applying forming tools to sheet metal parts Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part. Create modern double shelves with our Heavy Duty U Shaped Brackets - many sizes and colors for custom shelving. Easy to install and Made in USA. Shop Now!

0 · solidworks sheet metal stamping

1 · sheet metal forming solidworks

2 · sheet metal forming hand tools

3 · sheet metal forming by hand

4 · sheet metal fabricating tools

5 · forming tool sheet metal solidworks

6 · custom tooling for metal forming

7 · custom sheet metal forming

Keep your supplies and ammunition safe, dry, and secure in any of the authentic military-grade metal ammo storage available from Army Surplus World! Our extensive selection includes a wide range of sizes, colors, and calibers to suit your every storage need.

solidworks sheet metal stamping

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.Sheet metal parts display the Sheet-Metal feature in the FeatureManager design .Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet .Applying Forming Tools to Sheet Metal Parts. Forming tools from the Design .

Forming tools from the Design Library are used only with sheet metal parts. Sheet .Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The .Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The .

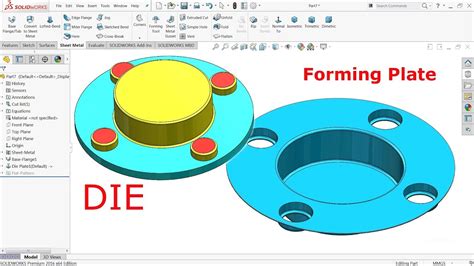

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes . This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a . This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a . Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such .

Essential sheet metal forming techniques such as bending, curling and ironing are used to transform flat sheets into intricately shaped components. Advanced tools and technologies in sheet metal forming provide increased .Applying Forming Tools to Sheet Metal Parts. Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the .Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree.

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.

Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes some sample forming tool parts to get you started.

This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video will help you master sheet metal design using SolidWorks, covering essential techniques and tips to boost your productivity.

This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video will help you master sheet metal design using SolidWorks, covering essential techniques and tips to boost your productivity. Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such as bending, hydroforming, stretching, punching, and deep drawing to create sophisticated parts with high precision. Essential sheet metal forming techniques such as bending, curling and ironing are used to transform flat sheets into intricately shaped components. Advanced tools and technologies in sheet metal forming provide increased productivity, cost efficiency, flexibility & .Applying Forming Tools to Sheet Metal Parts. Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of .

Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree.

sheet metal forming solidworks

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.

Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of the maximum thickness for a sheet metal part.Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. The SOLIDWORKS software includes some sample forming tool parts to get you started. This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video will help you master sheet metal design using SolidWorks, covering essential techniques and tips to boost your productivity. This tutorial provides a step-by-step guide on applying forming tools to design intricate shapes, bends, and cuts commonly used in manufacturing. Whether a beginner or a professional, this video will help you master sheet metal design using SolidWorks, covering essential techniques and tips to boost your productivity.

Sheet metal forming is a flexible metal deformation process to shape thin-level metal sheets into desired shapes. The process is relatively cost-effective and ideal for large parts volume. It utilizes multiple approaches such as bending, hydroforming, stretching, punching, and deep drawing to create sophisticated parts with high precision. Essential sheet metal forming techniques such as bending, curling and ironing are used to transform flat sheets into intricately shaped components. Advanced tools and technologies in sheet metal forming provide increased productivity, cost efficiency, flexibility & .Applying Forming Tools to Sheet Metal Parts. Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. You must consider how the minimum radius of curvature (MRC) correlates with the forming tool. The MRC in a forming tool is a good measure of .

how to attach raco electrica box to wall

「NEMA 6 Rated」- This Type 6 NEMA weatherproof enclosure is perfect for both indoor and outdoor use. It provides protection against dust, rain, snow, sun, corrosion, and even temporary water submersion, ensuring your electrical .

applying forming tools to sheet metal parts|sheet metal forming solidworks