benefits of cnc machining CNC machining and milling is much better than traditional methods of machining. It enables high precision, repeatability and efficiency. Let’s Explore! In this article, we’ll explore the many benefits of CNC machining and milling. These benefits . Marvel Allure Blaster Box (Upper Deck) Configuration: 5 packs per box. 4 Cards per Pack. . Marvel Spider-Man Metal Universe Trading Cards Blaster Box (Upper Deck) Regular Price: .

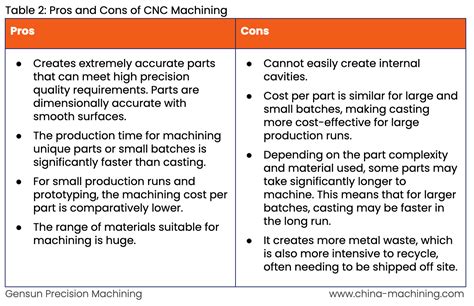

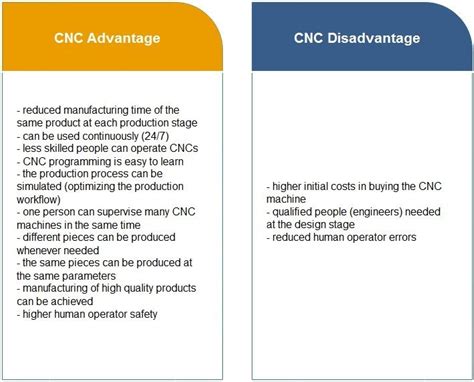

0 · pros and cons of machining

1 · disadvantages of cnc milling

2 · disadvantages of cnc

3 · cnc milling pros and cons

4 · cnc milling advantages and disadvantages

5 · cnc machining advantages and disadvantages

6 · cnc machine pros and cons

7 · cnc advantages and disadvantages

Universal Sheet Metal is located in Houston, Texas. This organization primarily operates in the Sheet Metalwork business / industry within the Fabricated Metal Products sector. This organization has been operating for approximately 28 years.

Learn more about each benefit and the importance of CNC machining. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or .CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry. It offers unmatched precision, efficiency, and versatility, making it an . This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, . CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process

CNC machining and milling is much better than traditional methods of machining. It enables high precision, repeatability and efficiency. Let’s Explore! In this article, we’ll explore the many benefits of CNC machining and milling. These benefits .

CNC machining produces everything from vehicle armor to weapon systems with the precision and consistency necessary for high-stakes applications. CNC machines can .One of the most significant benefits of CNC machining is its ability to produce parts with unparalleled precision and accuracy. By using computer-controlled machines, it ensures that every component is crafted to exact specifications, .

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the . One of the primary benefits of CNC machining is its exceptional precision and accuracy. CNC (Computer Numerical Control) machines are capable of producing parts with .

pros and cons of machining

Learn more about each benefit and the importance of CNC machining. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes.CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry. It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends. This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, making it ideal for high-precision and large-volume production.

CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process

CNC Machining Produces Little to No Waste; Zero Defects and Greater Accuracy; Faster and Efficient Production; Quicker Assembly; Enhanced Personnel Safety; Reduction in Energy Consumption; CNC Machining Leads to Lower Production Costs; Conclusion

CNC machining and milling is much better than traditional methods of machining. It enables high precision, repeatability and efficiency. Let’s Explore! In this article, we’ll explore the many benefits of CNC machining and milling. These benefits include their impact on production volume, labor needs and material use. CNC machining produces everything from vehicle armor to weapon systems with the precision and consistency necessary for high-stakes applications. CNC machines can create parts for military-grade vehicles that must meet strict standards for durability and performance.One of the most significant benefits of CNC machining is its ability to produce parts with unparalleled precision and accuracy. By using computer-controlled machines, it ensures that every component is crafted to exact specifications, eliminating the risk of human error.CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal. 1. Precision and Consistency. CNC milling machines offer exceptional precision.

One of the primary benefits of CNC machining is its exceptional precision and accuracy. CNC (Computer Numerical Control) machines are capable of producing parts with incredibly tight tolerances, ensuring that each piece meets the exact specifications of the design. Learn more about each benefit and the importance of CNC machining. CNC machining, or computer numerical control machining, is a manufacturing process that utilizes computer-aided machines to cut metal or other materials into intricate patterns and shapes.CNC, or computer numerical control machining, is a revolutionary technology transforming the manufacturing industry. It offers unmatched precision, efficiency, and versatility, making it an essential tool for engineers and product developers. This blog delves into the crucial benefits of CNC machining, its applications, and emerging trends. This article will explore the main benefits of CNC machining and why it might be the right choice for your production needs. Key Takeaways. CNC machining offers unmatched precision, consistency, and increased efficiency, making it ideal for high-precision and large-volume production.

CNC machining comes with several benefits. The most widely accepted benefits across several industries include the following: Improves accuracy of the machining process CNC Machining Produces Little to No Waste; Zero Defects and Greater Accuracy; Faster and Efficient Production; Quicker Assembly; Enhanced Personnel Safety; Reduction in Energy Consumption; CNC Machining Leads to Lower Production Costs; ConclusionCNC machining and milling is much better than traditional methods of machining. It enables high precision, repeatability and efficiency. Let’s Explore! In this article, we’ll explore the many benefits of CNC machining and milling. These benefits include their impact on production volume, labor needs and material use. CNC machining produces everything from vehicle armor to weapon systems with the precision and consistency necessary for high-stakes applications. CNC machines can create parts for military-grade vehicles that must meet strict standards for durability and performance.

One of the most significant benefits of CNC machining is its ability to produce parts with unparalleled precision and accuracy. By using computer-controlled machines, it ensures that every component is crafted to exact specifications, eliminating the risk of human error.

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal. 1. Precision and Consistency. CNC milling machines offer exceptional precision.

metal fabric 1 2

metal enclosures manufacturers

©2020 United Metal Fabricators Inc. dba UMF Medical Specifications › Height: min. 18.5” (± .5”) 46.9cm (±1.27cm) at seat max. 37” at seat (93.9cm) › Width: 28” (71.12cm) › Length: 57” – 76” with foot section extended (144.7cm - 193cm) › Leg Rest: 19” W x 13” DUMF Medical’s world-class exam room solutions include power exam tables and chairs, procedure chairs, casework, mobile cabinets, IV poles, stainless steel tables, physician stools, .

benefits of cnc machining|cnc advantages and disadvantages