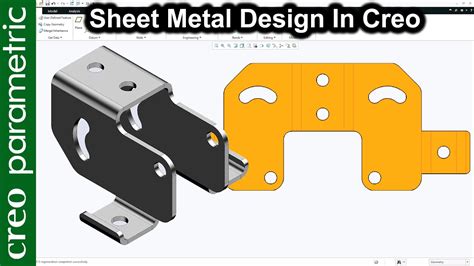

creo sheet metal training Sheetmetal Design using Creo Parametric is a comprehensive training course that teaches you how to create sheet-metal parts in Creo Parametric. The course builds upon the basic lessons you learned in Introduction to Creo Parametric . We find multiple types of junction boxes with their properties and advantages. For this reason, we categorize these electrical junction box types based on their features and applications. We will discuss each type in the following section to help you spot the best type for your requirements.

0 · sheet metal in creo parametric

1 · sheet metal creo tutorial

2 · creo sheet metal tutorial pdf

3 · creo sheet metal practice drawing

4 · creo sheet metal drawing

5 · creo sheet metal basics

6 · creo practice sheet metal models

7 · creo parametric sheet metal tutorial

Typically, keystock is made from metals like carbon steel or stainless steel, aluminum, brass, copper, and Monel®. Each type of keystock metal includes varying material grades that offer different benefits based on .

sheet metal in creo parametric

Most Designers using the Creo Sheet metal module have years of experience doing the same thing over and over. This course helps your designers expand .1: Introduction to the Creo Parametric Sheetmetal Design Process. 2: Sheetmetal Model Fundamentals. 3: Creating Primary Sheetmetal Wall Features. 4: Creating Secondary .Sheetmetal Design using Creo Parametric is a comprehensive training course that teaches you how to create sheet-metal parts in Creo Parametric. The course builds upon the basic lessons you learned in Introduction to Creo Parametric .Learn how to use Creo Parametric to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.

The Creo Parametric 8.0: Sheet Metal Design training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and .The Creo Parametric 5.0: Sheet Metal Design learning guide enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features.

crash bandicoot xbox metal boxes

In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall. Check out this video on Creo Sheetmetal Design from PTC Application Engineers Presenters: Lino Tozzi (Technical Specialist, Fellow) and Ryan ButcherView Schedule For Creo Parametric: Sheet Metal Design by Location, including Classroom-Based in North America, LIVE Online, or Blended Learning.Discuss modeling techniques such as starting out with non-sheet metal models and converting to sheet metal later to take advantage of shell features; Flexible modeling with respect to Sheet Metal; Use of top-down design to manage the fit of multiple sheet metal housings.

Most Designers using the Creo Sheet metal module have years of experience doing the same thing over and over. This course helps your designers expand and master the use of Creo Sheetmetal.1: Introduction to the Creo Parametric Sheetmetal Design Process. 2: Sheetmetal Model Fundamentals. 3: Creating Primary Sheetmetal Wall Features. 4: Creating Secondary Sheetmetal Wall Features. 5: Bending and Unbending Sheetmetal Models. 6: Modifying Sheetmetal Models. 7: Sheetmetal Setup and Tools. 8: Detailing Sheetmetal Designs

Sheetmetal Design using Creo Parametric is a comprehensive training course that teaches you how to create sheet-metal parts in Creo Parametric. The course builds upon the basic lessons you learned in Introduction to Creo Parametric and serves as the second stage of learning.Learn how to use Creo Parametric to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.The Creo Parametric 8.0: Sheet Metal Design training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features.The Creo Parametric 5.0: Sheet Metal Design learning guide enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features.

In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall.

Check out this video on Creo Sheetmetal Design from PTC Application Engineers Presenters: Lino Tozzi (Technical Specialist, Fellow) and Ryan Butcher

View Schedule For Creo Parametric: Sheet Metal Design by Location, including Classroom-Based in North America, LIVE Online, or Blended Learning.Discuss modeling techniques such as starting out with non-sheet metal models and converting to sheet metal later to take advantage of shell features; Flexible modeling with respect to Sheet Metal; Use of top-down design to manage the fit of multiple sheet metal housings.Most Designers using the Creo Sheet metal module have years of experience doing the same thing over and over. This course helps your designers expand and master the use of Creo Sheetmetal.

sheet metal creo tutorial

1: Introduction to the Creo Parametric Sheetmetal Design Process. 2: Sheetmetal Model Fundamentals. 3: Creating Primary Sheetmetal Wall Features. 4: Creating Secondary Sheetmetal Wall Features. 5: Bending and Unbending Sheetmetal Models. 6: Modifying Sheetmetal Models. 7: Sheetmetal Setup and Tools. 8: Detailing Sheetmetal DesignsSheetmetal Design using Creo Parametric is a comprehensive training course that teaches you how to create sheet-metal parts in Creo Parametric. The course builds upon the basic lessons you learned in Introduction to Creo Parametric and serves as the second stage of learning.

Learn how to use Creo Parametric to manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.The Creo Parametric 8.0: Sheet Metal Design training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features.The Creo Parametric 5.0: Sheet Metal Design learning guide enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. In this tutorial, you will learn a step-by-step approach to designing a sheet metal part in Creo Parametric. The tutorial covers the planar wall, extrude wall, flat wall, and flange wall.

Check out this video on Creo Sheetmetal Design from PTC Application Engineers Presenters: Lino Tozzi (Technical Specialist, Fellow) and Ryan Butcher

creo sheet metal tutorial pdf

creo sheet metal practice drawing

Typically, key stock is made from carbon steel or stainless steel, but can also be made from aluminum, brass, copper, monel, and even nylon, all with varying material grades. AISI 316 stainless is also available for marine applications. Are keys made of metal or aluminum?

creo sheet metal training|creo sheet metal drawing