sheet metal offset layout Pattern making for a round to round transition piece with an offset top and bottom. generally used in sheet metal fabrication for HVAC, food processing, etc.. Welding and metal fabrication are indispensable processes in the metalworking industry, each with its unique functions and challenges. Welding focuses on joining metals, while fabrication involves transforming raw materials into finished products.When deciding between a steel sheet and a steel plate, consider thickness as the main difference. Steel Sheets: Typically thinner, from 0.5 mm .

0 · offset sheet metal patterns

1 · offset bends sheet metal

2 · how to offset sheet metal

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

In this video I'll detail how to make an offset in sheet metal so you can overlap 2 panels together. I'll show how to use your hammer and dollies and also how to use a set of .

Learn how to create sheet metal fabricated parts with our free online tutorials. Sheet Metal Part Design for Manufacturing Tip OFFSETS. Offset height tolerance is +/- 0.012 in. top of sheet / top of form. The ideal offset radius is 0.030 in. Approved Sheet Metal can offer non-standard offsets to parts, but . Pattern making for a round to round transition piece with an offset top and bottom. generally used in sheet metal fabrication for HVAC, food processing, etc.. Our Transitional elbow will be offset from one side only. Here you will layout a 90 Deg. elbow 8/12 to 8/10 keeping one side straight. Draw your flat side pattern and bisect the heel and throat curves, establishing points 3 & 6.

Embosses and Offsets – Emboss and offset dimensions should be to the same side of the material unless the overall height is critical. Only the truly critical dimensions should be .Drop Ogee Offset. The layout for a drop ogre is actually no different than a flat one, with the exception of the length of the cheek. For the drop cheek, because it sits on a slope, the length .

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a . Learn how to layout simple transitions. This tutorial will show you how to layout a 14/10 to 14/8 transition with the bottom flat and total length will be 12". Above, The first thing you need to do is cut a piece of steel 12" wide and .

Learn the basics of sheet metal layout including different seams, techniques and tricks. This video also includes the patterns and layout methods for creati.

Now that you have the bottom layout done, you need to determine the sides and you know that 1 side is 10" x 14"( 14" being the bottom and 10" being the sides)so make a mark 10" from line (A) to line (C). Do this on both .Use the elbow rule (# of pcs × 2 − 2) to find the number of gores.For our example, it is 4 × 2 − 2 = 6.Each end piece is made up of 1 gore and each middle piece is made up of two gores.; Use the angle of the elbow divided by the number of gores to find the miter angle. In our case, 90° ÷ 6 = 15°. Now that we know the miter angle is 15°, we can use an end gore and lay it out similar .Pattern Development: Sheet Metal Level 1. Triangulation. 26 Off-Centre Square to Round The only difference with this fitting is a few more element line lengths than an on-centre, the process is exactly the same. Draw a full plan view complete with all element lines and labeling. Choose a line of symmetry to place the seam so you only need to .

Insulation Sheet Metal Layouts. Beginner Patterns. Tee. Equal Tee is the same size diameter pipe going into another same size pipe in a horizontal or vertical position. It’s the most common pattern used on a daily basis in the field. . Learning the tee can make it easier to also help layout other patterns with only a few more extra steps . Tutorials on Sheet Metal Fabrication. How to develop a Square to Round. Sheet Metal Fabrication Tutorials. Written on 21 December 2008. . Take a look at how we got started, before you can begin to layout your pattern you have to find all your true lengths. The only way you can see a true length line is perpendicular to its plane, the best way .Sheet metal parts are unique because they use common flat stock materials. The following design guide tips will often describe distances in material thickness, or MT, for relative measurements. Flat cut sheet parts, such as flat brackets, can be cut thicker (above ¼”) using plasma Figure 2 shows the layout for the two-piece transition shown in Figure 1. The finished fitting is 14 inches long, but the bottom piece is longer than this. . More often, transitions are made in four pieces in order to save both time and sheet metal. Figure 3 shows the plan and elevation of a typical four-piece transition. Each side of this .

Cone Calculator is helpful for Generating Flat Pattern Layout or Fabrication Layout of all types of cones. This Calculator gives a complete solution to all types of Cones Fabrication Layout. You Can save the Cost of Material by using this calculator. You can Save Time on your Fabrication Layouting process.Sheet metal offset formulas Sheet metal offset layout Square to round duct fittings layout Step by step offsets ductwork Straight between 45 degree elbows rectangle duct offset formulas Types of rectangular offset ducts What is the formula for a 45 degree offset in ductboard?Development Cord Length has calculated by this calculator and Denoted By X1 and X2. This development Angle is used to layout cone fabrication layout markings or Flat Pattern Markings. Refer to Standard Image for understanding these dimensions at Output sections. What are Types of Cone Flat Pattern Layout Available with this Cone CalculatorView and Download Calculated Industries Sheet Metal/HVAC Pro Calc user manual online. . 56 Using Law of Cosines and Pythagorean Theorem to Calculate Offset, Length, and Angle ...58 Sheet Metal Panels for an Irregular . 91 Irregular Hip/Valley and Jack Rafters — Descending, with On-Center Spacing Maintained ...92 STAIR LAYOUT EXAMPLES .

