how to bend sheet metal without a bender Here's a cool trick for bending thin-gauge sheet metal without needing a brake. On our farm, we’ve got an old outbuilding and a dream to build a party barn. Progress is coming along nicely. We’re looking forward to having a gathering . So yes, you’ll need some kind of junction box there. If the existing junction box for some reason sticks out past the joist at a depth greater than the finish ceiling material (usually 1/2” drywall) then yes you might want to replace or adjust it to be flush with the bottom of the joist.

0 · sheet metal bending dies

1 · sheet metal bending chart

2 · sheet metal bending by hand

3 · how to bend metal professionally

4 · folding sheet metal at home

5 · bending operation in sheet metal

6 · bending 16 gauge sheet metal

7 · bend sheet metal without brake

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

Caliber8 Tools & DIY. 27.9K subscribers. Subscribed. 1.3K. 109K views 3 years ago #sheetmetals #metalbender #Caliber8Tools. Learn how to use a straight handle hand seamer to bend sheet.

How To Bend Sheet Metal Without A Brake: How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.

sheet metal bending dies

sheet metal bending chart

Simple sheet metal bender using a hand roller, clamps and plywood.Music: Monkeys Spinning Monkeys by Kevin Macleod.Here's a cool trick for bending thin-gauge sheet metal without needing a brake. On our farm, we’ve got an old outbuilding and a dream to build a party barn. Progress is coming along nicely. We’re looking forward to having a gathering . Bend sheet metal without a brake. The bend won’t be quite as sharp, but suitable bends can be made for many construction projects without using a brake. This video will show you how to do it, and hopefully save you .Bending long pieces of alu sheet without a break. I have an old piece of 80cm sheet that I need to bend into a chassis for a projects, 1.5mm thick if I recall correctly. I don't own a break myself so if I don't get access to one I'll have to .

When working with sheet metal one particularly useful piece of equipment is the brake. A brake is a device that allows you to bend a piece of sheet metal at a particular angle. Metal shops have brakes mounted at different angles with automated braking arms, however it is possible to bend sheet metal at home without the use of a brake. This doesn’t just work with thin sheet metal. You can use this method to bend material that would make a sheet metal bending brake cry. So what is this 2-step diy bending process that can do the job of a press brake? Here’s the secret: Step 1 – Make relief cuts in your part along the line you want to bend. Step 2 – Bend. That’s it, no . Sheet Metal Benders Sheet metal benders have become an essential tool to the professional tinsmith. These types of tools act as portable brakes and allow the worker to bend metal onsite without having to rely on a heavy brake in the back of the truck or in the shop. Some benders are especially adept at making 90° bends for flashing, while .By lining the routed grove up with the angle along the table edge and the end of the "tool", you can focus the bend where you want it. Move slowly along the fold, doing 10 – 20 degree bends at a time. Also, after each bending pass, work along with rubber mallet to sharpen the bend by bashing either side of the bend on the table edge.

A professional bender will usually have a spreadsheet with the die they use for each material. The thicker or more brittle the material is the larger the radius of the bend will be. Also ask them if they use a k-factor to calculate the bend deductions or if .However, for bending metal siding, you want to use metal, since wood is just not hard enough to get the best and most precise bend in the siding material. Prepping Vinyl As we mentioned earlier in the article, if vinyl is cold, it is much more susceptible to . You may also want to use a steel block for added support when bending thicker pieces of brass sheet. Bending Basics. Brass is an incredibly strong material that can be difficult to work with if it isn’t properly prepared. To ensure that your piece of the brass sheet will bend without fracturing or cracking, it is important to ‘anneal’ it .

