mig welding sheet metal with a 100 welder Mig welding, also known as Gas Metal Arc Welding (GMAW), is a popular method for welding sheet metal due to its speed and versatility. It uses a continuous solid wire electrode . Search for used cnc waterjet cutting. Find Flow, Mitsubishi, JET, MultiCam, A&V Waterjet Tech, Cobra, and Soitaab for sale on Machinio.

0 · welding 20 gauge sheet metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · mig welding travel speed chart

4 · mig welding thin metal videos

5 · mig welding sheet metal basics

6 · mig welding automotive sheet metal

7 · best welding for thin metal

Below is a list of used laser cutting machines for sale, updated daily. Please utilize the brand table and/ or advanced filters to narrow down your search. If you don’t find the machine you are looking for, please provide us more details using the Machine Locator or give us a call!

In this video I demonstrate how to set up your mig welder so you can weld thin sheet metal. We also showed in this video how to make your pattern, fit and weld it in. I demonstrated this.

cnc extrusion parts

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc . Mig welding, also known as Gas Metal Arc Welding (GMAW), is a popular method for welding sheet metal due to its speed and versatility. It uses a continuous solid wire electrode .A MIG welder with infinite adjustability will be the best option for welding thin metal sheets. Also, a multi-purpose welder will allow you to adjust the settings to meet the requirements and match your desires.

welding 20 gauge sheet metal

Yes, sheet metal with a thin gauge can be welded using a MIG welder. Although TIG welder is the top choice for welding thin sheets because they require higher precision of heat input, MIG welding is also very efficient. Preventing burn-through and warping when welding sheet metal is all about controlling the heat. Choose the right welding process and filler metal, and follow these common tips to help ensure success.

These documents can provide the welding parameters necessary to complete a weld correctly and consistently for a given application and joint design. A WPS offers the recommended operating window — or maximum and minimum . In this comprehensive guide, we’ll delve into the intricacies of MIG welding sheet metal and explore the ideal settings for different metal thicknesses. From voltage and wire feed speed to shielding gas selection, we will unravel . MIG welding sheet metal requires precision and the right tools. Here’s a streamlined approach, complete with examples, to help you achieve perfect welds on thin metals. 1.MIG Welder For Thin metal. To prevent burn-through and wrapping of sheet metal, you will need a proper MIG welder, filler metal, and shielding gas. When choosing a MIG welder for thin metal, you can look for something other than .

welding 14 gauge sheet metal

welder settings for sheet metal

This 140-amp MIG welder has everything you need to get started, just add a bottle of shielding gas. It includes a precision metal drive motor, regulator with hose, Tweco-style torch, tips and accessories, modern features and technology. . New and improved features and technology to weld sheet metal up to 3/16". MIG Answered by: Anonymous .

To weld sheet metal with solid wires, use electrode positive (EP, or reverse polarity). Don’t attempt to weld thin materials like sheet metal with flux-cored wires, which put more heat into the base metal. TIG welding sheet .

Eastwood Co makes a great low cost Flux Core welder that can MIG weld with a future purchase of a gas regulator, hose, appropriate MIG wire, and gas tank. . Once you settle on your welder, flux core welding thin sheet metal is pretty easy. Load the wire into the welder, feed it into the torch feeder, and lock it in. .

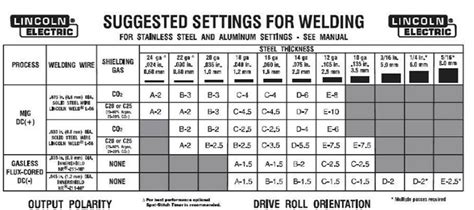

I need to weld some 22 Gauge sheet metal with my Lincoln Easy Mig 180. Question is, does smaller wire burn hotter because there is less material going in to cool the puddle? If i look on the chart on the welder, it says to use settings 2-B for 22 gauge either .025 or .030 wire (100% co2). So if i don't change the settings between the 2 wires, won't the thinner . MIG welders are best recommended for these applications as MIG welding is the most common procedure used by people who make and work with sheet metal. Is it possible to stick weld sheet metal? Yes, you can stick weld sheet metal less than ⅛’’ thick, but you will need the right machine and a good set of welding skills to get the job done. In this video I show you how to set up your MIG welder and also prepare your metal for the plug welding process. I try to walk you through the entire process. The miller at work is, to me, worthless for anything more than sheet metal. What I really hate with it and honestly most 110v welders is no initial heat when spot welding, they and this particular miller have a hard time building heat in a spot weld. By the time the welder is actually melting and fusing metal the plug is filled.

