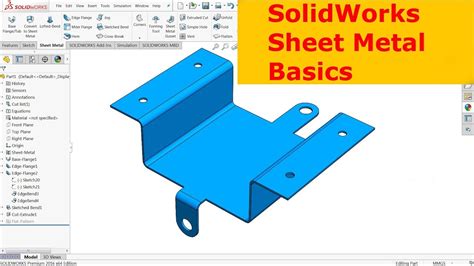

convert to sheet metal In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create . Most expert welders suggest the arc welding method when it comes to connecting slim-gauge metals. Nonetheless, you can overcome the challenges of connecting thin materials using a couple of welding procedures. If you would like to know how to weld slim metal, then keep reading to learn more.

0 · solid work to sheet metal conversion

1 · solid work to sheet metal

2 · solid to sheet metal worksheets

3 · convert solid part to sheet metal

4 · convert solid metal to sheet metal

San Diego Welding - Welding San Diego - Metal Fabrication San Diego = Care .

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. Create the solid part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . Select Use gauge table.In the Convert to Sheet Metal PropertyManager, you specify the fixed .“Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal .

In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create .

This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal. How to use the Convert to Sheet metal feature in Solidworks Sheet Metal. The convert to sheet metal feature is perfect for creating sheet metal parts from no.You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features .

Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. . Converting parts to sheet metal ensures compatibility and seamless integration within an assembly. Step 1: Create the solid part. Step 2: Convert to sheet metal. Click Convert to Sheet Metal (Sheet Metal toolbar) or . “Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal models, from there a flat pattern can be automatically created. This is a useful tool if the initial part has been created using standard part . You probably, normally, come across a sketch and pull-edge type of flange to create sheet met. Learn about this tip for those who use #SOLIDWORKS sheet metal.

The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. Create the solid part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . Select Use gauge table.

solid work to sheet metal conversion

In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part. The SOLIDWORKS Convert to Sheet Metal command is an efficient way to create Sheet Metal geometry without having to be proficient in using Sheet Metal features.

sheet metal laser cutting designs

This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal.How to use the Convert to Sheet metal feature in Solidworks Sheet Metal. The convert to sheet metal feature is perfect for creating sheet metal parts from no.You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features to it. Use the Convert to Sheet Metal tool with: Solid or surface bodies that have: No shells or fillets; Either a shell or fillets; Both a shell and fillets

Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. Method 1: Use the Convert to Sheet Metal tool; Method 2: Insert Rips and Bends into the part Converting parts to sheet metal ensures compatibility and seamless integration within an assembly. Step 1: Create the solid part. Step 2: Convert to sheet metal. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal. Step 3: Sheet metal gauge table. “Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal models, from there a flat pattern can be automatically created. This is a useful tool if the initial part has been created using standard part modeling features such as extrudes and lofts.

solid work to sheet metal

You probably, normally, come across a sketch and pull-edge type of flange to create sheet met. Learn about this tip for those who use #SOLIDWORKS sheet metal.The Convert to Sheet Metal command lets you specify the thickness, bends, and rips necessary to convert a solid part to a sheet metal part. Create the solid part. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal . Select Use gauge table.

In the Convert to Sheet Metal PropertyManager, you specify the fixed face and thickness of the sheet metal part, the default bend radius, and the edges or fillet faces on which to create bends. If an edge already has a fillet applied, the radius of the fillet is used as the bend radius for the new sheet metal part. The SOLIDWORKS Convert to Sheet Metal command is an efficient way to create Sheet Metal geometry without having to be proficient in using Sheet Metal features.

This video demonstrates how to use the Convert to Sheet Metal command in SolidWorks 2020 for prisms and pyramids. Also, I demonstrate how to edit sheet metal.

How to use the Convert to Sheet metal feature in Solidworks Sheet Metal. The convert to sheet metal feature is perfect for creating sheet metal parts from no.You can create a sheet metal part by converting a solid or surface body using the Convert to Sheet Metal tool. After you create the sheet metal part, you can apply all sheet metal features to it. Use the Convert to Sheet Metal tool with: Solid or surface bodies that have: No shells or fillets; Either a shell or fillets; Both a shell and fillets

Once you have a Solid Body in the shape that you want, there are a couple of ways to convert it into Sheet Metal. The method you choose will depend on the state of the Solid Body and the features you want in the Feature Tree. Method 1: Use the Convert to Sheet Metal tool; Method 2: Insert Rips and Bends into the part Converting parts to sheet metal ensures compatibility and seamless integration within an assembly. Step 1: Create the solid part. Step 2: Convert to sheet metal. Click Convert to Sheet Metal (Sheet Metal toolbar) or Insert > Sheet Metal > Convert To Sheet Metal. Step 3: Sheet metal gauge table.

“Convert to Sheet Metal” allows the user to quickly convert parts into sheet metal models, from there a flat pattern can be automatically created. This is a useful tool if the initial part has been created using standard part modeling features such as extrudes and lofts.

solid to sheet metal worksheets

sheet metal local 177

sheet metal lattice

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

convert to sheet metal|solid work to sheet metal conversion