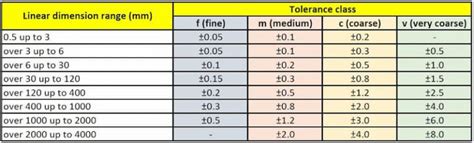

cnc machine tolerance chart ISO 2768 Part 1 categorizes tolerances into four classes based on precision requirements: fine (f), medium (m), coarse (c), and very coarse (v). These classifications help in setting appropriate limits for various . The Scoutmaster was standard with a VPI JMW 9 arm but would have the option to upgrade to the Nordost Valhalla wire. The easiest way to tell if your Scoutmaster has a signature arm is to see what color the wire is connecting to your junction box.

0 · standard tolerance chart for machining

1 · milling tolerance chart

2 · machinist tolerance chart

3 · machining tolerances chart

4 · how accurate are cnc machines

5 · cnc tolerance chart

6 · cnc machining tolerance chart

7 · cnc machine tolerance standards

Recently introduced rechargeable hearing aids are made out of lithium-ion batteries that do contain lithium. These should not be confused with traditional disposable zinc-air batteries that do not contain lithium. Lithium batteries are considered safe .

standard tolerance chart for machining

Read about the recommendations for CNC machining tolerances and what to consider when deciding on the tolerance ranges.

milling tolerance chart

The figure presented in the machining tolerance chart demonstrates the general linear tolerance and the general angular tolerance of the ISO 2768-1 standard.ISO 2768-1: Controls linear and angular dimensions through four tolerance classes based on the ISO tolerance chart: Fine tolerance (f) Medium ISO (m) / ISO 2768 mittel. Coarse (c) Very .

Machining tolerance is the value limit till which variation in a dimension can be allowed in relation to its ideal blueprint values. Machining tolerances depict the accuracy of . ISO 2768 Part 1 categorizes tolerances into four classes based on precision requirements: fine (f), medium (m), coarse (c), and very coarse (v). These classifications help in setting appropriate limits for various .Tolerances are crucial in CNC machining for several reasons: Ensuring Fit and Functionality: Proper tolerances ensure that parts fit together as intended and function correctly. Quality Control: Tolerances help maintain consistent quality .

In precision CNC machining, dimensional tolerance plays a crucial role in ensuring the accuracy and functionality of machined parts. ISO 2768 is an international standard that provides guidelines for general tolerances of linear .

What is CNC Machining Tolerance? Importance of Knowing CNC Machining Tolerance. Common Terms When Expressing CNC Tolerance in Machining Operations. Key Takeaways. Understanding CNC machining tolerance and its relation with the manufacturing process. In-depth analysis of different types of tolerances, namely general, unilateral, bilateral, .

machinist tolerance chart

machining tolerances chart

stainless steel kitchen cabinet price philippines

Tolerance in machining involves both desing tolerance and the accuracy of the CNC machine l. The Desing tolerance refers to the allowable deviation range in the dimension specified in the CAD model. For example, 20±0.5 mm means if the manufactured dimensions fall under 19.5 to 20.5, it does not affect the intended fit in assembly or performances.

Thus only standard machining tolerance of CNC machine does not decide the fate of final job. CNC Machining Tolerance . . CNC Lathe Tolerances Chart . In this machining operation machining pattern has some limitation due to moving workpiece and stationary tool, thus there is less chance of deviation in dimension of machining. .

What is a tight tolerance CNC machining? Although there is no specific range of tight tolerances in CNC machining, any tolerance within the range of ±0.005” is regarded as a tight tolerance. However, tight limit tolerance . Machining tolerance range is the key elements of used to judge the machined parts quality. For different work-piece, tolerance requirement are different, in order to avoid machining failure, machining tolerance table is used to specified normal machining accuracy class. MACHINING TOLERANCE TABLE Free tolerance table of machining 1.

Here we introduce ISO 2768 standard and ISO 2768 tolerance chart, also provide a free PDF file of General Tolerances for Linear and Angular Dimensions for download. . The Standard Tolerances For CNC Machining List of Drill Bit and Tap Sizes – Drill Size Chart and Tap Size Chart | CNCLATHING Metal Gauge Chart for Steel, Stainless, . 5. Limit Tolerances. A limit tolerance is expressed as a range of values, where the part is fine as long as the measurement falls between that range. 13 – 13.5mm for example is a limit tolerance for CNC machining indicating that the part must have a measurement that falls between the upper and the lower limit (13mm is the upper limit and 13.5mm is the lower limit).

The general tolerance for roundness for cylindricity is not specified. The general tolerance for parallelism is equal to the numerical value of the dimensional tolerance or the flatness or straightness tolerance, whichever is larger. Table 2.1 General Tolerances on Straightness and Flatness Permissible deviations in mm for ranges in nominal lengths Types of tolerances in CNC Machining . Unilateral Tolerance. Unilateral tolerance is one of the specific types of machining tolerances that plays an essential role in CNC manufacturing. Unlike other tolerances, unilateral tolerance defines a permissible variation in only one direction from the nominal size of the part.. In unilateral tolerance, the allowable deviation .Understanding the CNC machining tolerance chart and adhering to tight tolerance machining practices are vital for ensuring high-quality outcomes. Tolerance in machine design, along with compliance with CNC tolerance standards, ensures the proper fit and functionality of machined parts. High tolerance machining requires meticulous attention to .

