+cnc +machining +automotive The automotive industry integrates CNC machining to optimize performance, enhance safety, and reduce production costs. This is especially true now, as electric and hybrid vehicles become the standard.

Long overdue tool box upgrade for me! I've wrestled with the old bent up, small drawers in my old tool box for more than 30 years, I deserve better! I've e.

0 · cnc machining in automotive industry

1 · cnc machine automotive parts

2 · cnc automotive parts

3 · c&c automotive repair

4 · c&c automotive refinishing

5 · c&c auto shop

6 · c&c auto repair

7 · automotive cnc machining

It may be made overseas, probably is, but it is very heavy gauge steel and has roller bearings and I have a lot more money left to buy good tools. A box is a box and if you take care of them they all do the same job, store your tools.

What products are made by CNC machining for automotive industry? One application of CNC machine technology is prototyping. In the automotive industry, CNC machined prototypes can include anything from .

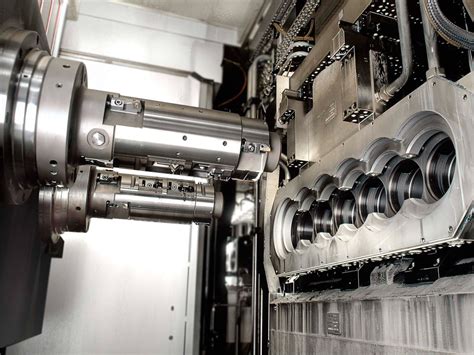

CNC Machining in the automotive industry guarantees repeatability because it is a computer-controlled process. Repeatability is essential to ensure consistency between . CNC Automotive machining is a production method that employs computer-controlled equipment to cut, mold, and automotive parts precisely. Also, this process can make intricate shapes out of materials like plastic or metal.

CNC Machining helps in the automotive industry for both prototyping and production applications. In the latter category, the process offers the benefit of producing high-quality, functional prototypes. The prototypes are then .

The bottom line is that automotive manufacturers need to be pairing their CNC machining with CAM software to stay competitive. The recent supply chain shortages, increasing vehicle sales, and ever-present safety standards make precision and speed of .The automotive industry integrates CNC machining to optimize performance, enhance safety, and reduce production costs. This is especially true now, as electric and hybrid vehicles become the standard. In this article, we discuss the relationship between CNC machining and automotive manufacturing, exploring how this technology has revolutionized the production of car components, enhanced performance, and introduced a .CNC machining enables automotive designers and engineers to unleash their full creative potential. Its ability to transform intricate designs into reality has paved the way for advancements in aerodynamics, weight reduction, vehicle performance, fuel efficiency and safety.

CNC Milling operates with computerized automation, significantly reducing the chances of human error and increasing production speed. This automation is crucial in enhancing efficiency and productivity within the automotive industry, allowing for .Tier 1 manufacturers and their supply chain partners in the automotive industry trust Methods to engineer world-class CNC machining solutions that deliver reduced cycle times, greater precision, and higher overall equipment efficiency to meet the demands of car and truck OEMs.

CNC Machining in 11 Technologies and their Automotive Applications. Through the application of CNC machining, let’s see how CNC technology demonstrates its precision and importance in the automotive industry. (1) CNC turning. CNC turning is a flexible method that is widely used in the auto business to make accurate cylinder parts.

cnc machining in automotive industry

cnc machine automotive parts

14 sheet metal duct tee 28 gauge

AI and machine learning will revolutionize CNC machining in automotive production. Predictive maintenance algorithms will minimize downtime, while dynamic tool path optimization and automated quality control systems will enhance efficiency and product consistency. CNC Automotive machining is a production method that employs computer-controlled equipment to cut, mold, and automotive parts precisely. Also, this process can make intricate shapes out of materials like plastic or metal. CNC Machining helps in the automotive industry for both prototyping and production applications. In the latter category, the process offers the benefit of producing high-quality, functional prototypes. The prototypes are then .

The bottom line is that automotive manufacturers need to be pairing their CNC machining with CAM software to stay competitive. The recent supply chain shortages, increasing vehicle sales, and ever-present safety standards make precision and speed of .The automotive industry integrates CNC machining to optimize performance, enhance safety, and reduce production costs. This is especially true now, as electric and hybrid vehicles become the standard. In this article, we discuss the relationship between CNC machining and automotive manufacturing, exploring how this technology has revolutionized the production of car components, enhanced performance, and introduced a .

CNC machining enables automotive designers and engineers to unleash their full creative potential. Its ability to transform intricate designs into reality has paved the way for advancements in aerodynamics, weight reduction, vehicle performance, fuel efficiency and safety. CNC Milling operates with computerized automation, significantly reducing the chances of human error and increasing production speed. This automation is crucial in enhancing efficiency and productivity within the automotive industry, allowing for .

Tier 1 manufacturers and their supply chain partners in the automotive industry trust Methods to engineer world-class CNC machining solutions that deliver reduced cycle times, greater precision, and higher overall equipment efficiency to meet the demands of car and truck OEMs.

CNC Machining in 11 Technologies and their Automotive Applications. Through the application of CNC machining, let’s see how CNC technology demonstrates its precision and importance in the automotive industry. (1) CNC turning. CNC turning is a flexible method that is widely used in the auto business to make accurate cylinder parts.

14 inch metal enclosure

cnc automotive parts

I put 16 gauge floor panels in the one I'm working on now, with a framework of 3/4" 1/8"-wall square tubing to support it so there aren't any large spans of metal to act like noisy drum heads. It has a real solid feel. In another car, I used 18 gauge for the floor.What gauge of metal are military ammo boxes? Military ammo boxes are typically made from steel that is around 14 gauge, which provides the necessary strength and durability to protect the ammunition inside.

+cnc +machining +automotive|c&c automotive refinishing