3 axis cnc milling machine programming This video series is an introduction to manual programming of 3 axis CNC vertical milling machines. All videos are designed to build upon the previous one an. You are permitted to enter a box junction, stop and wait for oncoming traffic to pass, provided your exit road is clear. It is against the law to enter the box junction if your exit is not clear as you will be blocking the junction for other .

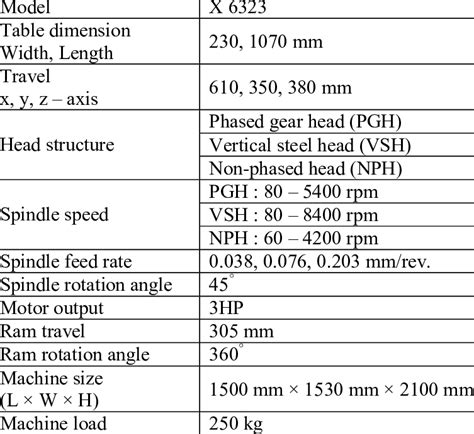

0 · specifications of cnc milling machine

1 · small 3 axis cnc mill

2 · datron cnc price list

3 · axis identification in cnc machine

4 · 3 axis vertical milling machine

5 · 3 axis manual milling machine

6 · 3 axis cnc table

7 · 3 axis cnc machine price

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.

mini cnc pcb router manufacturers

This video is a welcome and brief summary of what to expect from the three axis CNC mill manual programming course.This video series is an introduction to manual programming of 3 axis CNC vertical milling machines. All videos are designed to build upon the previous one an.

In this course, you will learn programming Real life parts in Mastercam. All below Topics are covered: Basic G-code Programming for CNC Mills. Lesson 4 - How to use and master the . A 3-axis CNC milling machine is a computer-numerically controlled, precision machine that utilizes computer commands to manipulate cutting tools through three linear .In this blog post, we will explore the fundamentals of programming a 3-axis CNC milling machine, from the basics to advanced techniques, allowing you to enhance your skills and maximize . Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis coordinate is given then the machine will only move in .

miniature electrical junction box

This video is a welcome and brief summary of what to expect from the three axis CNC mill manual programming course.This video series is an introduction to manual programming of 3 axis CNC vertical milling machines. All videos are designed to build upon the previous one an. You can get GRBL for free and flash it into an Arduino Uno (or Mega 2560, or Esp 32, or Rambo) and get a 3-axis CNC or laser controller. The only limitation is that GRBL performs open-loop control. So, it is best to use it with stepper motors.In this course, you will learn programming Real life parts in Mastercam. All below Topics are covered: Basic G-code Programming for CNC Mills. Lesson 4 - How to use and master the Dynamic Roughing & Finishing Toolpath. Computer Science Through Python Application.

A 3-axis CNC milling machine is a computer-numerically controlled, precision machine that utilizes computer commands to manipulate cutting tools through three linear axes: the X, Y, and Z. The Y axis represents the height, while the Z axis defines depth.In this blog post, we will explore the fundamentals of programming a 3-axis CNC milling machine, from the basics to advanced techniques, allowing you to enhance your skills and maximize efficiency in your machining projects. 1. Understanding CNC Milling Machines. What is a 3-axis CNC milling machine? 2. Introduction to CNC Programming. 3.

Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis coordinate is given then the machine will only move in the Z axis.3 Axis Milling routines to machine complex, contoured surfaces routinely encountered in mold making and aerospace applications. Request CAMWorks Demo! 3 Axis Milling modules are built on the core fundamentals of: Feature-based machining - Reduces programming time by as much as 90% compared to other traditional 3 axis CAM software.Introducing MR-1: the first affordable CNC Mill engineered to cut aluminum and steel. Only 95 for a limited time. The MR-1 Gantry Mill is a 3-Axis vertical CNC milling machine that was designed specifically for hobbyist, light industrial, and educational uses.The three-axis CNC machine tool is mainly controlled by x-axis, Y-axis and z-axis. Each axis has a stepping motor to control the operation of the axis. At the same time, x, y and z-axis are controlled by the much3 control system as a whole, and the step distance of each axis is accurately controlled.

This video is a welcome and brief summary of what to expect from the three axis CNC mill manual programming course.This video series is an introduction to manual programming of 3 axis CNC vertical milling machines. All videos are designed to build upon the previous one an.

You can get GRBL for free and flash it into an Arduino Uno (or Mega 2560, or Esp 32, or Rambo) and get a 3-axis CNC or laser controller. The only limitation is that GRBL performs open-loop control. So, it is best to use it with stepper motors.

In this course, you will learn programming Real life parts in Mastercam. All below Topics are covered: Basic G-code Programming for CNC Mills. Lesson 4 - How to use and master the Dynamic Roughing & Finishing Toolpath. Computer Science Through Python Application. A 3-axis CNC milling machine is a computer-numerically controlled, precision machine that utilizes computer commands to manipulate cutting tools through three linear axes: the X, Y, and Z. The Y axis represents the height, while the Z axis defines depth.In this blog post, we will explore the fundamentals of programming a 3-axis CNC milling machine, from the basics to advanced techniques, allowing you to enhance your skills and maximize efficiency in your machining projects. 1. Understanding CNC Milling Machines. What is a 3-axis CNC milling machine? 2. Introduction to CNC Programming. 3. Using an X, Y or Z code in a CNC program tells the machine to go to a specific location along those axes. Location changes can be in one or more axes. If only a Z axis coordinate is given then the machine will only move in the Z axis.

3 Axis Milling routines to machine complex, contoured surfaces routinely encountered in mold making and aerospace applications. Request CAMWorks Demo! 3 Axis Milling modules are built on the core fundamentals of: Feature-based machining - Reduces programming time by as much as 90% compared to other traditional 3 axis CAM software.Introducing MR-1: the first affordable CNC Mill engineered to cut aluminum and steel. Only 95 for a limited time. The MR-1 Gantry Mill is a 3-Axis vertical CNC milling machine that was designed specifically for hobbyist, light industrial, and educational uses.

specifications of cnc milling machine

small 3 axis cnc mill

datron cnc price list

$13.13

3 axis cnc milling machine programming|3 axis cnc table