This CNC Tolerances Chart provides a clear breakdown of allowable dimensional variations based on the size of the component and the required precision level. The chart categorizes tolerances into four levels: Fine (F), Medium (M), Coarse (C), and Very Coarse (V), corresponding to different linear dimension ranges.Tolerancing Guidelines for CNC Machining. Also, be aware that these are bilateral tolerances. If expressed in unilateral terms, the standard tolerance would read +0.000/- 0.010 in. (or +0.010/- 0.000 in.) while a limit-based tolerance in our bracket example would be 1.005 / 0.995 in.. All are acceptable, as are metric values, provided that you spell them out on the design. CNC Machining Tolerance Chart & Specifications. Here below are the tolerance standard for the different tolerances. Tolerance Chart: ISO 286: ISO 286 is an international standard that defines tolerances and fits for ISO metric threads and hole and shaft systems. It ensures proper mating of mechanical parts and interchangeability.

ISO 2768 is widely used in various industries, including CNC machining, to ensure consistent interpretation and application of tolerances. It is also available as a DIN standard in Germany. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions .Size limit charts for H & h devaitions (Metric and Inch) according to ISO 286-1:2010. . Machining DataSheets; Carbide Grades Chart; Specific Cutting Force (KC) Charts; More Charts Menu Toggle. Engineering Fits & Tolerances; SFM .An Overview of CNC Machining Tolerance Chart\ A. Understanding the different types of tolerances specified in the chart\ B. Exploring the relationship between tolerance and feature size\ C. Interpreting the symbols and abbreviations used in the tolerance chart . III. Factors Affecting CNC Machining Tolerance\

Size limit charts for M & m devaitions (Metric and Inch) according to ISO 286-1:2010. . Machining DataSheets; Carbide Grades Chart; Specific Cutting Force (KC) Charts; More Charts Menu Toggle. Engineering Fits & Tolerances; SFM .

Machine tolerances: Depending on the type of CNC machine, they also have their own restriction and range of achievable accuracy while machining. Generally, CNC machines are capable of maintaining a tolerance of ± 0.0025mm(Fan J, 2021) Tolerancing is crucial when parts are assembled later to make a specific product.

CNC Milling Machines. Table Top Milling Machines At CNC Masters, we offer a range of outstanding table top milling machines. Each of these compact CNC mills is designed to pack maximum power into a small footprint, all while remaining affordable. . Beyond enhancing product integrity, a strict tolerance CNC machining process brings efficiency .If your project requires the fabrication of a precise metal part with tight tolerances, CNC machining is an excellent option to consider. CNC machines are known for their high precision and can create parts with very tight tolerances. Typically, the tolerance range in CNC machining can vary from ±0.001″ to ±0.0001″.

How Well Does CNC Machining Perform? CNC machining is one of the most popular manufacturing processes today. And this is primarily due to its high accuracy, precision, and tight tolerance range. In fact, with CNC machining, you can accurately create over 1000 units of identical parts while achieving tolerances as small as ±0.04 mm. Laser Cutting Tolerance Chart. Laser cutting tolerance can vary depending on several factors, including the type of machine used, the nature of the material being cut, the thickness of the material, and the quality of the laser beam. Here is a general guideline for laser cutting tolerances. The table below details the ISO 2768 tolerances for angular dimensions, expressed in degrees and minutes. These tolerances apply to the shorter leg of an angle and are categorized by Fine (f) and Medium (m) tolerance classes. . ISO 286 is a standard commonly applied to subtractive manufacturing methods, such as CNC machining, to define .

1. What is Meant by Tolerance in CNC Machining? How the Concept of Tolerance Has emerged from CNC Machining. For starters, CNC machining is the process of manufacturing a part of a raw workpiece. It is done by automated equipment units and cutting tools that follow the programmed path. It is how a particular shape or design can be obtained. CNC Machining Tolerance Chart. The following symbols are used for specifying geometrical characteristics on engineering drawings. This geometric tolerancing chart is based on the ASME Y14.5: Why It’s Important To Understand Machining Tolerances. The Significance of ISO 2768 Dimensional Tolerance Chart . In precision CNC machining, dimensional tolerance plays a crucial role in ensuring the accuracy and functionality of machined parts. ISO 2768 is an international standard that provides guidelines for general tolerances of linear and angular dimensions without individual tolerance .Table of Contents Overview What is CNC machining? CNC Milling Machines CNC Lathes CNC Manufacturing Standards General Manufacturing Standards General Tolerances . General tolerances for CNC machining are typically starting at ± 0.1 mm. Tight tolerances typically describe tolerances smaller than the general standard. With CNC machining, we can

how accurate are cnc machines

cnc tolerance chart

Metal, wood (or plaster), and leather strap wand/gun-shaped thing. Found in the front yard, I guess it was dropped by accident? Weighs just under 1.5 lbs and .

cnc machine tolerance chart|cnc tolerance chart