box distribution power car Automotive primary power distribution: Providing supply, control, . Spanners are generally used for tightening or loosening various fasteners.These are designed with drop-forge steel or carbon steel. But in welding, a double-ended spanner is used for tightening and opening the nuts of the welding apparatus and job. #2 Hammer

0 · wiring junction boxes for automotive

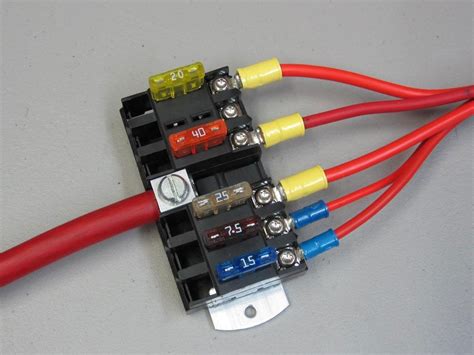

1 · power distribution center automotive

2 · clamp 15 and 30 automotive

3 · automotive terminal block with cover

4 · automotive power distribution terminal blocks

5 · automotive power distribution blocks

6 · 48v to 12v module

7 · 12v power distribution module

Learn about different types of weld-on hinges and follow our step-by-step guide on how to weld hinges onto gates for secure, durable installations.

The automotive power distribution system is built on three main elements - the primary power distribution, the secondary power distribution and the electronic control units (ECUs). The .Automotive primary power distribution: Providing supply, control, .

The design of power distribution systems plays a key role in automotive power management since it dictates how electrical energy is distributed to different parts and subsystems inside a car. To meet the many and frequently intricate needs .Automotive primary power distribution: Providing supply, control, communication, sense, and actuation functions. Advanced driver assistance systems (ADAS) and automated drive (AD) functions in modern cars require high availability and fail .A PDM replaces all these fuses and relays with a single discrete box, and all this power distribution is now taken care of by solid-state switching, as opposed to traditional mechanical switching relays. What does a PDM actually do for us .Secondary power distribution is supplied from primary power distribution and controls the power supply to electronic control units (ECUs) for the main car functions and directly supplies major loads. The classical solution is based on .

Today, almost all manufacturers use relays and fuses in the junction box. The trend from 2020 to 2025 or even to 2030 will be to replace all the mechanical pieces in the car distribution box. The last box 6) is engine .TE's power distribution boxes are flexible, cost-effective, and suitable for complex automotive and heavy-duty vehicle networks. Ask about our standalone modules and integrated solutions. The home of vehicle power distribution, the “fuse box”, has undergone some significant changes as a result of these efforts. We’ll take a look at what’s new in the fuse box as well as some diagnostic approaches for some .

Whichever power distribution or control product you need - regardless of your automotive segment—we are ready and able to help. Yazaki has the expertise and resources to optimize . The power supply for the production halls in a car manufacturing plant is distributed by means of medium-voltage load center systems. Every MV load center system is .The automotive power distribution system is built on three main elements - the primary power distribution, the secondary power distribution and the electronic control units (ECUs). The primary power distribution is close to the source, often called the pre-fuse box.

wiring junction boxes for automotive

The design of power distribution systems plays a key role in automotive power management since it dictates how electrical energy is distributed to different parts and subsystems inside a car. To meet the many and frequently intricate needs of contemporary automobile systems, the architecture must be strong, versatile, and adaptive.Automotive primary power distribution: Providing supply, control, communication, sense, and actuation functions. Advanced driver assistance systems (ADAS) and automated drive (AD) functions in modern cars require high availability and fail-operational capabilities.

A PDM replaces all these fuses and relays with a single discrete box, and all this power distribution is now taken care of by solid-state switching, as opposed to traditional mechanical switching relays. What does a PDM actually do for us and why would we want to use one?

Secondary power distribution is supplied from primary power distribution and controls the power supply to electronic control units (ECUs) for the main car functions and directly supplies major loads. The classical solution is based on relay and fuse boxes, but the location is restricted to easily accessible areas to limit labor cost in case of .

Today, almost all manufacturers use relays and fuses in the junction box. The trend from 2020 to 2025 or even to 2030 will be to replace all the mechanical pieces in the car distribution box. The last box 6) is engine management.

TE's power distribution boxes are flexible, cost-effective, and suitable for complex automotive and heavy-duty vehicle networks. Ask about our standalone modules and integrated solutions. The home of vehicle power distribution, the “fuse box”, has undergone some significant changes as a result of these efforts. We’ll take a look at what’s new in the fuse box as well as some diagnostic approaches for some of the problems related to power distribution.Whichever power distribution or control product you need - regardless of your automotive segment—we are ready and able to help. Yazaki has the expertise and resources to optimize power and data delivery in the more capable, feature .

The power supply for the production halls in a car manufacturing plant is distributed by means of medium-voltage load center systems. Every MV load center system is operated in combination with a low-voltage system built from high-current busbars and busbar trunking systems (Figure 2 and 3).The automotive power distribution system is built on three main elements - the primary power distribution, the secondary power distribution and the electronic control units (ECUs). The primary power distribution is close to the source, often called the pre-fuse box.The design of power distribution systems plays a key role in automotive power management since it dictates how electrical energy is distributed to different parts and subsystems inside a car. To meet the many and frequently intricate needs of contemporary automobile systems, the architecture must be strong, versatile, and adaptive.

Automotive primary power distribution: Providing supply, control, communication, sense, and actuation functions. Advanced driver assistance systems (ADAS) and automated drive (AD) functions in modern cars require high availability and fail-operational capabilities.A PDM replaces all these fuses and relays with a single discrete box, and all this power distribution is now taken care of by solid-state switching, as opposed to traditional mechanical switching relays. What does a PDM actually do for us and why would we want to use one?Secondary power distribution is supplied from primary power distribution and controls the power supply to electronic control units (ECUs) for the main car functions and directly supplies major loads. The classical solution is based on relay and fuse boxes, but the location is restricted to easily accessible areas to limit labor cost in case of .

Today, almost all manufacturers use relays and fuses in the junction box. The trend from 2020 to 2025 or even to 2030 will be to replace all the mechanical pieces in the car distribution box. The last box 6) is engine management.TE's power distribution boxes are flexible, cost-effective, and suitable for complex automotive and heavy-duty vehicle networks. Ask about our standalone modules and integrated solutions. The home of vehicle power distribution, the “fuse box”, has undergone some significant changes as a result of these efforts. We’ll take a look at what’s new in the fuse box as well as some diagnostic approaches for some of the problems related to power distribution.

Whichever power distribution or control product you need - regardless of your automotive segment—we are ready and able to help. Yazaki has the expertise and resources to optimize power and data delivery in the more capable, feature .

power distribution center automotive

single gang electrical junction box cover

single gang metal switch box

simple eave box gutter installation detail on metal siding

clamp 15 and 30 automotive

Welding bonds two metal pieces into one unit using heat or pressure. It is a specific step in a larger metalworking process. Key welding methods, like MIG, TIG, and stick welding, suit different project needs. While focused on metals, welders sometimes join plastics and glass, too.

box distribution power car|wiring junction boxes for automotive