cnc plastic milling machine What is CNC Plastic Machining? Understanding CNC Machines for Plastics. Plastic CNC machines are very intelligent. They do this by using computer programming to automate the process of machining. The equipment . Learn about the many common types of wall and ceiling electrical boxes for switches, outlets, light fixtures, ceiling fans, and junction boxes.

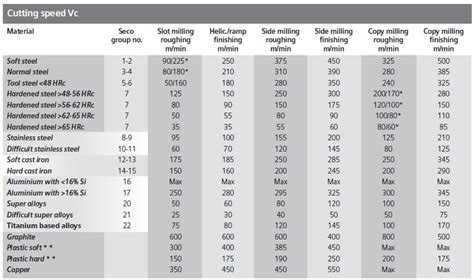

0 · teflon cutting speed chart

1 · plastic cnc machining near me

2 · lowest price cnc plastic machining

3 · end mills for plastic machining

4 · cnc plastic cutting near me

5 · cnc machine for plastic cutting

6 · best plastic for cnc milling

7 · best end mill for plastic

Metal electrical boxes are a popular choice for their durability and strength. They are available in different materials, including steel and aluminum. Here’s a breakdown of the two types of metal electrical boxes.

Miller Plastic Products offers CNC plastic milling and routing for various types of plastics, with high-speed automated machinery and precision inspection. Learn more about their . What is CNC Plastic Machining? Understanding CNC Machines for Plastics. Plastic CNC machines are very intelligent. They do this by using computer programming to automate the process of machining. The equipment . CNC milling is a common plastic machining method. this process uses rotary cutters to remove excess material from the workpiece. Proper choice of tooling and cutting speeds during machining will be essential to avoid . Plastic machining factories rely on computer-controlled devices to form raw materials into designated pieces. It is this technique, known for its accuracy, which works particularly well with plastics, giving one a cheaper .

A CNC machine is a powerful tool for automating complex and precise tasks, such as cutting, shaping, or milling materials. These machines have revolutionized manufacturing by filling . A CNC milling machine is a sophisticated piece of equipment that automates the process of cutting and shaping materials, such as metal, plastic, or wood. Standing for Computer Numerical Control, CNC milling leverages . The Fundamentals: CNC Milling for Plastic Parts. CNC (Computer Numerical Control) milling is a technology that uses computerized controls to move and operate milling . Milling machines with four axes or more and multi-axis milling machines are the most effective tools for making plastic components with intricate geometries. The following are the particular guidelines for the creation of .

Plastic Materials for CNC Machining. Several types of plastics can be used in combination with CNC milling and turning, but the choices are generally more limited compared to injection or other fabrication processes, . Computer Numerical Control (CNC) Techniques: CNC machining involves the use of computer-controlled machines to accurately and precisely cut, shape, and finish plastic components. This technology allows for high .Machining plastic with a CNC router - Miling, PVC, duroplastics, thermoplastics, plexiglass, POM, polycarbonate, PVC, PTFE, PE, PS, PA. . CNC Milling Machine Big Milling Machine RaptorX-SL up to 12000x3000mm; Industrial . What plastic is easiest to machine? The easiest plastics to machine are usually polycarbonate, ABS, polyoxymethylene (POM), and high-density polyethylene due to their flexibility and good machining properties. These materials are commonly used in CNC machining for their ease of manipulation and cost-effectiveness. . making it an excellent .

All our machines are perfectly suited for routing/milling any kind of plastic such as acrylic, PVC, POM, and others. You can mill all varieties of plexiglass up to about 30 mm thickness, and with our special polishing cutters you get a nearly polished edge.Plastic machining is a subtractive method of shaping and forming products by removing layers of material. This process is crucial for creating precision machined plastic parts, with the three most common techniques being turning, milling, and drilling.

Plastic milling using CNC machines brings a level of precision that’s hard to rival. When we compare this to traditional plastic shaping methods, the difference in the finished product’s accuracy is stark. Especially in industries like aerospace or medical devices, where a minor discrepancy can lead to significant repercussions, the .Complex Shapes from Advanced Materials We produce your parts with precision, accuracy and repeatability. Our team uses computer-driven CNC milling machines to create advanced plastic parts with tolerances of +/- .001 and the surface finishes as smooth as 15Ra. Secondary post-milling operations save you time and lower your production costs. We can add threads, finish [.] Polyoxymethylene (POM), popularly known as Acetal or by trade names like Delrin, is very important in the manufacturing industry due to its strength, low friction, and dimensional stability.This guide simplifies the POM machining process by providing necessary techniques and tips geared towards CNC machines. We aim to provide you with the . 3-axis CNC machine: Produces the most common parts that do not require multiple rotations, typically for drilling, milling, or machining prefabricated edges. 4-axis CNC machine: This allows the tool to access the other side of the part for cutting, slot milling, and other cuts. 5-axis CNC machine: capable of producing the highest precision parts and providing .

