sheet metal burr standard Example: If you work in the automotive industry, the burr standard cannot be generalised between Bumper and Mounting bracket of Engine, even though both of them are . $269.95

0 · maximum burr allowance

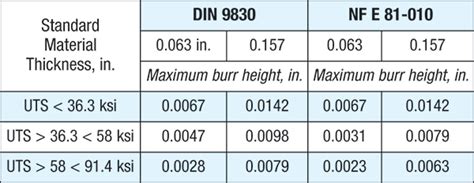

1 · burr limit for sheet metal

2 · burr allowance chart

3 · acceptable burr height for metal

4 · acceptable burr height

Find company research, competitor information, contact details & financial data for WILEY METAL FABRICATING INC of Marion, IN. Get the latest business insights from Dun & Bradstreet.

The maximum acceptable burr height for a metal stamping is equal to 10 percent of sheetmetal thickness. The above statement would be true if all stampings were produced from low-carbon steel less than 0.050 in. thick, .

ISO 7755-1:2013 specifies the common characteristics of hardmetal burrs of various styles, in solid design or with brazed shank. Example: If you work in the automotive industry, the burr standard cannot be generalised between Bumper and Mounting bracket of Engine, even though both of them are .

Burr allowance is generally 10% of the thickness of the sheet material. To minimize instances and severity of burrs, avoid sharp corners and complex cutouts when possible.

Counter sinks – A counter sink can be put in sheet metal by both machining and/or punching. Each of these methods give the finished part different characteristics. The cross sections of . A frequently quoted standard is BS EN ISO 8442.5:2005, which is similar to the National Institute of Justice specification NIJ Standard-0115.00. These standards can be used to test the sharpness of objects that are . Using a machine to remove burrs from and put a surface finish on sheet metal and plate, also known as deburring and graining, is more complicated than it seems. The factors that go into selecting and setting up a deburring and graining machine are almost as numerous as the factors that cause burrs in the first place. Some of the important factors you have to consider .INSTRUCTION SHEET Identification: INS-033.1 TMA Standard Tolerances Page: 5/17 2.3 Gouging Depth “p” Definition: scourings or kerves of limited depth on the cut surface, generally in the direction of cut thickness Gouging defect 5 Accept: “p” no greater than 5% of thickness and less than 2 mm deep Repair: defect less than 4 mm Defects are filled in by welding followed by .

Burr formation is common sheet metal defect and Burr control / deburring is an important issue for industrialist and engineers. It is produced in all shearing & cutting operations. In sheet metal parts burr is usual but after a specified limit it takes a form of defect. This leads to rework and quality problem of part. Dornfeld reports that one aircraft manufacturer with which he works frequently uses a simple dial indicator mounted on a tripod that rests on sheet metal or plates. As the anvil at the end of the dial rests on top of the burr, it actuates the dial. "If the dial says that the burr is less than the specification, then the part is good," he says.

Many products use sheared sheet metal, yet only one standard, UL 1439, addresses the issue of sheet metal sharpness directly. The other sharpness standards exist to define when products that are supposed to be sharp are sharp enough, or to rate products that are intended to protect users from sharp products.

maximum burr allowance

burr limit for sheet metal

round junction box lowes

By using standard vee-dies, cost savings can be realized through economical set-ups . Critical Dimensions Sheet Metal Forming – Outside dimension should be used unless the inside dimension is critical. - 3 - . leaves an unavoidable “feather edge” burr along the . It produces a burr up near but not above 10% of metal thickness. My young apprentice saw this and asked if it was acceptable do to handling concerns. The owner of the company said that it was within the industry standard of a 10% burr there for is acceptable.1pcs DB1000 Sheet Metal Deburring Tool/(Double Burr) 0-12 Mm Range & N80 Blades. suzhoustar (58) 100% positive; . Free SpeedPAK Standard. See details for shipping. . Industrial Metal Sheets & Flat Stock 12 in Sheet/Flat Stock,

I've had some pretty good luck hand grinding a standard 118 drill into a psuedo brad-point for sheet metal. Pretty much grind it as a flat bottom, but leave a tit in the middle to keep centered. Doesn't last a long time, but it will keep from creating a super burr.DIN 9830 Burr heights on stamped parts - Free download as PDF File (.pdf), Text File (.txt) or read online for free.We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal design guidelines for complex sheet metal parts. . Sheetmetal is available in standard thickness. Manufacturer .

