ab tech cnc machining This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and .

When it comes to sheet metal welding, the type of metal you use can make all the difference. The choice of metal for sheet metal welding depends on the project’s specific .

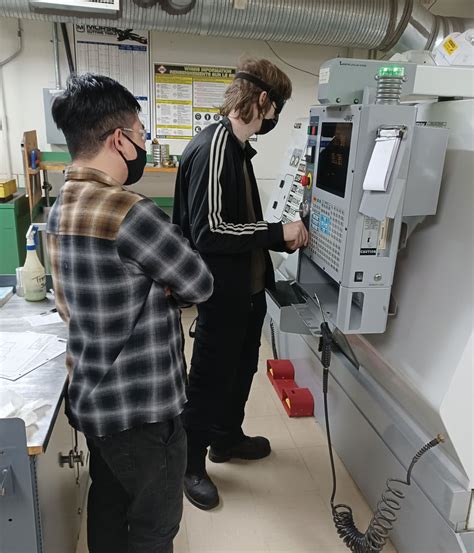

0 · nbcc cnc program

1 · nbcc cnc machine

2 · cnc machine program

Learn what size electrical box screws you need for your next project with our handy guide. We'll cover everything from standard sizes to metric measurements, so you can be sure you're getting the right screws for the job.

The Computer-Integrated Machining Technology curriculum is designed to prepare students with the analytical, creative, and innovative skills necessary to take a production idea from an initial .

This course introduces the manual programming, setup, and operation of .This course introduces the manual programming, setup, and operation of .The Advance Machining Operator Certificate program provides a .This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and .

This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and .In our CNC Machining program, you’ll learn the skills needed to bring design ideas to life. We’ll teach you how to program, set-up, troubleshoot, and operate advanced machine tools so that .

nbcc cnc program

CNC precision machining is a computer-controlled manufacturing process that focuses on the ability to consistently replicate specific attributes across a large production volume, ensuring that the dimensions and .ABTech’s high-precision air-bearing spindles provide the ultimate performance utilizing a proven and robust design. High stiffness, load capacity, and very low error motion make these spindles ideal for precision machining, grinding, . 5-axis CNC machining represents a groundbreaking leap in manufacturing technology, offering unmatched flexibility and precision. By enabling simultaneous movement .

CNC machining, is a cutting-edge technology revolutionizing the manufacturing industry. With its unmatched precision, efficiency, and versatility, CNC machining is essential for engineers and . AI and machine learning will revolutionize CNC machining in automotive production. Predictive maintenance algorithms will minimize downtime, while dynamic tool path .The Advance Machining Operator Certificate program provides a foundational knowledge in manufacturing and machining operations, print reading, CNC, industrial safety, 5S, Lean .The Computer-Integrated Machining Technology curriculum is designed to prepare students with the analytical, creative, and innovative skills necessary to take a production idea from an initial concept through design, development, and production, resulting in a finished product.

This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and inspection. Upon completion, students should be able to manufacture simple parts using CNC machining centers.

This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and inspection. Upon completion, students should be able to manufacture simple parts using CNC machining centers.In our CNC Machining program, you’ll learn the skills needed to bring design ideas to life. We’ll teach you how to program, set-up, troubleshoot, and operate advanced machine tools so that you’re ready to become a valuable member of any industrial engineering team . CNC precision machining is a computer-controlled manufacturing process that focuses on the ability to consistently replicate specific attributes across a large production volume, ensuring that the dimensions and characteristics of multiple units .ABTech’s high-precision air-bearing spindles provide the ultimate performance utilizing a proven and robust design. High stiffness, load capacity, and very low error motion make these spindles ideal for precision machining, grinding, single-point diamond turning, and high-precision scanning.

5-axis CNC machining represents a groundbreaking leap in manufacturing technology, offering unmatched flexibility and precision. By enabling simultaneous movement across five axes, these machines streamline production, reduce setup times, and create intricate designs with ease. Here's how 5-axis CNC machines are transforming manufacturing: 1.CNC machining, is a cutting-edge technology revolutionizing the manufacturing industry. With its unmatched precision, efficiency, and versatility, CNC machining is essential for engineers and product developers alike. From aerospace components to custom automotive parts, this innovative process ensures high-quality output and cost-effectiveness.

AI and machine learning will revolutionize CNC machining in automotive production. Predictive maintenance algorithms will minimize downtime, while dynamic tool path optimization and automated quality control systems will enhance efficiency and product consistency.The Advance Machining Operator Certificate program provides a foundational knowledge in manufacturing and machining operations, print reading, CNC, industrial safety, 5S, Lean manufacturing, quality control, and Total Productive Maintenance (TPM) with an emphasis on preventative maintenance.The Computer-Integrated Machining Technology curriculum is designed to prepare students with the analytical, creative, and innovative skills necessary to take a production idea from an initial concept through design, development, and production, resulting in a finished product.This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and inspection. Upon completion, students should be able to manufacture simple parts using CNC machining centers.

This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and inspection. Upon completion, students should be able to manufacture simple parts using CNC machining centers.

In our CNC Machining program, you’ll learn the skills needed to bring design ideas to life. We’ll teach you how to program, set-up, troubleshoot, and operate advanced machine tools so that you’re ready to become a valuable member of any industrial engineering team . CNC precision machining is a computer-controlled manufacturing process that focuses on the ability to consistently replicate specific attributes across a large production volume, ensuring that the dimensions and characteristics of multiple units .

ABTech’s high-precision air-bearing spindles provide the ultimate performance utilizing a proven and robust design. High stiffness, load capacity, and very low error motion make these spindles ideal for precision machining, grinding, single-point diamond turning, and high-precision scanning. 5-axis CNC machining represents a groundbreaking leap in manufacturing technology, offering unmatched flexibility and precision. By enabling simultaneous movement across five axes, these machines streamline production, reduce setup times, and create intricate designs with ease. Here's how 5-axis CNC machines are transforming manufacturing: 1.

CNC machining, is a cutting-edge technology revolutionizing the manufacturing industry. With its unmatched precision, efficiency, and versatility, CNC machining is essential for engineers and product developers alike. From aerospace components to custom automotive parts, this innovative process ensures high-quality output and cost-effectiveness.

AI and machine learning will revolutionize CNC machining in automotive production. Predictive maintenance algorithms will minimize downtime, while dynamic tool path optimization and automated quality control systems will enhance efficiency and product consistency.

nbcc cnc machine

Here are our reviews of the 5 best welders for auto body work on the market. 1. Hobart 500559 Handler 140 Wire Welder. 2. Forney Easy Weld 261, 140 FC-i Welder.Metal lunch box with colorful animated scenes from the movie Indiana Jones and the Temple of Doom depicted on all sides. A thermos is included. Filmmaker George Lucas conceived of Indiana Jones as a globe-trekking archeologist to pay homage to classic Hollywood adventure films.

ab tech cnc machining|cnc machine program