bending sheet metal box It is also possible to bend and flatten a hem, to form a radius, and to bend a zig-zag. The standard procedure for making a simple bend in sheet metal using a hand brake . Enclosure for electrical installations. Electrical installations in a vault, room, closet or in an area surrounded by a wall, screen, or fence, access to which is controlled by lock and key or other .

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

A junction box, also known as an electrical junction box or junction can, is an enclosure that connects and splits electrical wires and cables. Junction boxes permit access to wiring for maintenance, inspection, and installation.

Once the hems have been made the next step is to bend your metal into a box. You will be working with a sheet metal brake to complete this step. The goal here is to clamp your brake .

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal . It is also possible to bend and flatten a hem, to form a radius, and to bend a zig-zag. The standard procedure for making a simple bend in sheet metal using a hand brake . Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan brake. .more. Creating a 22 gauge sheetmetal box from scratch.Once the hems have been made the next step is to bend your metal into a box. You will be working with a sheet metal brake to complete this step. The goal here is to clamp your brake teeth right on your lines. If your line is clamped down at an angle to your brake teeth, you will bend your metal at an angle and your box will not come out as you .A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

It is also possible to bend and flatten a hem, to form a radius, and to bend a zig-zag. The standard procedure for making a simple bend in sheet metal using a hand brake machine is as follows: 1. Insert sheet metal under clamping bar. 2. Adjust clamping handle cam for metal thickness. 3. Measure and position the sheet metal edge the correct . Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.--.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. How do I bend and form the sheet metal for the box? Use a metal brake to bend the edges of the sheet metal to the desired angle. Make sure to use the appropriate tooling and settings for the thickness of the sheet metal.In this plan, we’ll show you how to build and use a simple bending brake like you see here. It makes crisp, clean bends on sheet metal (up to 22 ga.) for great-looking results. It’s made from a few pieces of hardwood to form the base and hinged handle. Video tutorial includes cutting the sheetmetal template and bending the pieces on my 24" Grizzly Box & Pan brake. .more. Creating a 22 gauge sheetmetal box from scratch.

Once the hems have been made the next step is to bend your metal into a box. You will be working with a sheet metal brake to complete this step. The goal here is to clamp your brake teeth right on your lines. If your line is clamped down at an angle to your brake teeth, you will bend your metal at an angle and your box will not come out as you .

A Riveted Metal Box With Lid: This is a practice box, so it's not very nice-looking. You can build it to get a feel for working with various sheet metal tools: metal shears, box brakes, pop-rivets, and so on. We're not going to touch upon bend radii or bend allowances, but these. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. It is also possible to bend and flatten a hem, to form a radius, and to bend a zig-zag. The standard procedure for making a simple bend in sheet metal using a hand brake machine is as follows: 1. Insert sheet metal under clamping bar. 2. Adjust clamping handle cam for metal thickness. 3. Measure and position the sheet metal edge the correct .

types of bending sheet metal

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. How To Bend Sheet Metal Without A Brake:How To Bend Sheet Metal Without A Brake in 4 different methods with minimal or homemade tools.--.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

How do I bend and form the sheet metal for the box? Use a metal brake to bend the edges of the sheet metal to the desired angle. Make sure to use the appropriate tooling and settings for the thickness of the sheet metal.

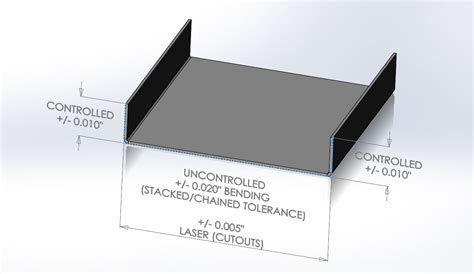

sheet metal bending standards

exterior metal tiny house

external satellite cable junction box

sheet metal bending near me

Music box, mechanical musical instrument that is sounded when tuned metal prongs, or teeth, mounted in a line on a flat comb are made to vibrate by contact with a revolving cylinder or disc that is driven by a clockwork mechanism. As the cylinder or disc revolves, small pins or .

bending sheet metal box|problems with sheet metal bending