safe metal fabrication Learn everything about Metal Fabrication Safety for your metal shop big or small. Let's discuss precautions, hazards and safety rules when working with metal. CNC motors are the heart of any CNC machine. The size and type of motor can define a CNC routers precision, speed, and accuracy. There are two primary classes of motors used on CNC .

0 · sheet metal fabrication safety

1 · metal fabrication safety standards

2 · metal fabrication safety requirements

3 · metal fabrication safety hazards

4 · metal fabrication safety clothing

5 · metal fabrication safety

6 · how dangerous is metal fabrication

7 · fabrication shop safety

Each type of electrical box is designed for a specific use. Below are the most common electrical boxes, like the outlet box, junction box, light switch box, and fan box, as well as different gang boxes, from single gang and 2 gang, up to 3 gang, 4 gang, and beyond.

Learn everything about Metal Fabrication Safety for your metal shop big or small. Let's discuss precautions, hazards and safety rules when working with metal. Metal fabrication entails the process of erecting metal structures by cutting, bending, and assembling the raw material. It is imperative that safety is taken into .

Steel fabrication and erection procedures involve several key safety concerns, but by managing the safety risks within the work environment, you can easily prevent injuries.Knowing how to keep your shop compliant with OSHA regulations can prevent injuries, save lives, and protect your company’s bottom line. Here are the top five OSHA citations with the highest penalties in fabricated metal product . Metal fabrication involves the use of heavy machinery and hazardous materials, making it critical for facilities to prioritize safety. Workers in a fabrication shop can put themselves at risk of injury when they neglect safe . Discover essential safety measures for your steel fabrication project. From training to equipment inspection, ensure worker safety and project success.

sheet metal fabrication safety

The most effective method of keeping your metal fabrication shop safe is 3 pronged: identification, prevention, and safety culture. To make your shop a safe workplace, first, you need to conduct a thorough safety assessment to identify .

bending and welding sheet metal

Metal fabrication entails the process of erecting metal structures by cutting, bending, and assembling the raw material. It is imperative that safety is taken into consideration when working with metal fabrication. Occupational .An iron plant in St. James Parish, Louisiana temporarily shut down when one of its workers died in an onsite accident; an El Paso, Texas metal fabricator was fined over 0,000 for numerous safety violations after a worker required .

Hickey Metal Fabrication is a nationally-recognized fabricating powerhouse. Increase the scope and scale of production through our State-of-the-art Automation in our seven-plant, 400,000+ square foot facility. Hickey Metal .From sheet metal fabrication to kitting services and assembly, our team works tirelessly to make sure you always have the solutions you need. . so much more needs to be done to make sure our troops are as safe as possible. At Cardinal MetalWorks, we provide CARC painting and C4I parts for a broad range of mission-crucial equipment and . Workers in a metal fabrication shop should familiarize themselves with these tips for staying safe in a metal fabrication shop. Wear Protective Equipment. Shop owners should inform workers of all safety requirements and regulations and provide or require appropriate personal protective equipment. This may include eye protection, face shields .

The new metal fencing feels secure and private, and our neighbors on both sides have complimented us on it. We're so happy with the work and it really has improved the look of the whole property!" . Blackhill Fabrication Co. is a premier artistic welding and fabrication family-owned business located in the beautiful city of Tucson, Arizona .Commercial Metal Fabricators is an industry leader in metal fabrication, forming and machining. We have the capabilities to handle any size metal fabrication project. We are ISO certified and work with businesses and federal agencies. CMF is . #FabricationTips #WeldingTips #KevinCaronArtFrom http://www.kevincaron.com - Artist Kevin Caron shares some of the ways he stays safe when creating his metal.Oil & Gas Systems master alloys fabrication, metal fabrication, pipe fabrication, stainless steel fabrication, steel fabrication 1 Comment on General Guide for Metallic Pipe Stainless Steel Fabrication Assembly and Erection

Metal fabrication involves working with various types of metal materials and machinery, which can present a number of safety hazards. Knowledge and b2b portal for construction and . Follow Safe Operating Procedures. Before operating metal fabrication equipment, read the manufacturer’s instructions and follow safe operating procedures. .Fabricators who understand the ROI of a safe, productive shop floor emphasize ongoing equipment training and safety best practices such as: . Experienced metal fabricators make safety best practices an integral part of their documented quality control (QC) program. As part of the QC program at Southern Metal Fabricators, every employee .At Hot Metal Fabrication, our vision is to be the leading provider of high-quality, precision-engineered products for specific vehicles. We aim to empower car enthusiasts by delivering innovative solutions that enhance performance, style, and durability. Through exceptional craftsmanship and customer support, we strive to exceed expectations .

