how to fix warped sheet metal after welding Follow along as Nick shows you various methods that you can use when correcting a warped surface after welding for that PERFECT finish. The theme behind this. Dive into our online wholesale cnc milling parts products catalog on .

0 · warping sheet metal after welding

1 · how to repair warped sheet metal

2 · how to fix sheet metal after welding

3 · fixing warped sheet metal after welding

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy .

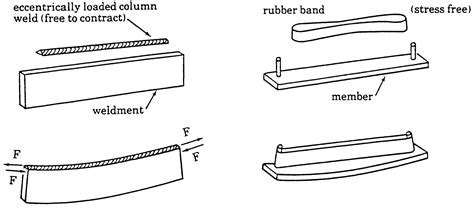

The fix is to use hammer on dolly hits to stretch the area where you welded. From the sounds of it your metal has been really messed up and you will have little hope of getting it perfect. It takes quite a bit of experience to know how to correct metal in the condition you .The root cause for metal distortions is expansion and contraction of the metal. The heating of the metal causes non-uniform stresses. You have the base metal been combined with filler metal. It is during cooling that the metal warps as it .

To fix warped sheet metal after welding, you can follow a few steps. Firstly, use a torch or flame to heat the warped area of the sheet metal. Once heated, rapidly cool the area . Our Friends from @CrucibleCoachworks stopped by to show us the BEST way to reduce or eliminate warping on sheet metal! Welder: https://www.eastwood.com/eastwood-tig. Follow along as Nick shows you various methods that you can use when correcting a warped surface after welding for that PERFECT finish. The theme behind this.

For the home hobby metal worker, the steps to straightening distorted metal after welding start before the first weld. Knowledge of how the metal reacts to heat and the best practices for planning the welding process can minimize the amount .Straightening steel after welding distortion. Welding distortion in steel is a nightmare to many welders, both novices and veterans. If you spot a slight bow, warp or buckle on your welds, take heart and follow these corrective . #ArtistKevinCaron #WeldingTips From http://www.kevincaron.com - Artist Kevin Caron shows tips and tricks to fix warping caused by welding ..Kevin Caron has.

Tips for sheet metal warping. Hey guys. I'm a hobby welder and I'm about to have to do a patch panel on an inner fender with 18Ga steel. I figured I should do some practice runs on some . Table of Contents. How To Fix Warped Sheet Metal After Welding. 1. Hammering. 2. Heat Straightening Method. 3. Hot Mechanical Straightening Method. 4. Hot Working Method. How To Prevent Metal From Warping During . one of the hardest parts of working on sheetmetal is knowing when it needs to be shrunk or stretched, when a weld is involved it is easier, because as a rule the metal shrinks after welding, so hammering the weld will usually get you back into shape. there may be high areas just outside the weld area, but don't be fooled, it's just the panel .

11. Sheet Metal Tips. As mentioned in the introduction, sheet metal work is a different animal than steel beams. Any of the above practices can be useful in mitigating distortion in sheet metal, but there are additional practices .

warping sheet metal after welding

Table of ContentsHow to Fix Warped Sheet Metal After Welding?Understanding Warped Sheet MetalTools and MaterialsFixing Warped Sheet MetalBenefits of Fixing Warped Sheet MetalWarped Sheet Metal vs. . Picture that I have a frame about 2' x 3' of 1/2" square steel tube. I put a sheet of 18 gauge steel sheet over it and weld around the edges to the tube frame. Now the sheet has significant waves in it from the uneven heating while welding the edges. Could the welding around the edges been planned out and done so as to Roger showing how to flatten 3mm steel plate after weldingRoger Cook explaining how he uses hot and cold to tighten the steel plate to remove heat deformatio. After welding, it is important to remove any welding residue, such as slag or spatter, from the surface of the weld. These residues can contribute to contamination and affect the weld quality. Using appropriate cleaning methods, such as wire brushing or grinding, ensures a clean surface and reduces the risk of defects and warping.

My theory is the stress causing the metal to distort came from the welding heat so if I remove the metal around the weld area the rest of the hood will relax back into shape. Then maybe I can find a real welder to weld in a repair strip. Is this a good theory or wishful thinking? I really need to fix this one, these old hoods are hard to find. i would have to disagree w gearhead 1952. when i use a mig welder to install patch panels i leave a gap the size of a thin cut off wheel. wqhen do a gas weld or tig weld you can go with out a gap. with a mig weld you are adding metal ever time you pull the trigger. you must give that metal a place to go. i think the cut offs i use are like 1/32 .

