cnc lathe machine introduction pdf The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, . DEYUCNC provides Custom Anodized Aluminum Metal CNC Machining Parts Supplier

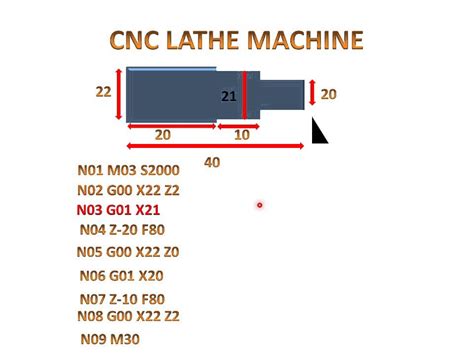

0 · cnc turning program examples PDF

1 · cnc turning machine programming PDF

2 · cnc turning cycle program PDF

3 · cnc programming for dummies PDF

4 · cnc programming PDF free download

5 · cnc machine parts list PDF

6 · cnc machine operation manual PDF

7 · cnc lathe manual PDF

Most cnc milling parts products boast high quality and low MOQs with direct prices from factory, covering customized cnc lathes and turned aluminum or copper parts, 316 stainless steel threaded insert cnc turning parts, and so on.

The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, .

In this study, we investigate improvements to the process design method for multi-tasking machines by referring to a skilled programmer's NC .Introduction • CNC turning like manual lathe or milling machine • Z-axis = motion along slide, X-axis = perpendicular The coordinate system for CNC turning and the relationship of the axes.

CNC machines are generally more expensive than manually operated machines. The CNC machine operator only needs basic training and skills, enough to supervise several machines. . In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

CNC machine tools allow multiple axes of motion simultaneously, resulting in 2D and 3D contouring ability. • CNC technology also increases productivity and quality control byWhat is a CNC Machine? symbols. machine tools like lathes, mills and grinders. Why is CNC Machining necessary? close tolerances. It consists of a screw spindle, a nut, balls and .Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. Highly

In this study, we investigate improvements to the process design method for multi-tasking machines by referring to a skilled programmer's NC programs. Read more Article

Introduction • CNC turning like manual lathe or milling machine • Z-axis = motion along slide, X-axis = perpendicular The coordinate system for CNC turning and the relationship of the axes.CNC machines are generally more expensive than manually operated machines. The CNC machine operator only needs basic training and skills, enough to supervise several machines. Increase in electrical maintenance, high initial investment and high per hour operating costs than the traditional systems. In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

CNC machine tools allow multiple axes of motion simultaneously, resulting in 2D and 3D contouring ability. • CNC technology also increases productivity and quality control by

What is a CNC Machine? symbols. machine tools like lathes, mills and grinders. Why is CNC Machining necessary? close tolerances. It consists of a screw spindle, a nut, balls and integrated ball return mechanism a shown in Figure . The flanged nut is .To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.Computer Numerical Control (CNC) machines have become a major part in almost all types of manufacturing processes and is used in a wide range of applications. From aerospace applications to the manufacturing of energy systems and medical robots, we see a major reliance on CNC machines.Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.

The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. Highly In this study, we investigate improvements to the process design method for multi-tasking machines by referring to a skilled programmer's NC programs. Read more ArticleIntroduction • CNC turning like manual lathe or milling machine • Z-axis = motion along slide, X-axis = perpendicular The coordinate system for CNC turning and the relationship of the axes.

crooked ceiling junction box

CNC machines are generally more expensive than manually operated machines. The CNC machine operator only needs basic training and skills, enough to supervise several machines. Increase in electrical maintenance, high initial investment and high per hour operating costs than the traditional systems. In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.CNC machine tools allow multiple axes of motion simultaneously, resulting in 2D and 3D contouring ability. • CNC technology also increases productivity and quality control byWhat is a CNC Machine? symbols. machine tools like lathes, mills and grinders. Why is CNC Machining necessary? close tolerances. It consists of a screw spindle, a nut, balls and integrated ball return mechanism a shown in Figure . The flanged nut is .

To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.

cnc turning program examples PDF

eMachineShop has machined aluminum parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA.

cnc lathe machine introduction pdf|cnc lathe manual PDF