3d scan sheet metal parts 3D laser scanning offers tremendous time savings and cost benefits for the metal fabricating and sheet metal forming industry. Most importantly, it provides the ability to reverse engineer and . CNC machining involves several steps to transform a digital design into a physical part. Here’s a simplified overview of the process: Design: A 3D model of the desired part is created using computer-aided design (CAD) software. The design specifies the dimensions, shapes, and features of the part.

0 · industrial 3d scanner

1 · handheld 3d scanner

2 · atos 3d scanners

3 · artec 3d scan

4 · 3d scanning inspection solutions

5 · 3d scanners for sale

6 · 3d scanner for inspection

Today (Wednesday), operation begins at 8:00 am and ends at 8:00 pm. Read the specifics on this page for Kmart Westfield Bondi Junction, NSW, including the trading hours, address description, direct contact number and additional details.

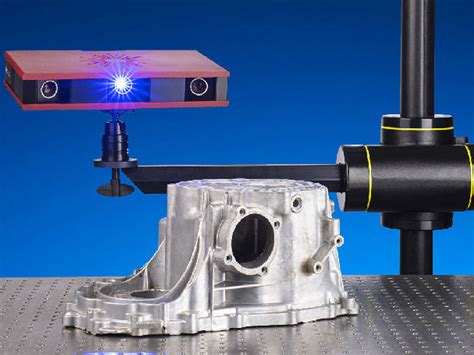

Get to know the ATOS Q with ScanBox, an automated solution for scanning and analyzing sheet metal parts. Request your live demo!3D laser scanning offers tremendous time savings and cost benefits for the metal fabricating and sheet metal forming industry. Most importantly, it provides the ability to reverse engineer and .Manufacture your molded plastic parts with the ease and efficiency 3D scanning provides. Get it right the first time – and every time after – with high-precision inspection of sheet metal stamping. Create and cast complex shapes with .Capture 3D the leader in 3D Scanning technology, photogrammetry and automated inspection solutions for accurate & fast industrial non-contact 3D measurements. 3D inspection is now just a click away!

InspecVision offers the world’s first 3D inspection system that can measure surfaces & edges in 3D. Opti-Scan 3D uses a high speed, high resolution industrial camera and an LED DLP projector to scan the surfaces of an object.Our skilled engineers use CAD design to develop your concepts or drawings to the production stage and use 3D scanning to measure and reverse engineer existing parts so we can manufacture identical products.

3D scanning the sheet metal part with FreeScan Combo The blue laser-equipped FreeScan Combo allows Eurecat to acquire data directly from reflective sheet metal parts, saving them a great deal of time.With 30 years of successful 3D scanning projects under our belts, Laser Design can scan everything from tiny components to vehicles and even entire buildings. We provide customers with unparalleled technology and expertise, both on . The 2D scanner can quickly measure or reverse-engineer flat parts manufactured on laser, plasma or waterjet cutting systems, as well as punched and some stamped parts. .

After using 3D laser scanning for sheet metal inspection (SHINING 3D's FreeScan Combo laser 3D scanner), Eurecat overcame the challenge of quality control and improved digitization efficiency by more than 5 times.Get to know the ATOS Q with ScanBox, an automated solution for scanning and analyzing sheet metal parts. Request your live demo!

3D laser scanning offers tremendous time savings and cost benefits for the metal fabricating and sheet metal forming industry. Most importantly, it provides the ability to reverse engineer and inspect complex parts, assemblies and tooling to a higher level of accuracy and in a shorter period of time than with other methods.Manufacture your molded plastic parts with the ease and efficiency 3D scanning provides. Get it right the first time – and every time after – with high-precision inspection of sheet metal stamping. Create and cast complex shapes with high resolution and accuracy while equipping yourself with ideal 3D measurement tools for evaluation.Capture 3D the leader in 3D Scanning technology, photogrammetry and automated inspection solutions for accurate & fast industrial non-contact 3D measurements. 3D inspection is now just a click away!

InspecVision offers the world’s first 3D inspection system that can measure surfaces & edges in 3D. Opti-Scan 3D uses a high speed, high resolution industrial camera and an LED DLP projector to scan the surfaces of an object.Our skilled engineers use CAD design to develop your concepts or drawings to the production stage and use 3D scanning to measure and reverse engineer existing parts so we can manufacture identical products. 3D scanning the sheet metal part with FreeScan Combo The blue laser-equipped FreeScan Combo allows Eurecat to acquire data directly from reflective sheet metal parts, saving them a great deal of time.

With 30 years of successful 3D scanning projects under our belts, Laser Design can scan everything from tiny components to vehicles and even entire buildings. We provide customers with unparalleled technology and expertise, both on-site and in our lab. The 2D scanner can quickly measure or reverse-engineer flat parts manufactured on laser, plasma or waterjet cutting systems, as well as punched and some stamped parts. The Opti-Scan 3D uses a high-speed, high-resolution industrial camera and an LED DLP projector to scan the surfaces of an object. After using 3D laser scanning for sheet metal inspection (SHINING 3D's FreeScan Combo laser 3D scanner), Eurecat overcame the challenge of quality control and improved digitization efficiency by more than 5 times.Get to know the ATOS Q with ScanBox, an automated solution for scanning and analyzing sheet metal parts. Request your live demo!

3D laser scanning offers tremendous time savings and cost benefits for the metal fabricating and sheet metal forming industry. Most importantly, it provides the ability to reverse engineer and inspect complex parts, assemblies and tooling to a higher level of accuracy and in a shorter period of time than with other methods.

Manufacture your molded plastic parts with the ease and efficiency 3D scanning provides. Get it right the first time – and every time after – with high-precision inspection of sheet metal stamping. Create and cast complex shapes with high resolution and accuracy while equipping yourself with ideal 3D measurement tools for evaluation.Capture 3D the leader in 3D Scanning technology, photogrammetry and automated inspection solutions for accurate & fast industrial non-contact 3D measurements. 3D inspection is now just a click away!

InspecVision offers the world’s first 3D inspection system that can measure surfaces & edges in 3D. Opti-Scan 3D uses a high speed, high resolution industrial camera and an LED DLP projector to scan the surfaces of an object.Our skilled engineers use CAD design to develop your concepts or drawings to the production stage and use 3D scanning to measure and reverse engineer existing parts so we can manufacture identical products. 3D scanning the sheet metal part with FreeScan Combo The blue laser-equipped FreeScan Combo allows Eurecat to acquire data directly from reflective sheet metal parts, saving them a great deal of time.

industrial 3d scanner

With 30 years of successful 3D scanning projects under our belts, Laser Design can scan everything from tiny components to vehicles and even entire buildings. We provide customers with unparalleled technology and expertise, both on-site and in our lab. The 2D scanner can quickly measure or reverse-engineer flat parts manufactured on laser, plasma or waterjet cutting systems, as well as punched and some stamped parts. The Opti-Scan 3D uses a high-speed, high-resolution industrial camera and an LED DLP projector to scan the surfaces of an object.

twitter facebook linkedin youtube blog ul 514a metallic outlet boxes

tv junction box

Like the fact that some houses, particularly in the northeast, have a five-pointed decorative star hanging on the exterior. It’s been cited as being indicative of everything from religion to a.

3d scan sheet metal parts|3d scanning inspection solutions