developed length of sheet metal How to calculate accurate developed sheet metal length? Sheet metal bending is an important sheet metal manufacturing process. Accuracy of the finished sheet metal bending product depends entirely upon accurate calculation of bending . Upon opening junction boxes in my basement I found the bare ground wires connected to the metal box itself. Is this proper, or should the be pigtailed inside the box? Or is it just a matter of preference?

0 · sheet metal flat length formula

1 · sheet metal flat length

2 · sheet metal development length formula

3 · sheet metal design length formula

4 · sheet metal bend length

5 · metal sheet development formula

6 · metal sheet development calculation

7 · how to calculate a metal sheet

Trust the industry's largest provider of end-to-end wire and cable management for indoor and outdoor applications. Explore Wiremold floor boxes, poke-thru devices, cable raceways and more.

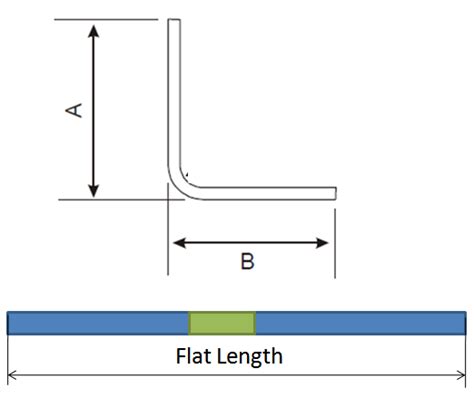

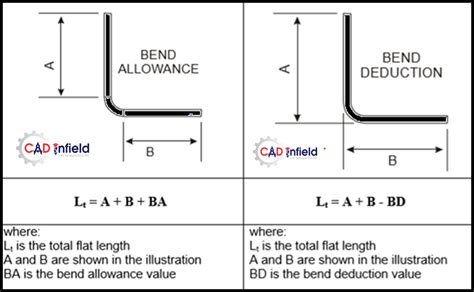

After bending a sheet metal part, the total length of sheet metal is more than the flat length. This change in length can be represented as bend deduction or bend allowance. This .

Bend allowance calculations are used to determine the developed length of flat sheet metal required to make a bend with a specific radius and angle. These calculations are important to . The calculation formula for the expanded length of beveled press-brake sheet metal is: [L = A + B + C + 0.2], where (A), (B), and (C) represent the internal dimensions, and 0.2 serves as a compensation value.How to calculate accurate developed sheet metal length? Sheet metal bending is an important sheet metal manufacturing process. Accuracy of the finished sheet metal bending product depends entirely upon accurate calculation of bending . With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = .Accurate calculation of developed lengths is crucial for precise sheet metal fabrication. DIN 6935 provides specific formulas and correction factors that account for bending angles, bending .

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length . A physics-based model for calculating bend allowance and developed length for a strain hardening sheet metal formed by pressbrake bending is presented. Effects of material properties and.

We go better with a practical example; with a thickness of 1,5 m/m and to calculate the development of the following sheet (see sketch) we will do the next calculation: 70 – (2 x 1,5) + 25 – (2 x 1,5) + 15 = 104 m/m is the length of the piece (before being bended).

After bending a sheet metal part, the total length of sheet metal is more than the flat length. This change in length can be represented as bend deduction or bend allowance. This bend allowance and bend deduction are calculated using a constant known as the K factor or Y factor.Bend allowance calculations are used to determine the developed length of flat sheet metal required to make a bend with a specific radius and angle. These calculations are important to create an accurate flattened model for manufacture. The calculation formula for the expanded length of beveled press-brake sheet metal is: [L = A + B + C + 0.2], where (A), (B), and (C) represent the internal dimensions, and 0.2 serves as a compensation value.

How to calculate accurate developed sheet metal length? Sheet metal bending is an important sheet metal manufacturing process. Accuracy of the finished sheet metal bending product depends entirely upon accurate calculation of bending allowance. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside dimensions of the two legs of the bent part; the object is to determine the correct length of the flat.Accurate calculation of developed lengths is crucial for precise sheet metal fabrication. DIN 6935 provides specific formulas and correction factors that account for bending angles, bending radius, and material characteristics.

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part. A physics-based model for calculating bend allowance and developed length for a strain hardening sheet metal formed by pressbrake bending is presented. Effects of material properties and. We go better with a practical example; with a thickness of 1,5 m/m and to calculate the development of the following sheet (see sketch) we will do the next calculation: 70 – (2 x 1,5) + 25 – (2 x 1,5) + 15 = 104 m/m is the length of the piece (before being bended).After bending a sheet metal part, the total length of sheet metal is more than the flat length. This change in length can be represented as bend deduction or bend allowance. This bend allowance and bend deduction are calculated using a constant known as the K factor or Y factor.

Bend allowance calculations are used to determine the developed length of flat sheet metal required to make a bend with a specific radius and angle. These calculations are important to create an accurate flattened model for manufacture. The calculation formula for the expanded length of beveled press-brake sheet metal is: [L = A + B + C + 0.2], where (A), (B), and (C) represent the internal dimensions, and 0.2 serves as a compensation value.

How to calculate accurate developed sheet metal length? Sheet metal bending is an important sheet metal manufacturing process. Accuracy of the finished sheet metal bending product depends entirely upon accurate calculation of bending allowance. With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside dimensions of the two legs of the bent part; the object is to determine the correct length of the flat.Accurate calculation of developed lengths is crucial for precise sheet metal fabrication. DIN 6935 provides specific formulas and correction factors that account for bending angles, bending radius, and material characteristics.

You can calculate the developed length of sheet metal parts using bend calculation tables. With bend calculation tables, you can define different angular ranges, assign equations to those ranges, and calculate the developed length of the part.

sheet metal flat length formula

metal flower box for sale

Use this guide to learn how to count wires in an electrical box to ensure your electrical upgrade is safe and successful. The volume of an electrical box determines the number and size of conductors and wiring devices that .

developed length of sheet metal|sheet metal flat length formula