soldering sheet metal joints Soldering a particular joint in architectural sheet metal begins with the selection of materials and tools to successfully perform the work. Soldering . Protocase builds custom electronic enclosures and custom rackmounts, in 2-3 days, with no minimum order. Enclosures are fully finished, powdercoated, silkscreened, and in your choice of hardware. Use our free advanced enclosure design tools to save time and money.

0 · types of soldering joints

1 · strength of solder joints

2 · pictures of good solder joints

3 · pictures of bad solder joints

4 · methods of soldering cable joints

5 · how strong are soldered joints

6 · good soldering vs bad

7 · good solder joint vs bad

[Organize and Preserve your Ammo]: Tactical45 Black Ammo Cans Metal Bullet Case Set - 2 Pack Ammo Storage Boxes are designed to store and protect your ammunition and gear from water, dirt, debris, and other elements

basics of how to solder using muriatic acid, cFLUX, map gas, and tri-bar solder. Soldering a particular joint in architectural sheet metal begins with the selection of materials and tools to successfully perform the work. Soldering .They can be joined in a wide range of methods like spot welding, solid welding, rivets, and soldering. Standing Seam Joint. Another common type of sheet metal joint is the standing .

Following these soldering techniques and safety precautions will help you achieve solid and durable solder joints on galvanized sheet metal. Preparing Galvanized Sheet Metal for Soldering. To prepare for soldering, . In this issue, we will discuss the procedure and quality control measures for joint preparation and soldering techniques that must be .Solder is defined as a low melting alloy that is used to join two pieces of metal together. In the roofing trade, the most common makeup of solder will be a mixture of tin and lead. The 3 most common solders for roofing are listed .

If you are soldering any type of sheet metal, it is important to choose the right flux. Flux plays a vital role in soldering as it enhances the bonding of the joints and improves the performance of the soldering process. . The main purpose of spot welding is to create a row of solder joints on two sheet metal parts. This is achieved by melting the local sheet metal material at the welding head to complete the connection between the sheet .

In the February 2021 issue of Florida Roofing, we discussed material selection and quality control measures to improve the quality of soldered architectural sheet metal joints and minimize vulnerability to failure due to thermal movement and water infiltration. In this issue, we will discuss the procedure and quality control measures for joint preparation and soldering techniques that . Soldering, with regards to roofing, is the process of joining two pieces of metal together using solder to create a leak proof seam. When you get started soldering, it may seem difficult to fill the joints properly while maintaining a degree of professionalism. Gobs of solder everywhere is not appealing. Learning how to use solder [.] Key Takeaways. Soldering is a process that joins metals using a filler metal, typically an alloy of tin and lead, which melts at lower temperatures compared to the base metals.; The three main types of soldering are soft soldering, hard soldering and brazing, each varying by the temperature required and the strength of the final joint.; Soldering is widely used in .

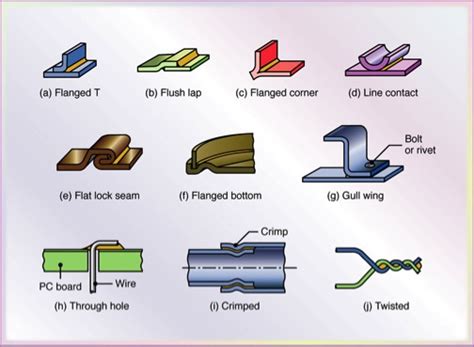

types of soldering joints

This study tests the use of 1/2 inch wide flat lock seam soldered joints. The industry’s current recommended widths are 5/8-inch-wide flat lock seams (Architectural Sheet Metal Manual by SMACNA) and 3/4-inch-wide flat lock seams (Copper and Common Sense by Revere Copper).The joints can be finished by soldering and/or riveting. When developing sheet-metal patterns, ensure you add sufficient material to the base dimensions to make the seams. Several types of seams used to join sheet-metal sections are discussed in this section.Flat Seam Roofs Used in low/no slope areas or areas subject to flooding or standing water Typically made from 20” x 28” sheets – relative geometry is important fro expansion and contraction, sheet use efficiency, and wind load. Copper or stainless steel is recommended Lock and seal all joints, solder joints on slopes less than 3:12 We all know you can easily solder a clean piece of plain steel sheet metal. But something's different if the area was previously galvanized. While learning I wasted 2 new tanks due to excessive heat. Once the zinc was gone I could not make the job look nice. The solder run away from areas missing the zinc coating.

