titanium alloy cnc machining parts We are experienced in custom machining Titanium parts for industries such as medical and aerospace. We can help with your Swiss Screw Machining and CNC Milling needs! CNC turning, milling, conventional machining, and wire EDM capabilities, contact Small Parts Vietnam today at

[email protected]. Our team of skilled and tenured craftsmen is ready to work with you to design and manufacture the parts you need at a competitive price with uncompromising quality.

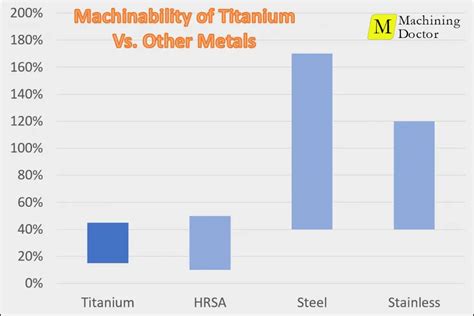

0 · titanium machinability chart

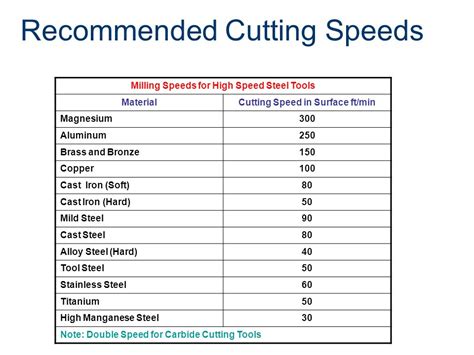

1 · recommended cutting speeds for titanium

2 · machining titanium without coolant

3 · is titanium hard to cut

4 · is titanium difficult to machine

5 · does titanium bend when machining

6 · best way to cut titanium

7 · best end mill for titanium

ITT Cannon CT series heavy duty 5015 connectors were originally designed as aerospace components and are popular, cost-effective, rugged commercial and military connectors. Type: MS. Housing Gender: Receptacle.

RAM Tool provides industry-leading CNC machining services for custom parts made from titanium alloys. Our job shop specializes in manufacturing some of the most complex and intricate .

We are experienced in custom machining Titanium parts for industries such as medical and aerospace. We can help with your Swiss Screw Machining and CNC Milling needs! PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die .DEZE offers comprehensive titanium machining services, utilizing advanced techniques such as CNC turning, milling, drilling, grinding, water jet cutting, laser cutting, plasma cutting, and EDM. DEZE is a leading and dedicated manufacturer of high-precision Ti parts, capable of processing various grades of Ti, including Grade 1, Grade 2, and .Titanium is widely used in aerospace, medical devices, and automotive parts. CNC machining is ideal for complex titanium alloy parts. Skip to content [email protected] +86 13342948130; . Classification of Grades for CNC Machining of Titanium Alloys. Because of the different alloy components, the mechanical properties of titanium alloys will .

This quality makes it perfect for CNC machining titanium parts where robustness yet lightness is crucial. Highly Durable: . Known as the “workhorse” of the aerospace industry, this alloy handles high temperatures and is used in aircraft turbines and structural components. It is also important in sports equipment and biomedical implants. TC6 titanium alloy is a martensitic α-β two-phase titanium alloy with good comprehensive performance. Its nominal composition is Ti-6Al-2.5Mo-1.5Cr 0.5Fe-0.3Si. It has high room temperature strength. The chemical composition is shown in Table 1. It can work for more than 6000 hours at below 400℃ and 2000 hours at below 450℃. table1 1 2.

titanium machinability chart

Since 1958, Forster Tool has been providing custom machined titanium parts. Usage of Titanium and its alloys is increasing, especially in the aerospace and biomedical applications. Custom Machined parts made from titanium presents unique challenges that require experienced machinists to assure get the best results when machining titanium.Here is how to choose the right cutting tool for milling titanium alloy or using other CNC machining techniques. 1) Consider the number of cutting edges of the cutting tool. . 6.Surface treatment of cnc machining titanium parts. A range of surface treatment techniques, including titanium polishing, can enhance the functionality and aesthetics .We work with one of the industry’s most diverse ranges of commercially pure and titanium-based alloy CNC machining materials, including those that many other companies are unable to source or unwilling to machine. . We have the equipment and experience to produce CNC-machined titanium parts of a wide range of sizes, from parts small enough .

