benefit cnc machining CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry. It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends.

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.

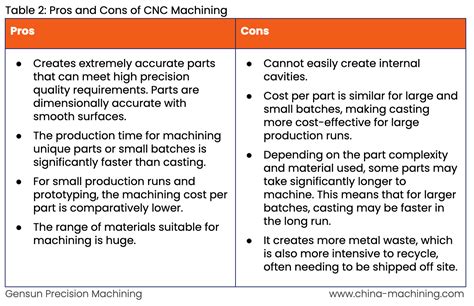

0 · pros and cons of machining

1 · disadvantages of cnc milling

2 · disadvantages of cnc

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machining advantages and disadvantages

6 · cnc machine pros and cons

7 · cnc advantages and disadvantages

Standard measurements apply to both sheet sizes and thicknesses. While achieving large sheet sizes have a few workarounds through welding, you cannot really look past the thickness tables. Knowing standard sheet sizes helps you with optimising your part layouts.

pros and cons of machining

This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, . CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique .

In the electronics industry, CNC machining helps to create PCBs, housings, jigs, fixtures, and other components. The military sector frequently turns to CNC machining for the prototyping of rugged and reliable parts. The .

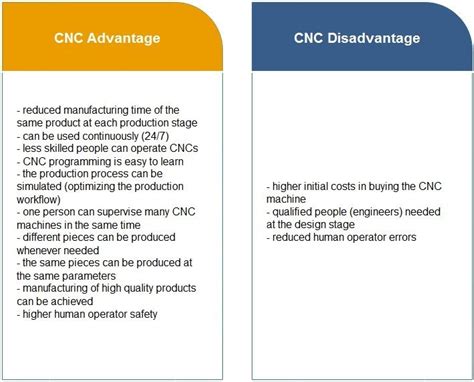

do metal bread boxes work

In this article, we’ll explore the many benefits of CNC machining and milling. These benefits include their impact on production volume, labor needs and material use. We’ll also discuss downsides like the high initial investment and . Discover the key benefits of CNC machining, from precision and efficiency to cost savings. Learn how it’s revolutionizing industries like aerospace, defense, and automotive.CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry. It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends. This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, making it ideal for high-precision and large-volume production.

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries. In the electronics industry, CNC machining helps to create PCBs, housings, jigs, fixtures, and other components. The military sector frequently turns to CNC machining for the prototyping of rugged and reliable parts. The intention of the machining is to allow the parts to withstand wear and tear with minimal upkeep.

In this article, we’ll explore the many benefits of CNC machining and milling. These benefits include their impact on production volume, labor needs and material use. We’ll also discuss downsides like the high initial investment and material restrictions. Discover the key benefits of CNC machining, from precision and efficiency to cost savings. Learn how it’s revolutionizing industries like aerospace, defense, and automotive.

CNC machining is a form of manufacturing that uses computer-controlled machine tools to create parts and products. The main advantages of CNC machining over traditional methods are greater accuracy, more precise control, and higher efficiency.CNC machining emerges as a beacon in this journey, offering unparalleled advantages that have transformed production processes across industries. Before we delve into the specifics, let’s set the stage by understanding why CNC machining is .CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal. 1. Precision and Consistency. CNC milling machines offer exceptional precision. One of the primary benefits of CNC machining is its exceptional precision and accuracy. CNC (Computer Numerical Control) machines are capable of producing parts with incredibly tight tolerances, ensuring that each piece meets the exact specifications of the design.

CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry. It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends. This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, making it ideal for high-precision and large-volume production.

CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes. It offers many unique benefits that make it a valuable technology for a wide range of industries.

In the electronics industry, CNC machining helps to create PCBs, housings, jigs, fixtures, and other components. The military sector frequently turns to CNC machining for the prototyping of rugged and reliable parts. The intention of the machining is to allow the parts to withstand wear and tear with minimal upkeep.

In this article, we’ll explore the many benefits of CNC machining and milling. These benefits include their impact on production volume, labor needs and material use. We’ll also discuss downsides like the high initial investment and material restrictions. Discover the key benefits of CNC machining, from precision and efficiency to cost savings. Learn how it’s revolutionizing industries like aerospace, defense, and automotive. CNC machining is a form of manufacturing that uses computer-controlled machine tools to create parts and products. The main advantages of CNC machining over traditional methods are greater accuracy, more precise control, and higher efficiency.CNC machining emerges as a beacon in this journey, offering unparalleled advantages that have transformed production processes across industries. Before we delve into the specifics, let’s set the stage by understanding why CNC machining is .

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal. 1. Precision and Consistency. CNC milling machines offer exceptional precision.

do metal box springs ruin the mattress

Have you ever noticed a star adorning the exterior of a house and wondered about its significance? These stars are seldom the same, often seen in various colors, sizes, and materials — they are not just decorative elements; they carry a wealth of history and meaning.

benefit cnc machining|disadvantages of cnc