diy laser cnc machine In this chapter, we will guide you through the process of designing your DIY Laser CNC machine. We'll discuss the considerations for the machine's dimensions, stability, and ergonomics. We . The setback chart is a quick way to find the setback and is useful for open and closed bends, because there is no need to calculate or find the K-factor. Several software packages and .

0 · make your own laser engraver

1 · diy rotary laser engraver

2 · convert laser engraver to cnc

3 · build your own laser engraver

4 · build your own laser cutter

5 · build your own handheld laser

6 · best neje laser diy engraver

7 · best diy laser engraving machine

Multi-chapter guide to Metal Mesh describing: the types, applications, materials, weave patterns, benefits and applications of metal mesh.

make your own laser engraver

As the name suggests, a DIY laser cutter is a CNC machinethat you build yourself, rather than buying a preassembled, ready-to-use machine. DIY laser cutters can be unassembled kits . See more

diy rotary laser engraver

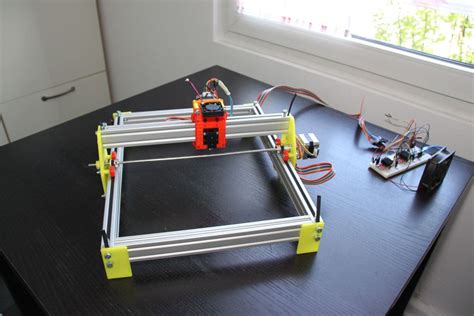

The brain of this CNC machine is and Arduino UNO board in combination with a CNC shield, but more details about that as well as how to prepare your drawings or images for laser engraving, make G-codes .In this chapter, we will guide you through the process of designing your DIY Laser CNC machine. We'll discuss the considerations for the machine's dimensions, stability, and ergonomics. We .

Homemade 3 in 1 CNC (Router, 3D Printer & Laser Engraver): This is by far the most longest-running build I have ever made and some improvement always . Install Raid for Free IOS/ANDROID/PC: https://clcr.me/nsSoGZ and get a special starter pack 💥 Available only for the next 30 daysCode, 3D model, parts lis.I've included every file you need for building it in this instructable. This lasercutter uses a 40 W CO2 laser, has a large cutting area of 1000 by 600 mm and has a touchscreen to control it! The entire project cost me about €1900, this is still a .

In this DIY tutorial, I will go through everything about building this project, Circuit diagram and all the instructions to set up and run this machine. Thank You NextPCB: This project was successfully completed because of the help and .

Are you planning to build your own laser cutting machine for hobbyists, or commercial use to make money with it? Review this guide on how to DIY a laser cutter. I built my own DIY CNC machine from scratch, welding metals to make a rigid CNC body, and making CNC control systems for powerful motors. I gained unique experiences both building and working with that CNC machine, .

convert laser engraver to cnc

build your own laser engraver

cnc router parts electrical enclosure

As the name suggests, a DIY laser cutter is a CNC machine that you build yourself, rather than buying a preassembled, ready-to-use machine. DIY laser cutters can be unassembled kits that you order online and then put together yourself, or they can be built completely from scratch by sourcing each individual part separately.

The brain of this CNC machine is and Arduino UNO board in combination with a CNC shield, but more details about that as well as how to prepare your drawings or images for laser engraving, make G-codes and control the machine using free, open-source programs, a bit later in the video.

The best DIY CNC routers give you access to repeatable precision and reliability for your projects – without paying thousands of dollars for professional machines. My top choice for beginners is the Sainsmart Genmitsu 3018 PRO .In this chapter, we will guide you through the process of designing your DIY Laser CNC machine. We'll discuss the considerations for the machine's dimensions, stability, and ergonomics. We will also provide step-by-step instructions on creating the design using CAD software, allowing you to visualize the machine before construction.

Homemade 3 in 1 CNC (Router, 3D Printer & Laser Engraver): This is by far the most longest-running build I have ever made and some improvement always left here and there. But overall said that the machine is running fine without giving any trouble.Install Raid for Free IOS/ANDROID/PC: https://clcr.me/nsSoGZ and get a special starter pack 💥 Available only for the next 30 daysCode, 3D model, parts lis.

I've included every file you need for building it in this instructable. This lasercutter uses a 40 W CO2 laser, has a large cutting area of 1000 by 600 mm and has a touchscreen to control it! The entire project cost me about €1900, this is still a lot of money, but I .In this DIY tutorial, I will go through everything about building this project, Circuit diagram and all the instructions to set up and run this machine. Thank You NextPCB: This project was successfully completed because of the help and support from NextPCB. Are you planning to build your own laser cutting machine for hobbyists, or commercial use to make money with it? Review this guide on how to DIY a laser cutter.

I built my own DIY CNC machine from scratch, welding metals to make a rigid CNC body, and making CNC control systems for powerful motors. I gained unique experiences both building and working with that CNC machine, and I’ve also published brand-new research on how to cheaply cut granite and stone with a unique trick (check my guide for this). As the name suggests, a DIY laser cutter is a CNC machine that you build yourself, rather than buying a preassembled, ready-to-use machine. DIY laser cutters can be unassembled kits that you order online and then put together yourself, or they can be built completely from scratch by sourcing each individual part separately.The brain of this CNC machine is and Arduino UNO board in combination with a CNC shield, but more details about that as well as how to prepare your drawings or images for laser engraving, make G-codes and control the machine using free, open-source programs, a bit later in the video.

The best DIY CNC routers give you access to repeatable precision and reliability for your projects – without paying thousands of dollars for professional machines. My top choice for beginners is the Sainsmart Genmitsu 3018 PRO .In this chapter, we will guide you through the process of designing your DIY Laser CNC machine. We'll discuss the considerations for the machine's dimensions, stability, and ergonomics. We will also provide step-by-step instructions on creating the design using CAD software, allowing you to visualize the machine before construction.Homemade 3 in 1 CNC (Router, 3D Printer & Laser Engraver): This is by far the most longest-running build I have ever made and some improvement always left here and there. But overall said that the machine is running fine without giving any trouble.

Install Raid for Free IOS/ANDROID/PC: https://clcr.me/nsSoGZ and get a special starter pack 💥 Available only for the next 30 daysCode, 3D model, parts lis.

I've included every file you need for building it in this instructable. This lasercutter uses a 40 W CO2 laser, has a large cutting area of 1000 by 600 mm and has a touchscreen to control it! The entire project cost me about €1900, this is still a lot of money, but I .

In this DIY tutorial, I will go through everything about building this project, Circuit diagram and all the instructions to set up and run this machine. Thank You NextPCB: This project was successfully completed because of the help and support from NextPCB. Are you planning to build your own laser cutting machine for hobbyists, or commercial use to make money with it? Review this guide on how to DIY a laser cutter.

build your own laser cutter

build your own handheld laser

Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common throughout various industries, including manufacturing, construction, automotive, and aerospace. Learn more about the process below.

diy laser cnc machine|best neje laser diy engraver