roll sheet metal solidworks To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, . Browse our extensive inventory of new and used salt spreaders from local dealers and private sellers. Compare prices, models, trims, options and specifications .

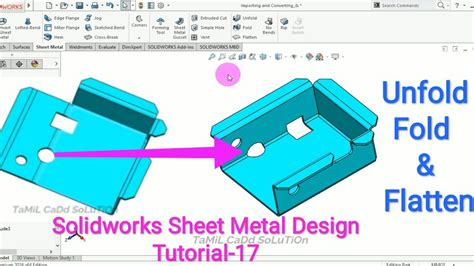

0 · solidworks unfold sheet metal

1 · solidworks unbend sheet metal

2 · solidworks sheet metal pdf

3 · solidworks sheet metal examples

4 · solidworks sheet metal drawing pdf

5 · solidworks sheet metal cylinder

6 · sheet metal modeling in solidworks

7 · folding sheet metal in solidworks

Another option is to install NMD90 in the interior of the house, install a junction box ( that will be assessable) that has a connection to the outdoor conduit, then splice the NMD90 to RW90. The RW90 would then .

How to create a simple rolled sheetmetal part.

how to replace an electric meter box door

To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, .In this video, I am going to explain about how to create Rolled Sheet Metal & Tubes.I am to explain in detail about below topics,1. Rolled Sheet Metal2. Shee. Learn how to create a SOLIDWORKS rolled component using sheet metal tools so you will be able to unroll/flatten the component if required.

SolidWorks does offer a feature called “Sheet Metal Lofted Bend” that allows users to roll sheet metal. This feature enables you to create rolled components by lofting between . SOLIDWORKS designers are always looking for tricks to flatten sheet metal designs within CAD. This gives a few examples of how to do that with a round desig.Properties specific to sheet metal parts are calculated and displayed in the Cut-List Properties dialog box. When you assign a custom material to a sheet metal part, you can link the sheet .

In this video, I’ll show you how to use the Insert Bends command to tackle three common use cases for designing and flattening a rolled cylinder or cone in SOLIDWORKS Sheet Metal.

Learn how annotations are assigned to views, best practices for making cuts on rolled sheet metal cylinders, and how to modify features to support the Model Items command.

If you need to add fasteners to a rolled sheet metal part in SOLIDWORKS this outlines the correct procedure. You may be familiar with the technique of creating a rolled sheet metal part and then rolling back in the .

SolidWorks provides a comprehensive set of tools for designing sheet metal components, including the ability to roll sheet metal using the “Sheet Metal Lofted Bend” feature. By leveraging this feature, engineers can create accurate representations of rolled components within their CAD models.You may be better off measuring the length of what will become the circular top and circular bottom of the cone from the flat pattern then use that to construct the cone directly as a 3D sheet metal piece to flatten (like this: GoEngineer - SOLIDWORKS: Sheet Metal Cone).Multibody sheet metal cut lists offer the same features as weldment cut lists, including the ability to automatically organize and update sheet metal bodies, and view sheet metal properties. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your .

By using the Base Flange/Tab, create a circle with a small gap in it. That gap is for the cut on the sheet to make it possible to roll in a cylinder form. After that you just add your thickness and bend radius. If you can use your flatten view then you know the sheet has a correct bend in it. Checkout our free inar for SolidWorks BeginnersDesigning a sheet metal weldment that uses parts with a 16 inch bend radius in 14-gauge 304 stainless. Will be roll-forming these parts. Created the details using lofted bend sheet metal function. Afterwards I open up the feature and I'm concerned about what Bend Parameters to use. Inside Bend Radius? (for some reason the default is .029 in.)