Me and the other dude have stainless tig sheet metal experience prior to joining the hall to do pipe. But yea all in all we were rushing. . Reply reply dunk0ff • The lid didn’t warp from welding the ring on, it warped from pushing down hard af with hole saw while it was still hot / warm. It was about 3-4 mins after I laid the last stitch .

I had tried this before with 40-45A but I feel that was just letting to much heat in the metal. I kept it at 65 and realllllly zoomed through the welds with a fast travel speed doing 1" fills at a time with 0.045" filler wire and dousing with the wet rag after each inch of weld to keep it cool. The fact is that no matter how good or careful you are, metal WILL warp when you’re welding on sheet metal. We’ve heard all of the tricks in the book, but none of them completely stop the warping; only reduce or control it. The secret is that the heat and cooling from welding will shrink the metal around the weld seam to some degree. Re: Help requested - How to fix warped 1/8" plate We solved this on our Engineering Drawings by adding a note to "Weld in the Constrained Condition." Next time try clamping the 1/8" plate down on all sides with clamps reaching as . The metal has to do something if there is to much of it. I don't think the bow is a heat warp, I think it's a buckle caused by to much metal at the top caused when the bottom portion of the transom shrunk after the weld cooled. I don't see why it couldn't be cut and welded, they repair aluminum boats all the time.

This is why a lot of sheet metal doors have hat sections or stiffeners spot welded in prior to having the edges or other welding done to it. Sometimes the stiffener or hat section is stich welded in.. You could weld in a stiffener across the warped face . I'm not saying don't ask or even try and fix it, i'm saying if it's to sell make another and practice on that piece. Realistically it isn't stiff enough thats one reason why it's warped, look around at things made with metal that size .This problem is particularly acute when welding sheet metal because it will be both thinner and lighter, making it even more prone to warping. The positive aspect of this is that it is easier to sand, grind, or buff, making your preparation . Im no ace at this, actually im pretty crappy, but i you either hit the warped part w/ the torch (w/ a small tip) and then go at it w/ a rag damped in cold water, or buy a shrinkin disk and attak the panel. you need to cool the metal after the shrinkin disk just like if you were torchin it, you can use compressed air too.

Grades And Characteristics Of Stainless Steel Welding. Stainless steel is a widely used material in various industries due to its corrosion resistance, durability, and aesthetic appeal.However, welding stainless steel presents several challenges.One of the main challenges is the wide range of stainless steel grades available, each with its own unique characteristics . How to straighten bent metal after welding

Then follow standard sheet metal patching procedure. Figuring you don’t want to metal weld, you can use epoxy (or similar materials) for a pretty durable fix. Alternatively for a quicker, easier fix there are specialty tapes you can buy (like eternabond), but . In this blog post, we’ll discuss three ways to fix broken metal without welding. Keep reading for more information! 10 ways to fix broken metal without welding. 1. Use a strong adhesive. There are many strong adhesives on the market that can be used to bond metal together. Just make sure to follow the instructions on the product you choose .Learn how to fix warped sheet metal after welding with these simple tips. Avoid common mistakes and ensure a professional finish. #trimthatweed Need a fix for "Oil Canning" auto body panels? In this very short video I will show you how to repair, shrink sheet metal and stiffen body panels the easy w.

I'm still beginning on welding and I have a problem with my first project. I'm building a sliding gate frame that will be covered with wood. For that I choose to use C channel 2mm thick so that I can have the nuts be inside the channel. After I tacked the corners I welded it distributing the heat, it was all fine while it was on the ground, or laying againt the the wall (like the frame . 7 Common Sheet Metal Welding Problems and How to Fix Them Sheet metal parts are coveted for their simplicity, affordability and aesthetically pleasing build from thin plates of metals. The process efficiency, ease of modification, malleability and lightweight also make them ideal for a wide array of applications. Sheet metal fabrication .

You'll never warp another panel again after watching this video. This is a realtime, step by step demonstration that shows how to mig weld sheet metal withou.On this episode of Make It Kustom I show you how to butt weld thin sheet metal body panels using tig welding. This is a fender repair on a customers Fox body.

how to repair warped sheet metal

Dive into our online wholesale cnc machined parts products catalog on globalsources.com! Source over 17411 cnc machined parts for sale from manufacturers with factory direct prices, high quality & fast shipping.

how to fix warped sheet metal after welding|fixing warped sheet metal after welding