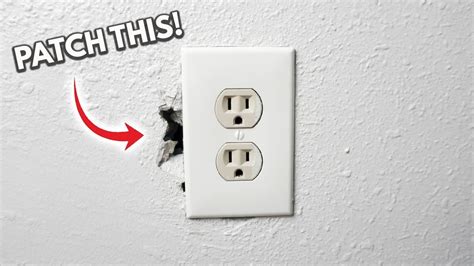

how to fix drywall cut too big for junction box An oversized drywall cutout around an electrical box can ruin the appearance of an otherwise perfect taping job. The best way to fix it is with . Using a junction box makes installing new 7-way wiring much easier. Often times, people will run the wires from a 7-way such as yours to a junction box like part #38656. From there, they will run the standard wire colors to the trailer lights, brakes.

0 · overcut drywall repair

1 · fix drywall around electrical box

2 · electrical box hole too big

3 · electrical box cutout fix

4 · drywall repair near electrical box

5 · drywall box outlet repair

6 · drywall around electrical box outlet

7 · drywall around electrical box

Computer numeric control, or CNC, is a technology around computer programs and software. CNC is the foundation of automated machining today through preprogrammed computer language. Embedding these programs into machines makes manufacturing precise, high-speed, and efficient. They are based on standardized languages in G-codes and M-codes.CNC movements are based on the X, Y and Z axes. The tool is positioned using stepper or servo motors, which act on the movements based on the code obtained from the original 3D model of the part you want to create – called the G-code. Numerical controls describe how fast to move the spindle (the . See more

overcut drywall repair

An oversized drywall cutout around an electrical box can ruin the appearance of an otherwise perfect taping job. The best way to fix it is with . Learn how to quickly and effectively fix horribly cut or damaged drywall around electrical boxes. https://www.youtube.com/watch?time_continue=7&v=eLAGQpLg9cI. How To Repair Overcut Or Damaged Drywall Around Electrical Box Outlet | DIY Tutorial For Beginners! ITEMS I USED: - Sheetrock Drywall Repair Clips - https://amzn.to/3xGxMA0- Wood. Fill the gap using a special trick. so we've got an electrical box where th where there's nothing for it at the bottom to grip so I made this two layer piece of wood thing that where this and.

How to Repair an Outlet Hole Cut Too Large Having an oversized drywall cutout around an electrical box can ruin the appearance of a perfectly executed taping job. You can fix it with joint tape and drywall compound. Sheetrocker cut the hole too big on an old work box opening, and the tabs aren't catching. Any neat tricks or "gadgets" to fix this issue - short of cutting out the rock and patching in a new piece with a proper sized cut out? We cut the holes in the drywall for the electrical outlet boxes too big and now the wings on the old-construction boxes can't clamp the wall. What are my options? We just .

You must determine how to repair overcut or damaged drywall around the electrical box outlet. The 5-step guide indicates removing the electrical covers to measure the . We cut the holes in the drywall for the electrical outlet boxes too big and now the wings on the old-construction boxes can't clamp the wall. What are my options? We just finished painting yesterday after weeks of hanging, taping and sanding the drywall.While replacing my bathroom vanity lights I found that the old junction box doesn't sit flush with the wall and with my new vanity it is an issue. I tried getting a 'old work' junction box that latches on to the drywall but the hole is a little too big . Sheetrocker cut the hole too big on an old work box opening, and the tabs aren't catching. . We usually have the problem being the drywall guys didnt cut out for the box.Why was this guy doing your job to start with ?Many .

Hanging drywall in a kitchen and made the cutouts too big around the outlet boxes. Not really interested in hearing how to cut these more accurately, but am interested in hearing the good fix. (When the hole is too big, then the outlet ears don't have anything to grab onto. Pushing in plugs breaks the mud around the box.)Patch the old hole with a self-sticking drywall patch, then mount a new box to the joist about 8" further away from the wall. There are boxes that can be screwed right into the joist from below the ceiling (look for Madison Electric Products Fan and Fixture 1-Gang Gray Polycarbonate New Work/Old Work Standard Ceiling Fan Ceiling Electrical Box).Transfer the measurements to the drywall and draw a box. Drive a nail through the center point for a pilot hole. Set the circle cutter to cut about 1/8 in. larger than the fixture, stick the .

Follow the marked lines to cut the area using a drywall cutting saw. After a few seconds of cutting, the damaged drywall would come off. You can inspect the depth of the damage by looking at the back. The back side of the piece of the wall would showcase the depth of the damage. Step 3: Place The Drywall Repair Clip If the tabs are not securely engaging the back surface of the drywall, there is another type of sheet metal clamp which is inserted between the box and the drywall and which has ears which clamp to the back surface of the drywall and other tabs which fold into the box. This keeps the box from pulling out when a plug is pulled out.