You don't need TIG for sheet metal; you just need the right settings and a lesson—like all of us do. Most auto body shops don't use TIG for panels; they use MIG, and that says a lot. Your machine can work fine, with a few operator tricks. The biggest mistakes with sheet metal welding are gap and heat. Flux core is way harder to do on thin metal. However, you shouldn’t use pure carbon dioxide as a shielding gas for MIG welding thin metal. It’s easy to burn through a light gauge and distort the sheet. To weld thick steel sections, you can use 100% carbon dioxide. If your MIG welder has an .

For thin sheet metal welding it can be 30 ampere while for thicker (e.g. 1/8” square groove weld)- it can go up to 220 ampere for example. GMAW-S gives low heat and makes it easy to use in all positions on sheet metal, low carbon steel, low alloy steel, and stainless steel sheet metal from 25 gauge (0.02 inch or 0.5 mm) to 12 gauge (0.1 inches or 2.6 mm). Thanks for Watching!!!High PSI tv Merchandise Available Below:http://highpsitv.bigcartel.comHelp me get to 100,000 Subs. Yea I know its a big number.Set your.

With a MIG welder, you can weld galvanized steel with great results if you remove the coating. If you wish to weld over the coating, a MIG welder will provide satisfactory results if you use flux-cored wires. . Most often the metal underneath is mild steel, but on rare occasions, you may have a harder-to-weld metal. Here is an article on how . 3. Adjust Your Torch Angle. Changing the torch angle when MIG welding goes a long way to preventing burn-throughs. Make sure you adjust the angle to shorten the distance between the tip and the metal, no matter the welding position you work in.This will make the arc more stable, giving you more control over the weld and lessening the chance of burn-through. The copper helps to absorb the heat being pumped into the metal, and because it’s a dissimilar metal, the weld won’t stick, so you can pull it out when you’re done. Post Weld. When you’re working with sheet metal, .

Hi to everyone I'm new to welding end the forum looking for advise I want to by welder mainly for thin sheet metal and bodywork I'm looking at few options can you give your advice and opinion Lincoln Power Mig 180C ; Lincoln Electric Powertec 191c Mig Welder ;Millermatic 180 and Portamig 185.

mig welding travel speed chart

Then I came across this video from a guy who tested out the Parkside PMSG 200 A1 welder on thin sheet metal 0.7mm thick, which is probably what I'll be using to repair rust spots on my car. The Parkside PMSG . In this video, we're going to show you some tips and tricks to mig welding sheet metal that no one talks about! If you're new to the art of welding, or you j. Shielding gas is critical to MIG welding; inappropriate or insufficient gas can cause major weld problems.. The most crucial factor is that the shielding gas you select must have less than 5% carbon dioxide content.. When too much carbon gets into the weld and into the base metals, corrosion resistance will decrease. how to spot weld with a mig welder

I keep blowing through my thin sheet! Andy gives helpful insights and tips to MIG weld thin sheet metal.KINGMETALS.com

It can weld 24 gauge thick sheet metal for thin sheet metal that can serve a welder to work on doors, floor panels, wheelbarrows, garden wagons, and other small but useful applications. When you run the machine at 45 amps output, it gives you a 60 % duty cycle, regular and continuous 6 minutes of straight welding. In this video I show how to set up your mig welder to be able to weld on super thin metal with out warping it. I go through step by step comparing how to pre.Yes, you can weld sheet metal with a MIG welder. Just be sure to use the right settings and have proper ventilation. Actually, MIG welders are one of the best type of welder for sheet metal because they are less likely to cause warping and distortion. They are also easier to use than TIG welders and can be used for a variety of projects.

On this episode of Make It Kustom, I finish patching Kristina’s fenders for her body dropped 1960 Cadillac. We show you step-by-step how these panels are mad. Paul is back to sharing tips on how to MIG weld thin gauge material (thin carbon steel).Download the WELD™ APP, join the welding community, find welding res.Demonstrating the basics of mig welding sheet metal to Zach who is a first time beginner 🔥@lincolnelectrictv IF YOU ENJOYED WATCHING:subscribe, leave a comm.

mig welding thin metal videos

They have been known for making economical and reliable machine tools .

mig welding sheet metal with a 100 welder|best welding for thin metal