brushed cnc parts XEBEC has the deburring & finishing tools for your unique application. Read about . Types of Sheet Metal. There are six major types of sheet metal material, each with its own unique advantages: Aluminum ; Alloy Steel; Carbon Steel; Tool steel ; Galvanized steel ; Stainless .

0 · xebec brush surface end type

1 · deburring tool for cnc machines

2 · deburring brush for cnc machine

3 · cnc polishing tool

4 · cnc dust boot brush

5 · cnc deburring brushes for aluminum

6 · cnc brush deburring

7 · abrasive brush for deburring

CNC machines are computer-controlled machines that automate manufacturing processes and increase productivity. There are several main types of CNC machines, including milling machines, plasma-cutting machines, lathe machines, laser-cutting machines, and electric discharge machines.

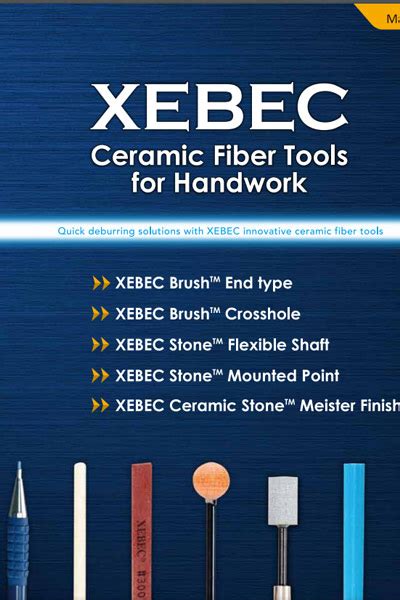

Modernize machining with our innovative deburring & surface finishing brushes and stones. These ceramic fiber cutting tools belong in your CNC tool holder.Due to the unique design of XEBEC products, we have achieved optimal .Our customer was manually deburring the two parts shown in the charts. By .XEBEC has the deburring & finishing tools for your unique application. Read about .

Deburring Technologies, LLC is the North American partner for Xebec® .

For simultaneous cutter mark removal, deburring, surface finishing and edges. . Discover the ins and outs of achieving a professional "Brush" finish for your CNC machined parts. Learn the basics of surface finishes and elevate your metal components.

The art of transforming ordinary metal into a masterpiece involves a multitude of techniques, and one of the most popular is the brushed metal finish. This finish type, known for . By selecting the right brush, controlling brushing direction, adjusting speed and pressure, and regularly maintaining brushes, a uniform brushed surface effect on custom .

xebec brush surface end type

Modernize machining with our innovative deburring & surface finishing brushes and stones. These ceramic fiber cutting tools belong in your CNC tool holder. Discover the ins and outs of achieving a professional "Brush" finish for your CNC machined parts. Learn the basics of surface finishes and elevate your metal components.The deburring process is crucial for manufacturing clean parts. The deburring brush for CNC works by removing material from the part. It is used to make small imperfections on parts disappear so that finished parts will be more saleable. The operator maneuvers the brush in .

The art of transforming ordinary metal into a masterpiece involves a multitude of techniques, and one of the most popular is the brushed metal finish. This finish type, known for its fine lines and distinctive texture, can turn a standard component into a work of art.

By selecting the right brush, controlling brushing direction, adjusting speed and pressure, and regularly maintaining brushes, a uniform brushed surface effect on custom-made parts can be achieved. Understanding the similarities and differences between brushing and other surface finishings, as well as its application on different materials .

The process is used to reduce surface roughness on parts that must mate or seal beyond the capabilities of machining operations. Brushing finish exists in different forms and modified forms that suit a wide range of application flexibilities. A brushed finish allows the creation of fine parallel lines on the surface of machined parts. The finish allows easy removal and prevents the accumulation of dirt, rust, slags, grime, film, and other contaminants. Brush Finish Processing: Utilize abrasive belts or wheels of varying materials, grit sizes, shapes, and hardness to mechanically apply the brush finish. Depending on requirements, techniques such as unidirectional brushing, cross-brushing, . Brushed finishing is a metal surface treatment that creates a directional and smooth texture. This process uses abrasive materials or wire brushes to abrade the metal surface which results in parallel and fine lines.

Brushing Surface Finish is one method that has endured the test of time and remains a popular choice. This technique uses abrasive brushes or pads strategically to create a textured surface that improves both the visual appeal and functioning of diverse materials.Modernize machining with our innovative deburring & surface finishing brushes and stones. These ceramic fiber cutting tools belong in your CNC tool holder. Discover the ins and outs of achieving a professional "Brush" finish for your CNC machined parts. Learn the basics of surface finishes and elevate your metal components.The deburring process is crucial for manufacturing clean parts. The deburring brush for CNC works by removing material from the part. It is used to make small imperfections on parts disappear so that finished parts will be more saleable. The operator maneuvers the brush in .

The art of transforming ordinary metal into a masterpiece involves a multitude of techniques, and one of the most popular is the brushed metal finish. This finish type, known for its fine lines and distinctive texture, can turn a standard component into a work of art. By selecting the right brush, controlling brushing direction, adjusting speed and pressure, and regularly maintaining brushes, a uniform brushed surface effect on custom-made parts can be achieved. Understanding the similarities and differences between brushing and other surface finishings, as well as its application on different materials .The process is used to reduce surface roughness on parts that must mate or seal beyond the capabilities of machining operations. Brushing finish exists in different forms and modified forms that suit a wide range of application flexibilities. A brushed finish allows the creation of fine parallel lines on the surface of machined parts. The finish allows easy removal and prevents the accumulation of dirt, rust, slags, grime, film, and other contaminants.

Brush Finish Processing: Utilize abrasive belts or wheels of varying materials, grit sizes, shapes, and hardness to mechanically apply the brush finish. Depending on requirements, techniques such as unidirectional brushing, cross-brushing, .

Brushed finishing is a metal surface treatment that creates a directional and smooth texture. This process uses abrasive materials or wire brushes to abrade the metal surface which results in parallel and fine lines.

tiffin box steel price

through the wall electrical box

There are five common types of sheet metal joints that are extremely common across the industry, all with varying uses and advantages.

brushed cnc parts|deburring brush for cnc machine