copper cnc machining manufacturers With a well-equipped machine shop, our seasoned technicians can perform CNC milling, turning, wire EDM, 5 axis machining, and more processes for creating prototypes and end-use CNC copper parts. Our engineers will help you . To remove duct tape glue, you can use rubbing alcohol or a commercial adhesive remover. Simply apply the solution to the affected area and allow it to sit for a few minutes before gently rubbing the area with a soft cloth.

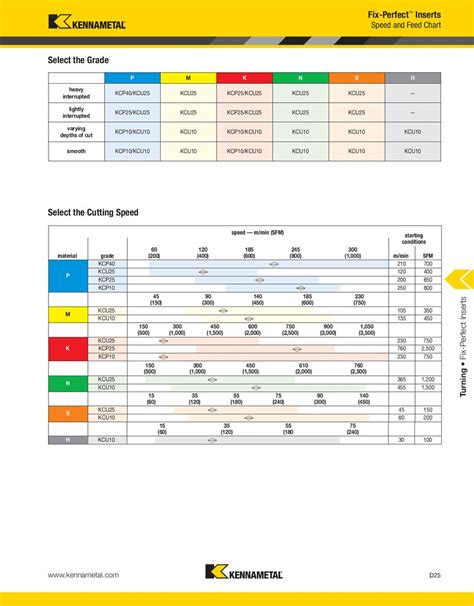

0 · turning copper speeds and feeds

1 · speeds and feeds for copper

2 · machinability of copper 110

3 · end mills for copper

4 · cutting speed for copper milling

5 · copper segregation procedure machine shop

6 · copper segregation policy machine shop

7 · copper machinability chart

Unfortunately the ring is a standard size flood light expecting a standard round electrical box. It doesn't fit the existing so it won't have a complete seal allowing water to enter .

Copper is an incredibly versatile metal, making it an optimal choice for producing CNC machined custom parts. The alloy has several useful properties alongside its versatility—this is why companies working in industries such as electrical, construction, . See moreWe offer a complete copper CNC machining service and can produce complex copper parts inC110 andC101. Copper parts are . See moreProtolabs Network offers a state-of-the-art copper CNC machining service, guaranteeing consistent quality and fast turnaround times. We have over 1,600 milling and turning machines at our disposal, which means capacity is virtually always available and . See moreBe-cu prototyping company provides a range of solutions for the machining of copper parts. Red copper is therefore also classified as copper alloys.

With a well-equipped machine shop, our seasoned technicians can perform CNC milling, turning, wire EDM, 5 axis machining, and more processes for creating prototypes and end-use CNC copper parts. Our engineers will help you .

Precision Machining: We utilize advanced CNC milling and turning machines to ensure precise tolerances and high-quality finishes. Versatile Fabrication Techniques: Our expertise includes .Depending on requirements, PTS manufactures customized copper components in turning and milling or in cold forming tumbling presses. CNC machining and cold forming. With the latest . What Is Copper CNC Machining? Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such .

Cutting Edge Bullets are manufactured out of solid copper on CNC Swiss Style Lathes. These machines are capable of holding extremely strict tolerances and frequently used in the manufacturing of precision parts for aerospace, medical, .

Copper machining is the specialized precision machining of customer designed copper components from cold headed blanks, copper blanks, or solid copper bars. Copper is a very difficult metal to machine and requires specialized .We offer a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics.Be-cu prototyping company provides a range of solutions for the machining of copper parts. Red copper is therefore also classified as copper alloys.With a well-equipped machine shop, our seasoned technicians can perform CNC milling, turning, wire EDM, 5 axis machining, and more processes for creating prototypes and end-use CNC copper parts. Our engineers will help you improve the design and reduce the cost, you can upload your CAD files to get a free online quote.

Precision Machining: We utilize advanced CNC milling and turning machines to ensure precise tolerances and high-quality finishes. Versatile Fabrication Techniques: Our expertise includes welding, brazing, stamping, and other fabrication methods to create components that meet your exact specifications. Our Commitment to Quality:Depending on requirements, PTS manufactures customized copper components in turning and milling or in cold forming tumbling presses. CNC machining and cold forming. With the latest CNC machines, we manufacture precision copper components to exact and tight tolerance standards. What Is Copper CNC Machining? Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts.Cutting Edge Bullets are manufactured out of solid copper on CNC Swiss Style Lathes. These machines are capable of holding extremely strict tolerances and frequently used in the manufacturing of precision parts for aerospace, medical, and automotive.

Copper machining is the specialized precision machining of customer designed copper components from cold headed blanks, copper blanks, or solid copper bars. Copper is a very difficult metal to machine and requires specialized process knowledge for manufacturing.

turning copper speeds and feeds

speeds and feeds for copper

YIJIN Hardware offers a comprehensive range of copper CNC machining services, including: 3, 4, and 5-axis CNC Milling for complex geometries. Turning, Drilling, and Tapping for custom copper parts. Rapid Prototyping and Large-Scale Production to accommodate your project’s size, whether you need a prototype or a high-volume order.

With years of experience in machining copper, Portland Precision can produce tight tolerance, precision copper parts that match your design specifications.

We offer a complete copper CNC machining service and can produce complex copper parts in C110 and C101. Copper parts are corrosion resistant and versatile and can be used for applications requiring electrical conductivity and higher quality aesthetics.

Be-cu prototyping company provides a range of solutions for the machining of copper parts. Red copper is therefore also classified as copper alloys.

With a well-equipped machine shop, our seasoned technicians can perform CNC milling, turning, wire EDM, 5 axis machining, and more processes for creating prototypes and end-use CNC copper parts. Our engineers will help you improve the design and reduce the cost, you can upload your CAD files to get a free online quote.Precision Machining: We utilize advanced CNC milling and turning machines to ensure precise tolerances and high-quality finishes. Versatile Fabrication Techniques: Our expertise includes welding, brazing, stamping, and other fabrication methods to create components that meet your exact specifications. Our Commitment to Quality:Depending on requirements, PTS manufactures customized copper components in turning and milling or in cold forming tumbling presses. CNC machining and cold forming. With the latest CNC machines, we manufacture precision copper components to exact and tight tolerance standards. What Is Copper CNC Machining? Copper CNC machining involves using computer-controlled tools and machines to fabricate copper materials into desired shapes. The CNC machining process controls complex devices such as mills, grinders, and lathes to make precise and intricate features on copper parts.

Cutting Edge Bullets are manufactured out of solid copper on CNC Swiss Style Lathes. These machines are capable of holding extremely strict tolerances and frequently used in the manufacturing of precision parts for aerospace, medical, and automotive.Copper machining is the specialized precision machining of customer designed copper components from cold headed blanks, copper blanks, or solid copper bars. Copper is a very difficult metal to machine and requires specialized process knowledge for manufacturing.

YIJIN Hardware offers a comprehensive range of copper CNC machining services, including: 3, 4, and 5-axis CNC Milling for complex geometries. Turning, Drilling, and Tapping for custom copper parts. Rapid Prototyping and Large-Scale Production to accommodate your project’s size, whether you need a prototype or a high-volume order.

machinability of copper 110

end mills for copper

Here we describe matching 15-Amp receptacles to 15-Amp circuits, 20-Amp receptacles to 20-Amp circuits, two-wire receptacles where no ground is present, GFCI and AFCI electrical receptacles, and the proper electrical box to hold and mount these devices.

copper cnc machining manufacturers|copper segregation policy machine shop