The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. We have some parts that are rolled from sheet metal parts into tubes and cones (i.e., no flat surfaces), does anyone know how to do this in SolidWorks? Catalog. View in SOLIDWORKS User Forum View on Forum . Use your 3DEXPERIENCE ID to log in. .You can roll back all bends from a sheet metal part in which bends have been inserted so that you can make additions, such as adding a wall. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our .However, in my application the bead roll follows a curved path so I would have to create a custom forming tool library part for each feature on each part. right? Catalog. View in SOLIDWORKS User Forum View on Forum . Use your 3DEXPERIENCE ID to log in. Preview | SOLIDWORKS USER FORUM Bead Roll. TK By Tim Koritz 03/09/09. My fabricator has a . The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. I'm trying to design a panel that is rolled sheet metal. I have my base part designed, and I want to know how I put a bend in the whole part such that it was put into a sheet metal roller (ie. it has a radius throughout the whole part). .

The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. having trouble flattening rolled sheet metal part . when I flatten it the rolled elements disappear . any ideas would be great . many thanks all . EDITED BY MODERATOR: Moved to the Sheet Metal space. Please post to the appropriate space when one exists. .

You can roll back all bends from a sheet metal part in which bends have been inserted so that you can make additions, such as adding a wall. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our .

solidworks unfold sheet metal

Exercise 23 - Cylindrical Sheet Metal parts, Linear sketch patternsWe are quite familiar with getting the flatten pattern from a designed shape. But what if we would like to do the reverse. Here we explain how you can use So. I've got a simple sheet metal part where I need to chamfer the ends for welding, and roll into a half circle (ish). I've tried going about this many ways and they've all failed. The company I work for has a work around which I hate - they set up two configurations, with the rolled chamfer suppressed in flat pattern, then add a new chamfer after .

ALL posts related to SOLIDWORKS are welcome. Share what you know. Learn what you don't. . or rollback to between the bend features and cut it flat and let it roll back up using sheet metal. . You can try and convert the part to sheet . The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. I've been trying to add reference planes to a sheet metal part by rolling back to before the first sheet metal feature (I want to place the SM sketches on new planes) but when I try to put the sketches on the new planes they are greyed out, like wise if I want to .The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. Hi All, I'm trying to develop the sheet metal flat pattern for the attached part but cannot get the tangent arc for the 22" radius to pick up the intersection of 2 lines. . ROLLED SHEET METAL - TRYING TO MAKE EXTRUDED CUT ON CURVE. DK By Dave Krum 05/10/13. Hi All,Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part .

Stretch is going to depend on a LOT of factors, even how slick the rollers are, so there are no universal truths. The best way to calibrate your setup is to carefully measure and then roll a test part (or even a production test part) and measure again. Go back to SOLIDWORKS and adjust the K-Factor until the measurements line up.

Hello All, I hoping someone can help me out. I have a rolled piece of sheet metal and i would like to add flanges to it. I could only get it to work one way, and im thinking there has to be a better way to do this. I have attached 1 of my files. We also have a rolled oval (closed) with flanges.The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. I have a sheet that is 1451.96 x 2785.57mm by 2.5mm thick. . with seperate panels with more holes in them to attach equipment to it. Solidworks just .

Is there a way to take a sheet metal flat pattern and form it into a compound curve? I am trying to generate an accurate sheet metal version of the 2 wings that are highlighted below is blue. We currently generate a visual representation of the wings using a thickened surface that is approximately inserted.Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .

So most of the holes an cuts on this tank are made after the sheetmetal is rolled and weld, and are done through a punching machines which can either cut an deform the rolled sheet metal. I imagine using a forming tool in rolle dsheetmetals is a common feature in many industries.

The thing is that I found out that SW does not allow .Hi, I am still working my way through learning sheet metal in Solidworks and could use some help rolling a flat pattern into a cylinder. I have a flat plate drawn and extruded already with a cutout pattern. I am trying to develop the rolled cylinder for a visual for the fabrication shop without having to start everything from scratch.

Using Forming Tools with Sheet Metal. Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. Sheet Metal Parts. Multibody Sheet Metal Parts. SOLIDWORKS multibody part functionality lets you work with several bodies in one part to create .

solidworks unbend sheet metal

Obtenha dicas e recomendações de especialistas para maximizar a eficiência e obter os melhores resultados com nossas diretrizes de projeto de usinagem CNC.

roll sheet metal solidworks|sheet metal modeling in solidworks