common sheet metal process The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In . When it comes to completing electrical projects, a 4-way junction box can be a powerful tool. Not only does it provide a safe and secure way to route electrical power throughout a home or commercial property, but it also ensures that the .

0 · various sheet metal processes

1 · types of sheet metal process

2 · sheet metal working process pdf

3 · sheet metal processes pdf

4 · sheet metal process in manufacturing

5 · sheet metal operations with diagrams

6 · sheet metal forming process pdf

7 · sheet metal fabrication pdf

Find the best selection of PSWY Bed Frames and other Beds & Headboards on Wayfair Canada to match your preferred style and budget. Enjoy Free Shipping on most PSWY Bed Frames orders over CAD $50! . Metal. Fabric. Plastic. Filter By Colour. White. Black. Beige. Grey. Brown. Pink. Natural. . Solid Wood Platform Pine Bed With Wooden Slats No .

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In .

Sheet metal fabrication is a versatile manufacturing process with an extensive list of techniques and usable metals. Getting familiar with the technology, how it works, and its applications will help you decide if it is the .

various sheet metal processes

types of sheet metal process

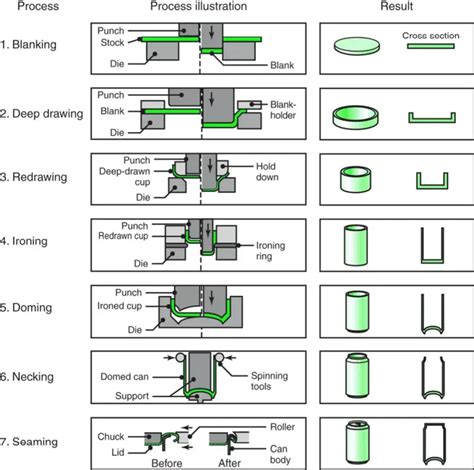

Sheet metal fabrication is a set of manufacturing processes for turning sheet metal into functional parts. For this guide, we have divided the processes into three categories: . However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what . Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost .In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling.

Below, we’ll explain the most common metal manufacturing processes: The first step in the sheet metal fabrication process is cutting, which is where the fabricators will slice the raw materials .Sheet metal fabrication involves slicing, punching, bending, and assembling flat steel or aluminium sheets into metal structures or items. Cutting and burning sheet metal into almost any form allows the machine to slice, fold, or stretch it .Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms.

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In this article, we’ll explore the nine vital steps in sheet metal fabrication, providing valuable insights for businesses and industry professionals. Sheet metal fabrication is a versatile manufacturing process with an extensive list of techniques and usable metals. Getting familiar with the technology, how it works, and its applications will help you decide if it is the best option for your project. Sheet metal fabrication is a set of manufacturing processes for turning sheet metal into functional parts. For this guide, we have divided the processes into three categories: cutting, deformation, and assembly.

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve. Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control.In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling.

Below, we’ll explain the most common metal manufacturing processes: The first step in the sheet metal fabrication process is cutting, which is where the fabricators will slice the raw materials into the parts needed to complete a project. Getting precise cuts is critical.Sheet metal fabrication involves slicing, punching, bending, and assembling flat steel or aluminium sheets into metal structures or items. Cutting and burning sheet metal into almost any form allows the machine to slice, fold, or stretch it into virtually any shape.Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. What is the Sheet Metal Process? The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form and cut sheets into the necessary shapes and forms.

sheet metal working process pdf

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In this article, we’ll explore the nine vital steps in sheet metal fabrication, providing valuable insights for businesses and industry professionals. Sheet metal fabrication is a versatile manufacturing process with an extensive list of techniques and usable metals. Getting familiar with the technology, how it works, and its applications will help you decide if it is the best option for your project. Sheet metal fabrication is a set of manufacturing processes for turning sheet metal into functional parts. For this guide, we have divided the processes into three categories: cutting, deformation, and assembly. However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve.

Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control.In this blog, we dive into seven key sheet metal forming processes that shape modern manufacturing: Laser Cutting, Water Jet Cutting, Stamping, Welding, Roll Forming, Spinning, and Rolling.

Below, we’ll explain the most common metal manufacturing processes: The first step in the sheet metal fabrication process is cutting, which is where the fabricators will slice the raw materials into the parts needed to complete a project. Getting precise cuts is critical.

sheet metal processes pdf

sheet metal process in manufacturing

sheet metal operations with diagrams

sheet metal forming process pdf

We service both steep and flat roofs and work with a wide variety of roofing materials, including EPDM, TPO, PVC, shingles, slate, tile, and others. For a free estimate on any of our roofing services, please contact us today.

common sheet metal process|various sheet metal processes