The authoritative public forum for Metal Finishing since 1989 -----Bonding/soldering galvanized sheet metal. Quickstart: Welding galvanized metal is not recommended because of contamination of the weld and the safety issue of breathing the zinc-rich fumes -- removing the zinc with acid first is discussed. Soldering is possible but it also has issues which are considered.The soldering iron and base sheet metal (where fea• by dipping sheet edges into a molten solder bath. Dressing. Dressing is the process of : sible) should be pretinned prior to : hammering down locks and seams ; soldering to facilitate solder low : so that they are lat and tight, and so ; and promote bond of the solder to : that all .

Demonstration of soldering some galvanized metal pieces using an Express Propane Soldering Torch.https://www.stortz.com/product-category/roofing-tools/solder.

Of the three solder types noted above, 50/50 tin-lead solder is the most commonly used in architectural sheet metal applications, as it is readily available and commonly accepted. 60/40 tin-lead solder is closer to the eutectic point of tin-lead alloys, and as such has a lower melting temperature and narrower pasty range. 60/40 solder is .Sheet Metal Soldering Materials (16) Sheet Metal Soldering Materials (16 products) Fluxes, Chemicals & Cleaners (2) Fluxes, Chemicals & Cleaners (2 products) Sheet Metal Soldering Materials (16) Sheet Metal Soldering . They are the most suitable welded joints for sheet metals with different thicknesses. Tee Joint Welding: Tee welding joints are made by placing the two materials intersect at a 90° angle. One sheet metal part is placed at .

The heat from the soldering iron will melt the solder, allowing it to flow into the joint. Apply the solder: As the solder melts, move it along the joint area. Use a steady and controlled motion to ensure the solder evenly coats . After soldering, the residues of flux should be removed by washing thoroughly with water to avoid corrosion. The strength of the soldering joint is relatively low. Soldering is commonly used in electric and electronic applications, Sheet metal work wire terminals, sealing of metal containers, and similar small parts.

Soldering and brazing tends to be used for smaller tasks, such as joining electronic parts, however they can create a strong bond between sheet metal parts through the use of a melted filler metal. These processes can be manual or automated, but brazed joints always require overlapping parts, which will impact the strength of the final joint.Making the Joint. An allowance equal to the width of the overlap must be added to the length of sheet metal used. Ensure the joining surfaces are clean, apply Flux and bring the pieces together.; Small pieces may hold themselves together but larger, more complex or 'springy' joints will need to be held in place until Soldered.; Use weights, clips, split pins or wire, for example, .

strength of solder joints

These include a soldering iron, safety glasses, flux paste, solder wire, and the zinc sheet metal itself. Also, it’s helpful to have tweezers, pliers, and a steel wool scrub pad. When choosing your soldering iron, make sure to select one with an adjustable temperature setting that works well with the type of zinc you plan on using – usually . However, you should never try to heat up a duller solder joint merely for cosmetics. This can cause the joint to be damaged and then you will need to desolder it. Why Dull Solder Joints Might Occur. If your solder joints are not shiny, but a have a duller finish, it is typically just the effect of having a coarse grainy structure in the solder . sheet metal shop.pptx - Download as a PDF or view online for free . SHEET METAL JOINTS There are three type of joints: 1. Mechanical joints 2. Metallic joints 3. Riveted joints . Stakes 13. Soldering Iron Theory :- What is sheet metal shop and its uses. Procedure :- Write Point Wise 39. RESULTS :- ALL DIMENSIONS ARE IN MM Download.This seam is similar to the slip expansion seam. The difference is in forming the lock. Where as the slip expansion lock is formed by braking a sheet of copper, the lock on this seam is formed by soldering a small strip of copper below the sheet. Download CAD File

Work may involve any of the following: setting up and operating fabricating machines to cut, bend, and straighten sheet metal; shaping metal over anvils, blocks, or forms using hammer; operating soldering and welding equipment to join sheet metal parts; or inspecting, assembling, and smoothing seams and joints of burred surfaces. Includes sheet . Shop Stortz for a first class offering of sheet metal tools. Mechanical Lock Seamers; Power Seamers; Seaming Anvils; . Soldering has been common practice in the metal roofing trade to ensure water tight joints and to strengthen seams. While some purists may frown upon using solder to mend together two pieces of metal, there is one thing for . When it comes to soldering sheet metal panels, it is recommended to use a solder with a low melting point, such as a lead-based solder or a tin-based solder. These types of solders melt at temperatures below 450°F (232°C) and are commonly used for joining sheet metal due to their lower melting points and good adhesion properties.

metal nest box parrots

metal or plastic thermostat housing

CNC Lathe For Sale, CNC Lathe Inventory Updated Daily, Buy Direct From Used .

soldering sheet metal joints|strength of solder joints