5s for cnc machine shop Use your free implementing 5S checklist to implement 5S in your machine shop or facility and further your lean manufacturing efforts. Numco USA is your number one sourcing agent for custom metal stampings. We work with only the best, most capable domestic and offshore contractors to ensure that your parts and components match your designs exactly and provide the fit, form, and function you require.

0 · making 5s a machine shop

1 · how to make 5s work

2 · how to implement 5s

3 · 5s in manufacturing workplace

4 · 5s in manufacturing process

5 · 5s in manufacturing industry

6 · 5s in machine shop

Dive into our online wholesale sheet metal parts products catalog on globalsources.com! Source over 1635 sheet metal parts for sale from manufacturers with factory direct prices, high quality & fast shipping.

Learn why your shop should embrace 5S in the workplace, and how to do it. A 5S methodology can help even a small machine shop identify and achieve process efficiencies, which in turn . In the competitive field of metal CNC (Computer Numerical Control) machining, maintaining an efficient and organized workshop is essential. The 5S methodology—Sort, Set . This is a 5s training video for our cnc machine shop.Use your free implementing 5S checklist to implement 5S in your machine shop or facility and further your lean manufacturing efforts.

Find out why 5S is the cornerstone of lean manufacturing. Implement 5S to arrange your workspace to eliminate waste. Discover how to utilize this lean manufacturing methodology in . When it comes to 5S, checklists, scorecards, charts and “before and after” photographs can be posted in visible areas to show compliance and summarize progress .

Use our 5S checklist to help implement 5S in your facility & increase your organization and efficiency. Learn steps to take that make implementing 5S easy. 7 Ways a CNC Shop May Implement Lean Principles 1. Maximizing Tooling Efficiency (tooling selection) Tooling efficiency is a critical factor for a machine shop because this single factor can make or break the .

Yes, 5S can free up floor space, can eliminate wasteful motion, can reduce safety hazards, can minimize lost tools and can highlight excess inventory. But, the main reason for using the 5S tool is to create a sustainable .Learn why your shop should embrace 5S in the workplace, and how to do it. A 5S methodology can help even a small machine shop identify and achieve process efficiencies, which in turn can lead to a rosier bottom line. The 5S is a methodology aimed at optimizing the productivity and reducing waste at the factory. It makes use of visual cues and an orderly workplace to achieve consistent results. The 5S is implemented by small teams working together to achieve a higher goal of efficiency.

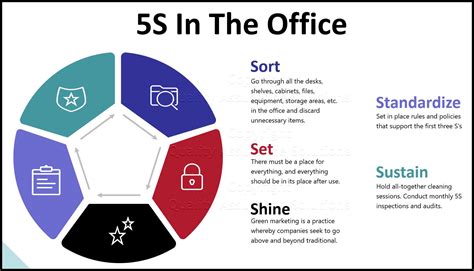

In the competitive field of metal CNC (Computer Numerical Control) machining, maintaining an efficient and organized workshop is essential. The 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—offers a structured approach to achieving cleanliness, safety, and efficiency.This is a 5s training video for our cnc machine shop.Use your free implementing 5S checklist to implement 5S in your machine shop or facility and further your lean manufacturing efforts.

Find out why 5S is the cornerstone of lean manufacturing. Implement 5S to arrange your workspace to eliminate waste. Discover how to utilize this lean manufacturing methodology in your shop today. Tips to introduce this useful practice into your shop. When it comes to 5S, checklists, scorecards, charts and “before and after” photographs can be posted in visible areas to show compliance and summarize progress made throughout the program. Communicating instances of program compliance, as well as plans for addressing non-compliance, will motivate employees to stick with the program. 4.

Use our 5S checklist to help implement 5S in your facility & increase your organization and efficiency. Learn steps to take that make implementing 5S easy.

7 Ways a CNC Shop May Implement Lean Principles 1. Maximizing Tooling Efficiency (tooling selection) Tooling efficiency is a critical factor for a machine shop because this single factor can make or break the quality of parts produced by any CNC machine. Yes, 5S can free up floor space, can eliminate wasteful motion, can reduce safety hazards, can minimize lost tools and can highlight excess inventory. But, the main reason for using the 5S tool is to create a sustainable visual workplace where problems are quickly identified.Learn why your shop should embrace 5S in the workplace, and how to do it. A 5S methodology can help even a small machine shop identify and achieve process efficiencies, which in turn can lead to a rosier bottom line.

making 5s a machine shop

The 5S is a methodology aimed at optimizing the productivity and reducing waste at the factory. It makes use of visual cues and an orderly workplace to achieve consistent results. The 5S is implemented by small teams working together to achieve a higher goal of efficiency.

In the competitive field of metal CNC (Computer Numerical Control) machining, maintaining an efficient and organized workshop is essential. The 5S methodology—Sort, Set in Order, Shine, Standardize, and Sustain—offers a structured approach to achieving cleanliness, safety, and efficiency.This is a 5s training video for our cnc machine shop.Use your free implementing 5S checklist to implement 5S in your machine shop or facility and further your lean manufacturing efforts.

Find out why 5S is the cornerstone of lean manufacturing. Implement 5S to arrange your workspace to eliminate waste. Discover how to utilize this lean manufacturing methodology in your shop today. Tips to introduce this useful practice into your shop.

When it comes to 5S, checklists, scorecards, charts and “before and after” photographs can be posted in visible areas to show compliance and summarize progress made throughout the program. Communicating instances of program compliance, as well as plans for addressing non-compliance, will motivate employees to stick with the program. 4. Use our 5S checklist to help implement 5S in your facility & increase your organization and efficiency. Learn steps to take that make implementing 5S easy. 7 Ways a CNC Shop May Implement Lean Principles 1. Maximizing Tooling Efficiency (tooling selection) Tooling efficiency is a critical factor for a machine shop because this single factor can make or break the quality of parts produced by any CNC machine.

how to make 5s work

Wholesale will be open: Friday, Aug. 30th, 7 am to 3 pm; Wholesale will be CLOSED Monday Sept. 2nd: Wholesale will return to regular hours Tues. Sept. 3rd – open at 7 am. Have a great holiday weekend! Continue reading.

5s for cnc machine shop|5s in manufacturing process