by

Order high precision CNC machining parts online with flexibility and certainty. ISO 9001 and 13485 Certified! Access a wide range of precision machining capabilities through our global network of manufacturing partners. 3, 4 and 5 axis CNC machining for both low and high complexity milling parts.

cnc can do what milling machine basics|cnc horizontal milling for dummies