Offset Square to Round - Video Metal Reducing 90s - Video. All of the properties on this page are owned by the the Insulation Industry International Apprentice and Training Fund. International Association of Heat and Frost Insulators and Allied Workers. 9602 Martin Luther King Jr. Hwy. Lanham, MD 20706Draw an elevation view of the flat radius throat radius heel (RTRH) cheek.; Bisect the heel and throat. Label the elevation view, starting from A-B and ending with E-F.; Draw in element lines connecting 4 triangles as shown.; At each point, we want to sub-label with the amount of drop at that point. So both A and B are 0%, C and D are 50% of the drop and E and F are the 100% of .

Layout Drafting & Pattern Making for Insulators Page 2 Preface This book has been prepared as a text for use in Heat and Frost Insulator apprenticeship classes. It explains basic methods of drawing patterns for developing sheet metal and other types of protective covers commonly produced for wrap over insulation. The book does not attempt to teachThe EASTWOOD VERSA-BEND 20" OFFSET SHEET METAL BRAKE is a precision engineered metal working tool designed to produce both standard variable length bends as well as accurate ½" offset bends up to 90° in mild, 20 gauge sheet steel and 18 gauge aluminum in widths up to 20". Also capable of creating bends in 18 gauge steel in widths less than 12”. The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. As illustrated in the accompanying figure, if the bending height is too low, the . Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations. This advanced calculator provides key insights into: Unfolded flat size: The total length of the sheet metal when flattened

Sheet Metal Cone Calculator. View the Cone Instructions below to learn how to manually layout the flat pattern for a truncated cone in single or multiple gore sections. It allows you to determine either the size of raw material needed or the number .

offset sheet metal patterns

#sheetmetal #ductwork #hvac #ventilationGet Offset Fittings from Sheet Metal Connectors for your application. Our fittings are available with or without duct sealant. Skip to content. Sheet Metal Connectors, Inc. – More Than Just Great Connections; Our Projects; FAQs; Phone: 1-800-328-1966; Products. Product Catalogs;

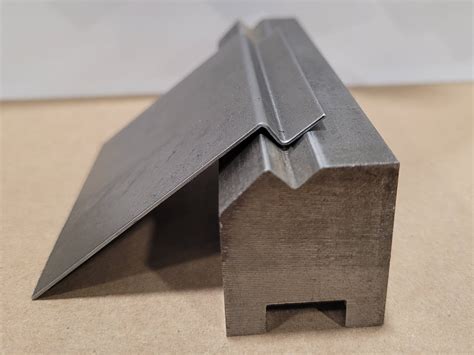

Make sure the fitting is sized correctly. Remember some of the sizing rules for y-branches: the crotch height must be ¾ of the base diameter (or 1.5x the radius), the small openings must equal the large- A2 + B2 = C2 can be used to size the fitting correctly Draw a complete elevation view of 1 side of the fitting. The second side would be traced or a second pattern would be developed .Offset tooling allows two v bends to be formed closer together than regular Press Brake Dies would allow. This creates a z shaped profile in the sheet metal. This type of bend is also commonly referred to as a jog. The two basic forms of offset tooling are .When developing sheet-metal patterns, ensure you add sufficient material to the base dimensions to make the seams. Several types of seams used to join sheet-metal sections are discussed in this section. There are three types of lap seams: the PLAIN LAP seam, the OFFSET LAP seam, and the CORNER LAP seam (fig. 2-66).

Formulas: Bend Allowance (BA) – The amount of added to the sum of the two leg lengths to obtain the flat pattern length. Bend Deduction (BD) – The amount removed from the sum of the two flange lengths to obtain a flat pattern. Material Thickness (MT) – The gauge of the material in decimal form. Bend Angle (B<) – The inside angle between the two legs or flanges of a bend.

Tutorials on Sheet Metal Fabrication. 90 Degree transition elbow. Sheet Metal Fabrication Tutorials. . We know in the flat pattern where our radius pivot point is, however when we layout the pattern for the offset cheek we need to establish the pivot point for the heel and the throat. We will be making the offset much like three hinged triangles.Transition Calculator is very helpful in sheet metal fabrication, process equipment fabrication and other types equipment fabrication industry where transion shapes are used. . Flat Pattern Layout Accuracy is depends upon no. of development lines its accuray is increase if increase no. of development lines but it consumes more time for layout .

aquaman superhero vintage metal lunch boxes with thermos for sale

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, .

sheet metal offset layout|offset sheet metal patterns