You can cut the drywall back a few inches, then seam a piece of filler drywall by using a lath on the back. You screw the lath to the drywall on both sides of the seam, then tape and mud it. Long as the box is securely mounted, it shouldn't be a problem. But there's a cheap and dirty way you can fix this if you want to deal with it later.

I'd take it a step further and actually expand the drywall hole expose the adjacent section of the stud. Then attach wood support shims across the back of the hole, and cut a new drywall patch big enough to overlap the stud and screw it down. Only thing worse than fixing drywall is is fixing drywall again. –

I need to mount a 2 gang dry lining backbox on a drywall. Now, the hole in the wall is too long, so the clips won't grip (or rather, only one clip will grip where the other one would be too far from the drywall edge). For reasons beyond my control I .

Let me show you how to fix a bad electrical box cutout. You got this! If the drywall hole is so beat up that it's enlarged too much for the wings on the box, you may need to do a little drywall repair. Possibly you could slip a thin piece of wood behind the beat up part of the hole and glue it to the back of the drywall there. If the wood is thin enough the wings should still be able to reach back far enough to grip. I read it as the box just got pushed into the wall and dropped down. He's trying not to cut the wall to get it. I could be wrong though. I just had another thought (very dangerous:laughing but if the box did just fall into the wall, just leave it and get another box.:thumbsup: Peter might even send you a nice blue one!:thumbup:If the box is not immediately up to the stud, rather it's somewhere in between the studs, I would follow the advice of the comment of about putting some wood in. Need two pieces of 3/4-in thick stock, and drywall screws, place them above .

If me, I'd clean it all out as much as possible and fill the screw holes and surrounding areas with 2-part epoxy. Then drill new holes. You can buy switch & outlet spacers at the big box in the electrical section (there's even a picture of .

fix drywall around electrical box

If the box is as bad as you say and the other suggested methods don’t work, you can use a multi tool or sawzall (very, very carefully and slowly) to cut the nails holding the box to the stud. Pull the box out of the wall and look inside to see . 13 Tips on How to Fix an Outlet Hole Cut Too Big 1 . Use a Drywall Patch. One of the easiest ways to fix an outlet hole that is cut too big is by using a drywall patch. These patches are readily available at most hardware stores and can be easily installed without any special tools.

Depending on the force of the "ripped out of the wall". You might want to open the drywall back to the first studs , and follow the cable to the first staple or penetration, to see that the jacket of the romex wasn't peeled like a banana. then add a backing block and reclose the wall. For the easiest wall fixes use these types of composite drywall repair products for cracks, holes and drywall mistakes. Let me know if you have any questions in the comments section or what kind of drywall repair project you’re working on? Thanks so much for watching! Take care, -Paul ~~~~~ Watch the entire >How to repair holes around .I like to use metal boxes with the expanding wings for cut-in work, but the existing opening happens to be too tall for the vertical tabs on the box to grab. I'd rather not do any drywall work on this one, as matching that textured surface is a huge pain. I'm looking for some sort of snazzy (and code-legal) trick to support this box. So after all the drywall is installed and finished my finish electricians come in and often times complain about the drywall work around the electrical boxes. For example holes cut too big that the tabs have nothing to sit on or too much mud in .

ITEMS I USED ON THIS VIDEO:- WAGO Wire Connectors (36 Pieces) - https://amzn.to/3l38lmA- WAGO Wire Connectors (75 Pieces) - https://amzn.to/3PhsmDS- WAGO Wir.Just settling. Happens with new construction. Easiest fix that doesn't involve cutting out any drywall will be just a deep switch plate. They sit flush with the drywall instead of the junction box. You might need to loosen the screws holding the switches themselves in and bend back the tabs so they sit right, but it's no biggie. You linked to a new-work box, designed to be nailed into a stud before drywall goes on. Old-work boxes have clamps that attach them to drywall already in place. Boxes help prevent fires by containing arcing from bad connections away from combustible wood.

That’s a retrofit junction box and some hack cut the hole way too big. There are little flaps that swing out when you tighten the screws to compress it against the wall. Go to the Depot or Lowes grab a fresh one and try the instal again. Place behind the drywall above and below the hole spaced for the box you are using. Secure with 2 drywall screws in each piece. Install the box with screws thru the box ears and enough plastic box spacers to hold the front of the box flush with the front of the wall. Caulk the gap around the box and use Spackle or drywall mud to cover the screws.

8ft sheet metal

Before CNC existed, there was only NC. This means Numerical Control (without the “C” of Computer), where back in the 1950s punched tape was used to manually input commands on to data cards to describe where to move the machine and tools to cut parts. This was . See more

how to fix drywall cut too big for junction box|drywall around electrical box