The intent of this specification is to define burr conditions, eliminate judgments and establish accept / reject criteria for parts. 3.0 Conflict Statement 3.1 As there is no standardized specification for deburring and burr classification, this document will represent the J & M Products, Inc. standard 3.2 1pcs DB1000 Sheet Metal Deburring Tool/(Double Burr) 0-12 Mm Range & N80 Blades. treeverdure (2883) 97.8% positive; . US .70 SpeedPAK Standard. See details for shipping. . Industrial Metal Sheets & Flat Stock 12 in Sheet/Flat Stock,

A typical burr formed on a metal component due to the exit of a cutting edge is seen in Figure 3, after /3/. A number of things are clear from this image– there is substantial . strategy due to reduced and more standard burr size and shape. This requires a comprehensive approach to burr prevention and minimization consisting of a number of

The clearances range from about 6% of the sheet material thickness for mild steel up to 16% or even higher as the sheet metal tensile strength exceeds 1400 MPa. A study C-2 compared the tool wear and burr height formation associated with .the burr formation during blanking of metal sheets. This effort will not only help to optimize the blanking process, but also to increase the product quality and reduce the cost of production. Typical pattern of shear strain field evolved at various punch penetrations of sheet metal blanking is being studied. Metal Burr Removal: Metalworking is an age-old craft that has evolved significantly with advancements in technology and machinery. . 4.3.1 Deburring Sheet Metal Edges. . The metalworking industry requires a variety .

DB1000 Sheet Metal Deburring Tool (Double Burr) 0-12mm Range Practical Replace. fashion-king87 (4694) 97.6% positive; . Free SpeedPAK Standard. See details for shipping. . Metal Sheet Diamond Industrial Metal Sheets & Flat Stock,Standard Sheet Metal is an industry leader in architectural, commercial, and industrial metal fabrication & manufacturing custom steel components. Standard Sheet Metal Toggle NavigationThe clearances range from about 6% of the sheet material thickness for mild steel up to 16% or even higher as the sheet metal tensile strength exceeds 1400 MPa. A study C-2 compared the tool wear and burr height formation associated with .combination snips, standard snips or aviation snips (easiest) . A burr is a(n) _____. decorative. Beading is added to the sheet metal object for added rigidity or for _____ purposes. sheet metal. Seams are used to join _____ sections. soldered, riveted or screwed. Name three methods that can be used to fasten metal sheets. .

A New Approach for the Production of Burr-Free Sheet Metal Components Having Significantly Increased Residual Formability July 2021 DOI: 10.1007/978-3-030-75381-8_232

Sheet metal blanking is an industrial process widely used in automotive, electronics, aerospace and several other industrial applications. Burrs are the hard and sharp-raised edges formed at the . I've used backing when drilling flat sheets of metal. But a metal garbage can has basically no flat surfaces - everything is ridges. . the helix is what pulls on the thin sheet and can leave a burr even with a backer by lifting the whole sheet. You would also notice with a standard jobber 2 flute drill that the hole is not round. That would .

burr measurement of metal parts which were processed by sheet presswork. The part is the metal ’cap’ at the end of the neon tube (Fig. 1). The part goes through different steps; punching, bending, deep-drawing processes, until it gets its final shape. The following subtasks were defined: researching the phenomenon of burr formation, Custom sheet metal shearing. In custom sheet meta l shearing, several components are formed from metal sheets and can be utilized to produce different items. Accuracy is essential, and in this case, the shearing process efficiently provides that. Moreover, it does not require excessive heat and does not produce much waste, so many sheet metal .

Download scientific diagram | Clearance-burr height relation for 1 mm sheet thickness from publication: The Relationship of Burr Height and Blanking Force with Clearance in the Blanking Process of .

round metal box

burr allowance chart

Appraisal requirements for FHA mortgage loans are found in HUD 40001., and include guidelines for electrical systems, plumbing, paint, and also .

sheet metal burr standard|burr allowance chart