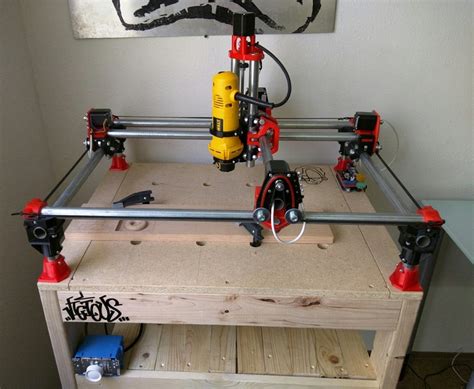

3d printed cnc machine v3 Just as mentioned with my previous version, if you want to build this machine yourself you can download all the necessary files but I don't have enough time to give you much support so build it at your own risk! Also always be very careful with powertools, and only use them if you know what you're doing. See more For distributions made after December 31, 2023, a distribution to a domestic abuse victim may be made from a 403 (b) plan and is not subject to the 10% additional tax on early distributions.

0 · mostly 3d printed cnc

1 · convert 3d printer to cnc

2 · best 3d printer for cnc

3 · 3d printing milling machine

4 · 3d printer diy cnc milling

5 · 3d printer diy cnc lathe

6 · 3d printed cnc router plans

7 · 3d printable cnc machine

Footway covers come in six basic sizes: small, medium, large, square, twin and triple, although there are size variants within some types. All sizes are approximate. These lids cover boxes .

Just as mentioned with my previous version, if you want to build this machine yourself you can download all the necessary files but I don't have enough time to give you much support so build it at your own risk! Also always be very careful with powertools, and only use them if you know what you're doing. See moreCheck out the Wiki for specific milling info and parameter settings. See more This is the third version of my DIY homemade CNC machine. Instead of using threaded rods I'm now using (GT2) belts and it has a larger working area of 50x70 .

This is a modified version of my previous homemade CNC machine. Instead of using threaded rods this one uses (GT2) belts and has a larger working area.

I've designed the 3D printed parts with Fusion 360 and used Inkscape for the Y axis drilling template. To control the machine I'm using an Arduino UNO with GRBL firmware and an . This is the third version of my DIY homemade CNC machine. Instead of using threaded rods I’m now using (GT2) belts and it has a larger working area of 50×70 cm or 20×27 inch. By using belts it’s also faster. To get .

Link to my V2 CNC machine reddit post: https://www.reddit.com/r/3Dprinting/comments/ju3tq4/i_designed_and_3d_printed_my_own_cnc_router/ Machine specs: Three Nema 23 and one Nema 17 motor

This is a short update video to let you know that my CNC Machine V3 is now available as a FreeCAD model if you want to make any changes to it. Check the Mode. This is a modified version of my previous homemade CNC machine. Instead of using threaded rods this one uses (GT2) belts and has a larger working area of 50x70 cm or 20x27 inch. By using belts it's also faster. This is the third version of my DIY homemade CNC machine. Instead of using threaded rods I’m now using (GT2) belts and it has a larger working area of 50×70 cm or .

G300 - 3D Printed CNC Machine: About 6 months ago I started designing a cnc machine that allowed me to carry out some milling works; the design phase was very demanding in terms of time because it involved both the mechanical and .I've designed the 3D printed parts with Fusion 360 and used Inkscape for the Y axis drilling template. To control the machine I'm using an Arduino UNO with GRBL firmware and an Arduino CNC Shield. There are plenty of tutorials to find on how .This is the third version of my DIY homemade CNC machine. Instead of using threaded rods I'm now using (GT2) belts and it has a larger working area of 50x70 .

This is a modified version of my previous homemade CNC machine. Instead of using threaded rods this one uses (GT2) belts and has a larger working area.I've designed the 3D printed parts with Fusion 360 and used Inkscape for the Y axis drilling template. To control the machine I'm using an Arduino UNO with GRBL firmware and an Arduino CNC Shield. There are plenty of tutorials to find on how . This is the third version of my DIY homemade CNC machine. Instead of using threaded rods I’m now using (GT2) belts and it has a larger working area of 50×70 cm or 20×27 inch. By using belts it’s also faster. To get a better understanding of the machine, also check the previous version here:

Link to my V2 CNC machine reddit post: https://www.reddit.com/r/3Dprinting/comments/ju3tq4/i_designed_and_3d_printed_my_own_cnc_router/ Machine specs: Three Nema 23 and one Nema 17 motorThis is a short update video to let you know that my CNC Machine V3 is now available as a FreeCAD model if you want to make any changes to it. Check the Mode.

This is a modified version of my previous homemade CNC machine. Instead of using threaded rods this one uses (GT2) belts and has a larger working area of 50x70 cm or 20x27 inch. By using belts it's also faster. This is the third version of my DIY homemade CNC machine. Instead of using threaded rods I’m now using (GT2) belts and it has a larger working area of 50×70 cm or 20×27 inch. By using belts it’s also faster. To get a better understanding of the machine, also check the previous version here:G300 - 3D Printed CNC Machine: About 6 months ago I started designing a cnc machine that allowed me to carry out some milling works; the design phase was very demanding in terms of time because it involved both the mechanical and the electronic parts. I decided to call this mac.I've designed the 3D printed parts with Fusion 360 and used Inkscape for the Y axis drilling template. To control the machine I'm using an Arduino UNO with GRBL firmware and an Arduino CNC Shield. There are plenty of tutorials to find on how .

This is the third version of my DIY homemade CNC machine. Instead of using threaded rods I'm now using (GT2) belts and it has a larger working area of 50x70 .This is a modified version of my previous homemade CNC machine. Instead of using threaded rods this one uses (GT2) belts and has a larger working area.I've designed the 3D printed parts with Fusion 360 and used Inkscape for the Y axis drilling template. To control the machine I'm using an Arduino UNO with GRBL firmware and an Arduino CNC Shield. There are plenty of tutorials to find on how .

This is the third version of my DIY homemade CNC machine. Instead of using threaded rods I’m now using (GT2) belts and it has a larger working area of 50×70 cm or 20×27 inch. By using belts it’s also faster. To get a better understanding of the machine, also check the previous version here: Link to my V2 CNC machine reddit post: https://www.reddit.com/r/3Dprinting/comments/ju3tq4/i_designed_and_3d_printed_my_own_cnc_router/ Machine specs: Three Nema 23 and one Nema 17 motorThis is a short update video to let you know that my CNC Machine V3 is now available as a FreeCAD model if you want to make any changes to it. Check the Mode.

This is a modified version of my previous homemade CNC machine. Instead of using threaded rods this one uses (GT2) belts and has a larger working area of 50x70 cm or 20x27 inch. By using belts it's also faster. This is the third version of my DIY homemade CNC machine. Instead of using threaded rods I’m now using (GT2) belts and it has a larger working area of 50×70 cm or 20×27 inch. By using belts it’s also faster. To get a better understanding of the machine, also check the previous version here:

mostly 3d printed cnc

convert 3d printer to cnc

best 3d printer for cnc

Since a musty smell is often the result of mold, you should check that you aren't suffering from a plumbing leak from your kitchen sink. Quick and Dirty Tips suggests turning off your water.

3d printed cnc machine v3|convert 3d printer to cnc