`The information provided on this website is for educational and informational purposes only and solely as a self-help tool for your own use. It is the responsibility of the viewer to First read the Technical Data Sheet, Material Safety Data Sheet, and any other instructions for each product, tool, or equipment used and to follow the safety .Here are a few things to keep in mind when bending the aluminum sheet to avoid breakage: Make sure that you do not bend the sheet too sharply. Avoid creasing the sheet. Avoid over-bending the alloy or making a tighter bend beyond the minimum bend radius. A smaller bend may crack or break along the bend line. Final Thoughts. Bending aluminum can .Aluminum fascia or metal sheets need to be bent at a certain angle to be used on the roof. And a brake can do that easily for you. . Depending on the thickness you might have to use one or both of your hands to bend an aluminum sheet. And if you place it just correctly and hold it with a tool, you will be able to bend it better with your .

In this episode we build a metal brake for bending steel or aluminum. We need to make the aluminum battery box in the 1973 Datsun 240Z so this will help form. In this how to I give an easy example using simple shop tools and materials to bend some thin aluminum sheet without the added expense of an expensive metal . Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum . Otherwise roll bending and tube bending are also option to do the sheet metal bending without using metal brake and accessories. 6 Key Tips of Bend Metal Sheet . Tips to bend metal sheet are having proper metal bending .

sheet metal bending by hand

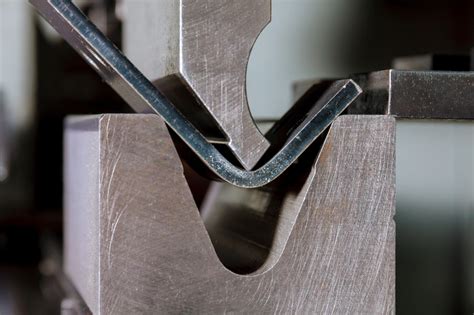

Defining Sheet Metal Bending. Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with. The bending process alters the sheet metal’s shape without changing its . Position them strategically on the metal roofing sheet, ensuring it won’t shift during the bending process. . Both professional assistance and alternative options offer advantages, allowing you to bend metal roofing without causing damage and achieve the desired results. Whichever route you choose, be it seeking professional help or . Metal Reborn is now live online!! Here’s the link below!! ⬇️⬇️⬇️⬇️⬇️http://www.metalreborn.comOn this episode of Make It Kustom, I show you how . Learn how to make rounded bends with a sheet metal brake in this informative video tutorial.

Benefits of Bending 16 Gauge Sheet Metal Bending 16 gauge sheet metal has several benefits. For instance, it can be used to make various products such as HVAC ducts, electrical enclosures, and automotive parts. Bending sheet metal also allows you to create clean and accurate bends that enhance the aesthetic appeal of the finished product. Now that you’re prepared, let’s explore some alternative methods for bending conduit without a bender in the next section. When bending conduit without a bender, use a spring bender or fill the conduit with sand before bending to prevent kinking. Bend slowly and carefully to avoid damaging the conduit. Using Alternative Methods for Bending .

Bending sheet metal without a brake is possible; however, other techniques are available with a focus on precision. For example, one may make use of a workbench edge accompanied by clamps in order to secure the metal. One end of the bench acts as the pivot, allowing the user to push a dowel rod, whether wood or metal, over and along the bend .

Showing how I bend steel plate without using a brakeSimple And Easy Techniques For Bending Metal Sheet into A Circle / Useful ideas For Bend Sheet Metal Easily Hi Friends. NAMASTE. Welcome To The.At Woodard Fab, we are committed to providing value-driven form sheet metal bending tools that ease metal bending tasks in the metal fabrication industry. Constructed utilizing advanced technologies, our range of benders produce accurate and neat bends on sheet metal without damaging the work-piece.

how to bend metal professionally

folding sheet metal at home

bending operation in sheet metal

bending 16 gauge sheet metal

Cotton is an insulating fabric, but rayon is known as a non-insulting fabric. Rayon is a fabric that can be used in humid climates, whereas cotton is a better choice in warm climates. Rayon gets weak when wet. The cotton fabric is stronger when it's wet. The cost of cotton is higher than rayon.

how to bend sheet metal without a bender|folding sheet metal at home