why do you use metal boxes for wiring Electrical boxes encase wire connections to protect them from short circuits. They . Following these steps, you can successfully replace a damaged piece of mobile home sidingand restore your home’s exterior to its original beauty. Remember always to . See more

0 · wiring a metal box

1 · when to use electrical box

2 · metal electrical boxes

3 · metal electrical box safety

4 · metal electrical box problems

5 · metal box electrical wire

6 · electrical box wiring

7 · electrical box vs metal box

Get your bearings with a dedicated, waterproof relay box. Like a trail map for your wiring, our relay box is the most efficient way to consolidate, organize, and keep track of all your aftermarket accessories.

wiring a metal box

Strong, fireproof, and incapable of melting, metal boxes offer the greatest level of security for all electrical wiring applications. Compared to plastic boxes, metal electrical boxes are very strong: It is virtually impossible to bend, warp, twist, or crush metal electrical or junction .

15 amps: A cable labeled "14-2 with ground" will have two insulated conductors with .Larry Campbell is an electrical contractor with 36 years of experience in .It also prevents the cable from rubbing against the edge of the box and .

standing seam metal roofing brackets

when to use electrical box

Electrical boxes encase wire connections to protect them from short circuits. They .

If you're looking to wire an electrical metal box, then you've come to the right place! In this video, we'll teach you the basics of wiring a metal box, including the different types of. Metal electrical boxes have been in use for a long time and offer distinct advantages over their plastic counterparts. Here are some reasons to consider using metal boxes: Superior Strength and Durability: Metal boxes are . The purpose of electrical boxes. Wiring connections—where wires join an outlet, switch or other wires—must be inside an electrical box. Here’s why: Connections are the weak link in an electrical system. If they get damaged, . For many applications, the biggest advantage of a metal junction box is its durability. Metal junction boxes can withstand a huge variety of adverse environmental conditions, including crushing impacts, open flames and .

Plastic boxes are the most common choice for residential wiring projects. They are lightweight, easy to install, and less expensive than metal options. Plastic boxes are also non-conductive, reducing the risk of electrical .

Knowing when to use each type can save you time, money, and potential headaches. This guide will discuss the pros and cons of plastic and metal junction boxes, . Use a metal electrical box when metal-sheathed cable (also called armored BX cable) or metal conduit is running in or out of the box. Metal cable and conduit depend on the contact from its metal sheathing to the metal box .On metal boxes, most receps self-ground. Once you have done that, you have a receptacle whose metal "yoke" (the ears the screws go through) making hard clean metal contact with the metal box; no paint, rust or little screw-holder .

Examine the wiring of anything from a light switch to a ceiling fan to an industrial control panel, and you very well might find a metal junction box protecting the wiring. Metal electrical boxes are known for their durability and . As we are learning to install a quality electrical product during our apprenticeships, we are constantly reminded to bond our metallic boxes. But why do we b. Metal boxes should be used: When metal-sheathed cable or metal conduit is running in or out of the box. For interior exposed application such as in an unfinished basement or mudroom where there's no drywall. You can use a metal box for NM wiring, but special precautions should be taken to ensure proper grounding. Weatherproof Electrical Boxes

stanley green metal lunch box

Then you pull out the two screws from the junction box and use them to affix the metal cover to the box. Tip: Always wire the receptacles before installing in the cover, the raised lip makes it near impossible to get the wires around the screws correctly and to tighten the screws.

The holes in the side of the metal box do not allow me to screw it in the stud becaus I neeed 1/2” out for drywall and the holes are flush to the edge of the box. . Tip#2. Take a good look at your condelet. The wire fill may require you to use a bigger size condelet (a.k.a. "LB"). I typically upsize condelet and utilize reducing bushings .

There are some different rules when hooking up in plastic outlet boxes. You have to use plastic face plates with plastic screws because metal ones won't be grounded, and must connect a ground wire to the yoke of the device. . Metal boxes are considered bonded if connected to the ground wire or if metal conduit and fittings are used. See .

