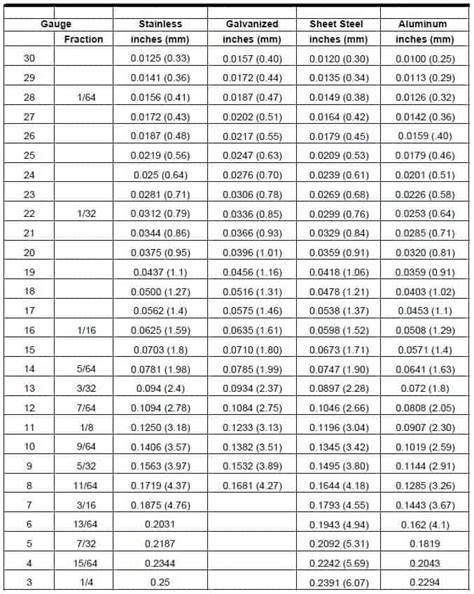

crs sheet metal thickness Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below. Or you can Download the Sheet Metal Gauge Size Chart PDF. (Click here) . Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

0 · steel sheet mechanical tolerances chart

1 · steel gauge thickness chart

2 · standard sheet metal gauge size chart

3 · sheet metal gauge thickness chart

4 · cold rolled steel sheets

5 · cold rolled carbon steel sheets

6 · astm steel sheet tolerance chart

7 · a1008 carbon steel sheet

Still, it’s possible to weld thin sheet metal using the MIG (GMAW), TIG (GTAW), and stick (SMAW) processes. But MIG and TIG provide the best results. This article will teach you how to weld thin gauge metal using each arc welding process and present the common pitfalls beginners make.

steel sheet mechanical tolerances chart

Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below. Or you can Download the Sheet Metal Gauge Size Chart PDF. (Click here) .Galvanized Steel Coil & Sheet; Galvalume Steel Coil & Sheet; Corrugated Steel .A1008 (AISI 1008) cold rolled (CR) steel sheet exhibits improved formability over hot rolled sheet. ASTM A1008 CR is produced by annealing and temper rolling hot rolled steel sheets. This process provides formability, improved surface .

The chart below can be used to determine the equivalent sheet thickness, in inches .

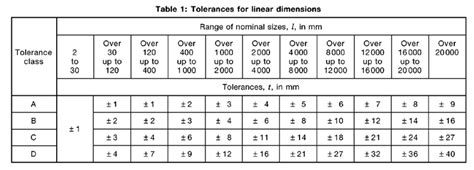

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .

Mead Metals is an industry-leading provider of cold rolled carbon steel. We keep 1008 steel and 1010 steel available in thicknesses from 0.005 to 0.134, in commercial quality through full-hard tempers. Mead Metals Inc. carries cold .Steel is ideal for general-purpose sheet-metal or machined parts. Protocase recommends cold rolled steel for general purpose enclosures. It offers a good combination of cost and structural integrity (stiffness). If corrosion resistance is .The normal sheet metal gauge range starts at 30 on the thin end and descends to 7 on the thick end. However, the exact thickness and gauge will vary based on the type of metal. Many metals may be manufactured in gauges as high as 36 .

16 gauge aluminum is 0.062” thick, whereas 16 gauge steel is actually 0.059” thick. The 0.003” difference in thickness may not seem significant, but depending on your design, that variation can cause big problems in your .

Cold rolled steel is sold in many thicknesses identified by the gauge (GA) standard. The smaller the gauge the thicker the sheet. The table below lists the most common range of CRS we use. Hot rolled steel (HRS) is steel that has .A sheet metal gauge (sometimes spelled "gage") indicates the standard thickness of sheet metal for a specific material. As the gauge number increases, the material thickness decreases. .

Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below. Or you can Download the Sheet Metal Gauge .A1008 (AISI 1008) cold rolled (CR) steel sheet exhibits improved formability over hot rolled sheet. ASTM A1008 CR is produced by annealing and temper rolling hot rolled steel sheets. This process provides formability, improved surface texture and flatness.The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.

Mead Metals is an industry-leading provider of cold rolled carbon steel. We keep 1008 steel and 1010 steel available in thicknesses from 0.005 to 0.134, in commercial quality through full-hard tempers. Mead Metals Inc. carries cold rolled steel per ASTM A1008 and AISI 1008/1010 grades.Steel is ideal for general-purpose sheet-metal or machined parts. Protocase recommends cold rolled steel for general purpose enclosures. It offers a good combination of cost and structural integrity (stiffness). If corrosion resistance is required, consider .

steel gauge thickness chart

The normal sheet metal gauge range starts at 30 on the thin end and descends to 7 on the thick end. However, the exact thickness and gauge will vary based on the type of metal. Many metals may be manufactured in gauges as high as 36 or as low as 3, well above the typical range. 16 gauge aluminum is 0.062” thick, whereas 16 gauge steel is actually 0.059” thick. The 0.003” difference in thickness may not seem significant, but depending on your design, that variation can cause big problems in your final product.Cold rolled steel is sold in many thicknesses identified by the gauge (GA) standard. The smaller the gauge the thicker the sheet. The table below lists the most common range of CRS we use. Hot rolled steel (HRS) is steel that has been formed at high temperature.A sheet metal gauge (sometimes spelled "gage") indicates the standard thickness of sheet metal for a specific material. As the gauge number increases, the material thickness decreases. Sheet metal thickness gauges for steel are based on a weight of .

Even when the non-ferrous metal plate and the steel plate are the same Ga., the thickness is actually different. You can find the gauge to mm / inch conversion for sheet metal by the chart below. Or you can Download the Sheet Metal Gauge .

A1008 (AISI 1008) cold rolled (CR) steel sheet exhibits improved formability over hot rolled sheet. ASTM A1008 CR is produced by annealing and temper rolling hot rolled steel sheets. This process provides formability, improved surface texture and flatness.The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.Mead Metals is an industry-leading provider of cold rolled carbon steel. We keep 1008 steel and 1010 steel available in thicknesses from 0.005 to 0.134, in commercial quality through full-hard tempers. Mead Metals Inc. carries cold rolled steel per ASTM A1008 and AISI 1008/1010 grades.

Steel is ideal for general-purpose sheet-metal or machined parts. Protocase recommends cold rolled steel for general purpose enclosures. It offers a good combination of cost and structural integrity (stiffness). If corrosion resistance is required, consider .The normal sheet metal gauge range starts at 30 on the thin end and descends to 7 on the thick end. However, the exact thickness and gauge will vary based on the type of metal. Many metals may be manufactured in gauges as high as 36 or as low as 3, well above the typical range.

16 gauge aluminum is 0.062” thick, whereas 16 gauge steel is actually 0.059” thick. The 0.003” difference in thickness may not seem significant, but depending on your design, that variation can cause big problems in your final product.Cold rolled steel is sold in many thicknesses identified by the gauge (GA) standard. The smaller the gauge the thicker the sheet. The table below lists the most common range of CRS we use. Hot rolled steel (HRS) is steel that has been formed at high temperature.

You may need to adjust the geometry of the shelf to accommodate the added thickness of the hinge. The door tab will fit flush with the rear of the chimney between the rear legs. Simply tack this hinge in place. Start your tack on the thicker steel and drag the puddle over the thinner metal to avoid blowouts.

crs sheet metal thickness|cold rolled steel sheets