18 gauge sheet metal I'll be mig welding new sheet metal to the floor and some frame work also. Problem is ~ I DIDN'T KNOW THE GAUGE OF THE SHEET METAL ON MY CAR Could it be 22 gauge or 24,26 Can you guys give me some help on this one please Also need help with some sandblasting questions but I'll leave that for another posting. THANKS AGAIN GUYS GOD . In-Ground Post Decay Protection, 12-Pack. Fence Post Braces & Accessories at Tractor Supply Co. Buy online, free in-store pickup. Shop today!

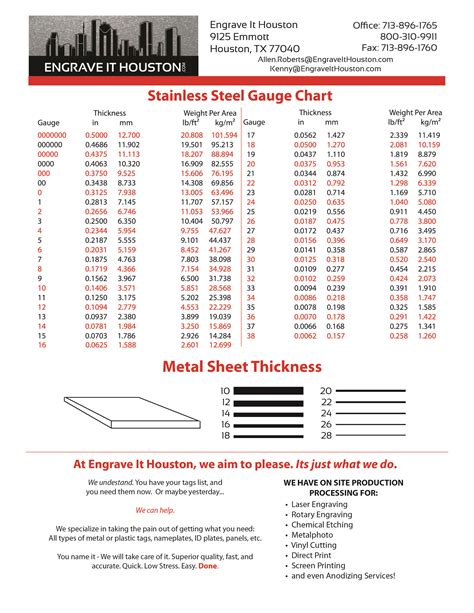

0 · sheet metal gauge chart

1 · metal plate gauge thickness chart

2 · 18ga sheet metal near me

3 · 18 gauge to fraction

4 · 18 gauge sheet metal thickness

5 · 18 gauge sheet metal near me

6 · 18 gauge galvanized steel sheet

7 · 18 gauge galvanized sheet metal

A percussion instrument that consists of a set of tuned wooden bars arranged like a piano keyboard. A series of hollow tubes beneath the bars allows the sound to resonate. The bars are struck with mallets.

Sheet Metal Lowe's and other suppliers got to be just too expensive. I can order 3 times the metal + shipping from cutsmetal .com for what Lowe's wants for 1 sheet. Another good source for metal sheets on car projects is www.eastwood.com-18 gauge 24x32 is just .00. I am working on a 39 Sedan. I have bought a 4 x 10 sheet of 18 gauge cold rolled steel for floor patches and mainly flat stuff, but i need something more flexible to make contoured panels. The cold rolled stuff is just to hard to bend easily. I was told to get a roof off of a car. I cut one off of a 85 Buick Regal, but it is a thinner metal. I'll be mig welding new sheet metal to the floor and some frame work also. Problem is ~ I DIDN'T KNOW THE GAUGE OF THE SHEET METAL ON MY CAR Could it be 22 gauge or 24,26 Can you guys give me some help on this one please Also need help with some sandblasting questions but I'll leave that for another posting. THANKS AGAIN GUYS GOD .

22 is about standard on "newer" stock and can be welded with a "good" wire welder on likely the lowest setting but be aware of burn thru's. So back off with the gun to reduce the heat some. If it's galvanized metal or e-coat,that will have to be ground down to bare metal to weld. What do you guys think is the best way to handle this task. I plan on riveting the sheet metal in most of the car but the trans tunnel, I'm guessing, will probably have to be made from several pieces and welded together. I'm using 18 gauge sheet metal for the tunnel and will have to hand form them as I don't have a roll. To weld sheet metal you need a tig or mig with the gas bottle. These to welder you can weld at lower temps. Now you can go to power block tv and look at welding body panels. Which is the stitch or tack method. You tack in the panel or patch. Then you tack in a star pattern to keep the metal from warping and pull from one side to the other. But 18 gauge cold roll is just the sweetest stuff for fabricating pans. We got 4 x 10' sheets for the shop I work at on the last purchase and I don't know the price. But it could be high and still beat the alternatives.

Then 18 gauge sheet metal is cut to match the rectangle and a circle just slightly larger than the fan diameter is drawn and cut out: Weld the sheet metal to the rectangle and weld on mounting tabs: And install to check all clearances: No big deal. Well after 4 hours of trying to adjust it every way possible (and ruining about 4 feet of 18 gauge sheet metal). I am officially declaring this thing a cheap piece of Chinese sh#t. The problem is that the table that holds the bottom cutting blade is bending under the pressure of even a 3" wide piece of sheet metal. The brake . well in that case then I think I would go with an 18 gauge sheet metal and make some stiffeners by bending strips into angles to be tacked to the underside of the floor..be sure and put some reinforcing in way of the seat belt attachments and at the points where the cab bolts down..if you can maintain the rockers on the cabs as they provide good strength to the cab . Sheet Metal Lowe's and other suppliers got to be just too expensive. I can order 3 times the metal + shipping from cutsmetal .com for what Lowe's wants for 1 sheet. Another good source for metal sheets on car projects is www.eastwood.com-18 gauge 24x32 is just .00.

I am working on a 39 Sedan. I have bought a 4 x 10 sheet of 18 gauge cold rolled steel for floor patches and mainly flat stuff, but i need something more flexible to make contoured panels. The cold rolled stuff is just to hard to bend easily. I was told to get a roof off of a car. I cut one off of a 85 Buick Regal, but it is a thinner metal. I'll be mig welding new sheet metal to the floor and some frame work also. Problem is ~ I DIDN'T KNOW THE GAUGE OF THE SHEET METAL ON MY CAR Could it be 22 gauge or 24,26 Can you guys give me some help on this one please Also need help with some sandblasting questions but I'll leave that for another posting. THANKS AGAIN GUYS GOD .

22 is about standard on "newer" stock and can be welded with a "good" wire welder on likely the lowest setting but be aware of burn thru's. So back off with the gun to reduce the heat some. If it's galvanized metal or e-coat,that will have to be ground down to bare metal to weld. What do you guys think is the best way to handle this task. I plan on riveting the sheet metal in most of the car but the trans tunnel, I'm guessing, will probably have to be made from several pieces and welded together. I'm using 18 gauge sheet metal for the tunnel and will have to hand form them as I don't have a roll. To weld sheet metal you need a tig or mig with the gas bottle. These to welder you can weld at lower temps. Now you can go to power block tv and look at welding body panels. Which is the stitch or tack method. You tack in the panel or patch. Then you tack in a star pattern to keep the metal from warping and pull from one side to the other.

But 18 gauge cold roll is just the sweetest stuff for fabricating pans. We got 4 x 10' sheets for the shop I work at on the last purchase and I don't know the price. But it could be high and still beat the alternatives. Then 18 gauge sheet metal is cut to match the rectangle and a circle just slightly larger than the fan diameter is drawn and cut out: Weld the sheet metal to the rectangle and weld on mounting tabs: And install to check all clearances: No big deal. Well after 4 hours of trying to adjust it every way possible (and ruining about 4 feet of 18 gauge sheet metal). I am officially declaring this thing a cheap piece of Chinese sh#t. The problem is that the table that holds the bottom cutting blade is bending under the pressure of even a 3" wide piece of sheet metal. The brake .

dc wire junction box

sheet metal gauge chart

metal plate gauge thickness chart

Whether you're creating intricate designs in wood, precise cuts in metal, or detailed engravings on glass and plastic, CNC routers offer unmatched versatility and accuracy. In the past, achieving such precision manually was arduous and often led to inconsistent results.

18 gauge sheet metal|18 gauge sheet metal thickness