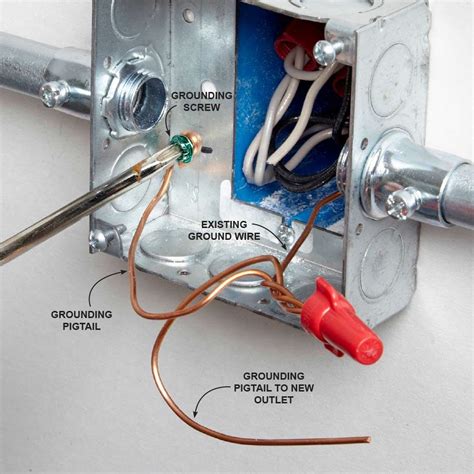

Metal boxes, EMT, Special wiring, you deserve nothing less. infinity Moderator. Staff member. Location New Jersey Occupation Journeyman Electrician Dec 20, 2010 . ask why we didn't use metal boxes in their bathroom remodel. My immediately responded, "why would we have used them?". I know that he might say that the box would be grounded . All My Favorite DIY Electrical Tools - https://www.amazon.com/shop/everydayhomerepairs Do you feel comfortable using metal electrical boxes on your DIY elect. Years ago did some work in a office building built in 1979, wiring was NM cable with suspended ceilings, now prohibited, but whoever wired it ran NM cable to one & two gang nail on plastic boxes on the trusses to supply the lights, they then ran 1/2" steel flex from the boxes to the 2X4 troffers, which each suite had 8 of, with 4-F40 lamps in .If you have emt ran circuits with metal boxes you can attach the ground wire to the box using a 10-32 screw with pigtail wire splice and wire nut (green by code) or just buy a premade grounding pigtail from the hardware store. (Check ideal brand, most common gauge they sell is 12 but they are OK to use with 14 size cable) .

I am student at a technical college. We were doing a project in the lab using electrical nonmetallic tubing and nonmetallic double gang boxes. The question came up as to why we could not use metal switch rings on nonmetallic boxes and I could not seem to find where specifically stated this in the 2011Nec codebook The ends of the yoke may also have removable drywall ears. Notice also the metal box has metal where the screw goes in. If all these things are true: The metal box is flush to the wall, and the surrounding wall surface is not proud of it ; The metal parts on both receptacle and box are bare and free of rust, paint or other contaminants

Be sure you use a 30A double-pole breaker to adequately protect your wiring. Make sure you provide an equipment ground and use a NEMA 14-30 receptacle. The box can be metal or plastic. Some form of cable clamp is always required, it's just that most plastic boxes have an integrated clamp (that finger-trap style door).The right time to use an electrical conduit is when you are manually running wire for electricity, or when re-wiring a building. Before using a conduit, be sure to check your local building codes and regulations; there are sometimes . I realize you ground the metal box and the receptacle in EACH box. My first question was whether the method someone gave to me was correct. Here is the method - connect both the incoming and the outgoing ground to .

(remember you are not allowed to use a device to daisy-chain a ground connection; doing so means if you remove the device, you sever ground for downline devices). Ground to the metal box first. The metal box should always be grounded. If you need to ground 2 or more wires, then use a pigtail and wire nut. The receptacle may not need a ground wire One of the single pole switch boxes had a single ground (no bundle) that came through into the box and was tucked to the back of the box. That was the most confusing because how simple was it just to connect to the ground screw on the light switch. However the 2 other boxes had a bundle come through and just pushed to the back. Being a metal conduit, it has an advantage over PVC conduits which cannot bend. It may also serve as the grounding path although some local codes may require that you also run a green grounding wire. The Basics of Flexible Metal Conduit. Flexible metal conduits are made from steel or aluminum by coiling a self-interlocking ribbed strip of the . After opening the outlet up, it appears that the metal box has no grounding screw and the existing grounding wires are wrapped behind the mounting screws (the box has two mounting bracket, one on the top and one on the bottom and each bracket has some space to the back of the box - see the picture).

Upon opening junction boxes in my basement I found the bare ground wires connected to the metal box itself. Is this proper, or should the be pigtailed inside the box? . and there should be a 10/32 screw hole to attach the bond wire to. You can also buy bond wires with the screw attached. The mysteries of life: "It's faster horses, younger .No, not "too". You ground the metal box INSTEAD. And then you either use hard flush contact with the yoke, or better receptacles marked "Self-grounding", to deliver ground to the receptacle. None of that is required to deliver ground to a switch, it picks it up via the mounting screws.

Box sizing is the process of choosing the right size and type of electrical box for a wiring project. Electrical boxes are metal or plastic containers that house wires, switches, outlets and other devices. They provide protection and support for the electrical connections and prevent accidental contact with live wires. One of the important steps in box sizing is installing cable .

Surface-mounted electrical boxes for all electrical fixtures must be raintight/weatherproof. . Wiring buried inside rigid metal (RMC) or intermediate metal (IMC) conduit must have at least 6 inches of earth cover; wiring in PVC conduit must have at least 18 inches of cover. . on the ground. You can use power equipment to dig no closer than . If you fully connect the system with metal boxes, and the grounding is continuous, then I would run stranded THHN wire, it's unfairly easy to pull, and 2 wires is all you need. Pigtail your receptacles with solid wire; combining solid+stranded on a wire nut is easy but landing stranded on a receptacle screw is hard.

All My Favorite Tools - https://www.amazon.com/shop/everydayhomerepairs Metal electrical boxes have many advantages over their plastic counterparts but there.

So it's not enough that the ground wire inside the MC be connected properly at each end. If I'm following you correctly, the metal jacket also has to be bonded. to ensure that it is grounded. If it's terminated In a metal box, then takes care of that. If not, then you have to use bonding bushings to make sure the metal jacket is grounded?

metal electrical boxes

$75.99

why do you use metal boxes for wiring|metal electrical box problems