butt welding sheet metal stud welder Butt welds can be used when welding both thin sheet metal and thick metal, but there are specific steps in weld preparation. The thickness of the metal pieces will indicate whether the butt joints are square or beveled. Transit PTMW supplies Traction Power Substations, Train Control Rooms, and various other enclosures for major U.S. metropolitan cities such as New York City, Los Angeles, Chicago, Washington D.C., and Boston.

0 · how to butt weld sheet metal

1 · butt welding structure

2 · butt welding steel

3 · butt welding design

4 · butt weld material

5 · butt weld example

6 · butt joint preparation

7 · butt joint in welding

TRAVELISIMO Electric Lunch Box for Adults 80W, Fast Portable Heated Lunch Box Food Warmer 12/24/110V, Leakproof, SS Container, Heating for Car Truck please s.Experience TRAVELISIMO’s top-rated electric lunch boxes, designed for on-the-go convenience. Enjoy perfectly heated meals anytime, anywhere with our ultra-reliable, self-heated lunch .

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt. Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across .

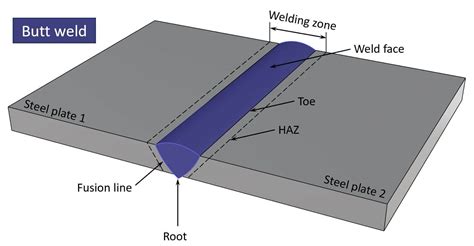

A butt weld is a welding technique where two metal pieces are joined together along their edges in a single plane. This creates a strong and seamless bond, commonly used in the construction, manufacturing, and . Butt welds are a popular welding technique used in metal fabrication. They join two pieces of metal by heating and pressing the edges together, creating a strong bond. Different types of butt welds include gas .Butt welds can be used when welding both thin sheet metal and thick metal, but there are specific steps in weld preparation. The thickness of the metal pieces will indicate whether the butt joints are square or beveled.

Butt welding sheet metal is a very important skill to develop for replacing sheet metal in your restoration. Joint preparation and welder setup are the keys to a successful job. In the above .Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across various industries.

The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG) A butt weld is a welding technique where two metal pieces are joined together along their edges in a single plane. This creates a strong and seamless bond, commonly used in the construction, manufacturing, and automotive industries for its reliability and structural strength. Butt welds are a popular welding technique used in metal fabrication. They join two pieces of metal by heating and pressing the edges together, creating a strong bond. Different types of butt welds include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW).

Butt welds can be used when welding both thin sheet metal and thick metal, but there are specific steps in weld preparation. The thickness of the metal pieces will indicate whether the butt joints are square or beveled.

Butt welding sheet metal is a very important skill to develop for replacing sheet metal in your restoration. Joint preparation and welder setup are the keys to a successful job. In the above video tips are given for the actual welding process as well as some setup information.Butt welding is a fusion welding technique used to join two pieces of metal along a single plane. It involves bringing the edges of the two workpieces together and then melting and fusing them to create a strong and continuous joint. Discover the art of butt welding with our detailed guide. Learn various methods, techniques, and tips to perfect your welding skills. Ideal for beginners and pros alike. A butt weld consists of two pieces of metal placed next to each other “end-to-end” in the same plane. Applying a continuous weld down the centerline welds the pieces together. There is no stock overlap, and the joint can have a root opening.

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across various industries. The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG) A butt weld is a welding technique where two metal pieces are joined together along their edges in a single plane. This creates a strong and seamless bond, commonly used in the construction, manufacturing, and automotive industries for its reliability and structural strength.

Butt welds are a popular welding technique used in metal fabrication. They join two pieces of metal by heating and pressing the edges together, creating a strong bond. Different types of butt welds include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW).

Butt welds can be used when welding both thin sheet metal and thick metal, but there are specific steps in weld preparation. The thickness of the metal pieces will indicate whether the butt joints are square or beveled.

Butt welding sheet metal is a very important skill to develop for replacing sheet metal in your restoration. Joint preparation and welder setup are the keys to a successful job. In the above video tips are given for the actual welding process as well as some setup information.Butt welding is a fusion welding technique used to join two pieces of metal along a single plane. It involves bringing the edges of the two workpieces together and then melting and fusing them to create a strong and continuous joint. Discover the art of butt welding with our detailed guide. Learn various methods, techniques, and tips to perfect your welding skills. Ideal for beginners and pros alike.

how to butt weld sheet metal

septic tank drain field distribution box

septic distribution box for sale near me

Tri-State has installed everything from exhaust hoods and small ventilation fans to 250-ton chillers and 1.5 million BTU boilers; from small heat pumps to huge rooftop heating and cooling units; plus air handling systems, pumps of all .

butt welding sheet metal stud welder|butt joint preparation