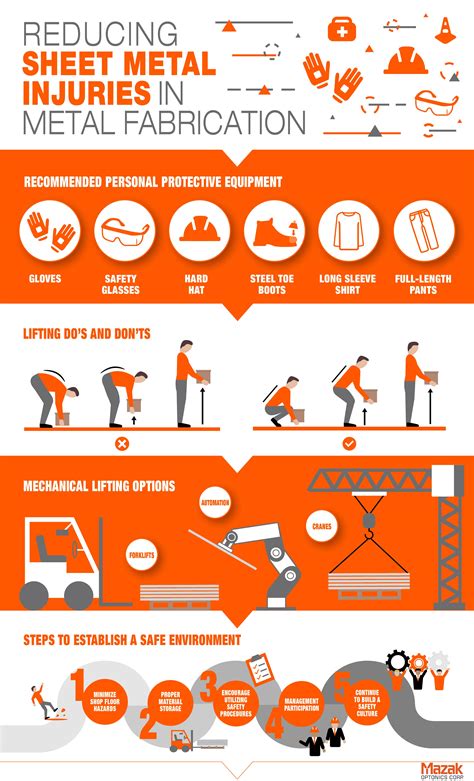

Poor Guarding and lack of safety equipment – Durning the metal fabrication processes lots of people don’t use all the personal protective equipment or they only use some. These can vary depending on the work you do or where, or on what are you working. From Helmets, gloves, boots, face shields, protective glasses welding helmets, aprons, and respirators.Fabrication Without Compromise Precision Manufacturing & Metal Fabrication Services Our in-house manufacturing services include: Waterjet Cutting. Fast, cost-effective, and accurate. Metal Fabrication. Washington-state certified welders on staff.

3 Most Common Safety Concerns in Metal Fabrication. First, let’s cover the most common safety concerns within the metal fabrication industry, their costs, and an umbrella method of solutions. 1. Machine Guarding. According to OSHA .KAKUNGULU & SONS METAL FABRICATORS LTD is a registered company based in Kampala Uganda, Rubaga division, fully licenced to carryout its activities in the metal fabrication and engineering industry and we have been in the .-Mobile Welding & Repair - AWS Certified Welding Inspection -Shop Fabrication -Equipment, Installation and Consulting We'll get the job done right - the first time! Saftey and quality come standard at Safe Welds LLC. Our welding services .For further information on the selection of appropriate Personal Protective Equipment, please refer to the Safe M anual Handling of Chemicals in the Automotive Industry for a seven step selection guide (pgs 36 – 41). 42 W ORKSAFE VICTORIA / A GUIDE TO SAFETY IN THE M ETAL FABRICATION INDUSTRY OTHER USEFUL GUIDANCE M ATERIAL The fabricated .

The metal fabrication and welding industry has long been a sought-after service in our economy. This is especially true in North Texas, where manufacturers, industrial facilities, transportation companies, heavy-duty parts suppliers, and more rely on highly-trained specialists to cut and manipulate metal with surgical precision to finish complicated projects quickly and efficiently. All of it designed to allow fabricators to operate the systems safely and abide by ANSI Z136.1, Safe Use of Lasers, an OSHA-recognized standard. Earley described hand laser welding safety mitigation using two scenarios, the best and the worst.

OSHA has specific regulations for safe operations in metal fabrication. Knowing how to keep your shop compliant with OSHA regulations can prevent injuries, save lives, and protect your company’s bottom line. Here are the top five OSHA citations with the highest penalties in fabricated metal product manufacturing for the 2022-23 reporting period.Specialties: 24 hour mobile welding services! - Iron Gate repair - Automatic Gates - Fabrication - Entry Systems - Instalation and repair - Aluminum, stainless, etc. (All metals) - Torch and Plasma cutting No job too big or too small, I can do it all !Work includes manufacturing bridges, oil rigs, ships, petro-chemical installations, cranes, platforms, aircraft, automotive and machinery parts, sheet metal enclosures, equipment supports, and anything that can be fabricated out of metal. Fabricators can work alone or in teams, in factories or on operational sites.Fabricators use a large range .Custom Welding & Metal Fabrication Services in Salem, Portland, Aumsville and Surroundings. 971-388-7930 [email protected] Aumsville, OR; CCB#242003; 971-388-7930 [email protected] . designed to maximize utility and storage. Engineered for strength and versatility, they provide a safe and efficient solution for transporting tools and .

Metal fabricators can work with a variety of metals, including steel, aluminum, copper, and brass. They are also responsible for finishing processes such as sanding, grinding, and polishing. We’re about to begin, but first, here are some other Metal Fabricator related resume examples: . Maintained a clean and safe work environment. By prioritizing safe practices in metal sheet fabrication, businesses can create a work environment where employees can perform their duties with confidence, knowing that their safety is paramount. Safety First is not just a slogan but a way of life in this industry, ensuring that productivity and quality go hand in hand with the well-being of .

As the sheet metal fabrication industry continues to evolve and grow, the importance of prioritizing safety cannot be overstated. This process, which involves the manipulation of heavy, sharp, and often hot materials, presents a unique set of challenges that require a .

There are various types of sheet metal operations for making products. Some basic operations list is below. Blanking Punching; Piercing ; Cut-off ; Parting off ; Notching ; Bending; Let we will discuss the types of sheet metal operations in detail. What Are the Basic Properties of .

safe metal fabrication|metal fabrication safety requirements