Plastic CNC machining is a manufacturing process that utilizes computer-controlled machines to remove material from a plastic workpiece, creating a precise final product. The plastic CNC machining can be attributed to several key benefits, including accuracy, precision, and the ability to maintain tight tolerances. Acrylic, also known as PMMA (Polymethyl Methacrylate), is a popular plastic for CNC machining machine part. It has several benefits that make it suited for a variety of machine part s. Benefits. Acrylic glass is transparent, impact-resistant, and weather-resistant. Its optical clarity makes it perfect for applications like signage, displays .efficiency of plastic milling. Milling plastic vs. metal When milling plastic, it is crucial to properly stabilize the part on the worktable and minimize vibrations from the high-speed cutting tool – these may result in chatter marks and decreased accuracy due to the shape wandering. Milling tips for plastic • Climb milling, also known as

Plastic CNC machining has a wide range of applications in multiple industries, mainly due to its high precision, high efficiency, and wide material compatibility. The common industrial applications of this process include: . What is the easiest plastic to CNC machine? POM produces less built-up edge during machining compared to other plastics .CNCTOPBAOS 1610 PRO CNC Milling Machine,with GRBL Offline Controller,3 Axis Desktop DIY Mini CNC Router Kit Engrave Carving PVC,PCB,Acrylic,Wood Cutting Engraving Machine CNC1610 Pro . 3 Axis Hobby CNC Router Machine GRBL Control, Plastic Acrylic PVC PCB Wood Mini Desktop Engraving Milling Carving Machine, Working Area 300x180x45mm. 4.1 out .When compared to traditional machining methods, plastic CNC machining holds many distinct benefits. Some of these benefits include: Precision: CNC machines can complete complex projects, such as those with very tight tolerances, with more precision and accuracy than traditional machining. Efficiency: CNC machines are able to operate for longer hours and with .

We supply CNC machines for cutting and milling plastic parts with working surface from 1600x2100mm up to 6200x2100mm, or custom. CNC multifunction system COMAGRAV. With a wide range of accessories allows milling, .Plastic Machining. When it comes to machining plastics, we take every aspect into consideration. Different plastics can and should be treated differently when they are being machined. We can help you understand the benefits and limitations of our many different material & machine types, while still meeting your exacting specifications.The milling machine is ideal for preparing plastic pipe samples (‘dumbbell’ or ‘dog bone’ specimens) for e.g. tensile tests and other kinds of elongation tests. The CNC miller is supplied with pipe samples templates according to ISO 6259 types 1, 2 and 3.CNC plastics can be used for a range of parts from prototypes to engineering models to end-use components. While plastics can be hard to machine, oftentimes their lightweight and denseness paired with simple geometries may be more suitable .

wood box stamped distributed by van speciality co

We have high-performance CNC plastics machining capabilities. These machining capabilities include milling, turning, drilling, and milling with a lathe. Our capabilities allow us to precision-machining plastic parts. We use high-precision milling machines to mill plastic components on a precision level of 0.0002” or better. CNC plastic machining provides a quick, efficient, and economic way for modern plastic parts manufacturing. The selection of plastic material is based on their properties and applications. . easy to wash, and dye. Nylon is commonly used to fabricate plastic fasteners and machine parts, cookware, and fabric, as well as parachute canopies .The CNC milling machines we manufacture can machine a wide range of materials. Among them, we have wood, non-ferrous metals like aluminum, foams, and plastics and composite materials such as resin.

These tools are designed to precisely shape and cut various materials such as metal, plastic, and wood. Our milling machine tools, including end mills, face mills, and indexable cutters, provide exceptional precision, efficiency, and durability. . CNC Manufacturing – Bringing New Revolution in the Industry Subscribe. Email Submit.Flexible and elastic plastics are more challenging to machine given their elasticity, tendency to deform under cutting forces, and resistance to tear and abrasion. . CNC plastic machining is a vital manufacturing process that leverages the unique properties of various plastics and the advanced capabilities of CNC machining to produce highly .

RATTMMOTOR 3018 Pro DIY CNC Router Kit, 3 Axis Hobby CNC Router Machine GRBL Control, Plastic Acrylic PVC PCB Wood Mini Desktop Engraving Milling Carving Machine, Working Area 300x180x45mm 4.0 out of 5 stars 108

teflon cutting speed chart

plastic cnc machining near me

lowest price cnc plastic machining

Sheet metal fabrication is used across many industries, offering flexibility and precision in creating everything from small components to large structures. This process involves cutting, bending, and assembling metal sheets to form various products, each suited to specific needs.

cnc plastic milling machine|cnc plastic cutting near me