20 ga sheet metal thickness bend The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for . A metal box spring — often made from metal, wood and animal skin — can elevate any home. Find 83 options for an antique or vintage metal box spring now, or shop our selection of 47 modern versions for a more contemporary example of this long-cherished piece.

0 · standard sheet metal bend radius

1 · sheet metal bending radius calculation

2 · protocase sheet metal bend radius

3 · how to calculate sheet metal bending

4 · aluminum sheet bending radius

5 · aluminum bend radius chart

6 · 18 gauge sheet metal bend

7 · 18 gauge bend sizes

$100.00

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for . A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius . The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake .The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our .

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect .

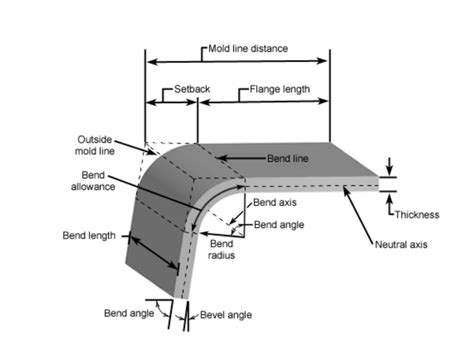

The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness . As a general recommendation, ±0.005 in. runs right at the limit of precision flat sheet metal in a job shop environment. For bent sheet metal, variation in the raw material thickness increases the recommended precision .

Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material .Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation, the radius can be near zero for thin sheet metal.

A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional lead time and tooling charges may apply.

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.

The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K).

As a general recommendation, ±0.005 in. runs right at the limit of precision flat sheet metal in a job shop environment. For bent sheet metal, variation in the raw material thickness increases the recommended precision to ±0.010 in. per bend. Layout Method for Sheet Metal “Sheet metal stretches when it bends” is an oversimplification. Your best bet when designing formed parts is to use the industry standard bend radius of 0.030”. This measurement ensures consistent, high-quality parts with solid structural integrity. We use 0.030" for all material thicknesses up to 0.125" (⅛") and increase the bend radius for thicker materials.Use this page to choose bend values for sheet metal that are both manufacturable and meet your needs.

standard sheet metal bend radius

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for stresses caused during forming operation, the radius can be near zero for thin sheet metal.

A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius should be 1t which is 2mm. The sheet metal bending radius is a critical value in sheet metal drawing that can be difficult to determine during the actual processing. This radius is dependent on the material thickness, the pressure of the press brake machine, and the width of .The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional lead time and tooling charges may apply.

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.The Bend Allowance Formula takes into account the geometries of bending and the properties of your metal to determine the Bend Allowance. You will need to know your Material Thickness (MT), the Bend Angle (B<), the Inside Radius (IR), and the K-Factor (K). As a general recommendation, ±0.005 in. runs right at the limit of precision flat sheet metal in a job shop environment. For bent sheet metal, variation in the raw material thickness increases the recommended precision to ±0.010 in. per bend. Layout Method for Sheet Metal “Sheet metal stretches when it bends” is an oversimplification.

sheet metal bending radius calculation

This 2022 Haas VF-2SS CNC vertical machining center is in plant, under power and available NextGen Control, HRT210SS Rotary Table, 4th & 5th Axis Drives & Wiring, Through-Spindle Coolant, Renishaw Probing, 12,000 RPM, HSK-A63 Taper, (30) HSK-A63 Holders, (2) Orange Vices, only 300 Cutting Hours.

20 ga sheet metal thickness bend|protocase sheet metal bend radius