Common Uses of Titanium Alloy Machining. Titanium machining finds application across diverse industries: Aerospace: Used for aircraft components such as engine parts, landing gear, and structural components due to its strength-to-weight ratio.; Medical: Essential for manufacturing surgical implants and instruments due to its biocompatibility and corrosion . TC4 titanium is characterized by low specific gravity, high strength, high temperature, and corrosion resistance. It is a difficult-to-machine material. TC4 titanium alloys are commonly machined with carbide tools, and the material and quality of the tools are critical. However, to produce high-quality parts, in addition to having precision ultra-precision machine tools and .An alloy with a host of unique properties, titanium is often an optimal choice for CNC machined parts with specialized applications. Titanium has an impressive strength-to-weight ratio and is 40% lighter than steel while being only 5% weaker.Titanium alloy CNC machining should choose lower cutting speed, appropriately large feed rate, reasonable depth of cut and finishing amount, and sufficient cooling.. Cutting speed Vc: Vc=30~50m/min. Feed rate: Take a larger feed rate for rough machining, and a moderate feed rate for finishing and semi-finishing.. Cutting depth ap: ap=1/3d is appropriate, titanium alloy .

Advantages and Applications for CNC Machining Titanium. CNC-machined titanium parts are exceptionally durable and titanium’s high strength-to-weight ratio, biocompatibility, and chemical/corrosion resistance make it an attractive material for the following applications. Aerospace is the primary consumer of titanium materials. Applications .

CNC Machining; Injection Molding; 3D Printing; Materials; . Service Overview. Custom Titanium Parts. eMachineShop has machined titanium parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. . Alloy Ti6Al4V / Ti-6AL-4V / Ti 6-4 The most commonly used titanium .Titanium CNC machining. An alloy with a host of unique properties, titanium is often an optimal choice for CNC machined parts with specialized applications. Titanium has an impressive strength-to-weight ratio and is 40% lighter than .Hudson Manufacturing is the leading manufacturer of customized CNC machining parts with more than 12 years experience in Dongguan, Gaungdong, China. Read More. 10 Mins quote Fast 3 Days Sampling 12 . Fabrication Service CNC Machining Aluminum Stainless Steel Brass Titanium Alloy Metal Parts for Media Medical Parts.The Key Benefits of CNC Machined Titanium Parts. Titanium’s appeal lies in a set of characteristics that make it incredibly unique. Strength and Lightweight: . Popular Titanium Alloys for CNC Machining. Titanium alloys are especially .

Nanjing Morong Machinery Technology Co., Ltd.: We're well-known as one of the leading CNC machining parts, bicycle frame building parts, brake parts, dropouts, stem parts enterprises in China. If you're going to buy high quality customized products with competitive price, welcome to get more information from our factory.Titanium CNC machining is a specialized manufacturing process used to create high-precision parts from titanium alloys. Known for its strength, durability, and corrosion resistance, titanium is widely used in industries such as aerospace, medical, automotive, and marine.

GD prototyping We provide precision CNC machining services,titanium alloy cnc machining partsWelcome to CDX Established since 2007,CDX is a professional manufacturer & supplier for custom precision Machining parts, we specialize in CNC Machining, CNC turning,Automatic lathe turning, Stamping, Sheet metal fabrication, Casting, etc. . The Introduction To Turning Of Titanium Alloy Parts. The Introduction to Turning of Titanium Alloy . Titanium is an exceptional material for CNC machining, known for its ability to withstand high temperatures and resist chemical corrosion. Additionally, its lightweight nature and various other qualities make it highly sought after by manufacturers. While CNC machined titanium parts are incredibly durable, machining titanium can be challenging due to its high .We are able to process high Titanium Parts CNC machining with stable and reliable quality. Advanced equipment ensures high and consistent quality, with tolerance down to +/-0.01mm . TC4 titanium alloy has excellent corrosion resistance, small density, high specific strength, and better toughness and weldability, and a series of advantages, in .

Grade 5 Titanium, or Ti6Al4V, is a popular titanium alloy for CNC machining due to its exceptional combination of properties. With 6% aluminum, 4% vanadium, and 90% titanium, it has a density of 4.43 g/cm³ and a tensile strength of 880 MPa, making it one of .

Explore different types of cnc titanium machining parts here. Sibai did a lot of big frames and structure for big machines and equipments, from casting, CNC machining, and surface treatment. Sibai provides many kinds of housings for outdoor fences. . Titanium Alloy, TC4, TC2: Processing: CNC turning, CNC machining, milling, grinding: Researchers from the Royal Melbourne Institute of Technology (RMIT University) in Australia, in collaboration with the Czech group Tescan and the University of North Texas in the United States, have developed a new bainitic titanium alloy (Ti-Cu-Fe). This advancement is expected to significantly improve the quality and performance of parts.

2.Commonly used lightweight metals for CNC machining (i)Aluminum alloy. . Titanium has a strength of more than 1000MPa, which is several times that of ordinary steel. Titanium parts perform reliably under high loads, ensuring product safety. Features. Features: Density 4.43 g/cm³, high tensile strength, excellent corrosion resistance .

recommended cutting speeds for titanium

$35.00

titanium alloy cnc machining parts|best way to cut titanium