application of cnc machines With CNC technology, machining can be used to effectively cut materials across a wide range of industries and applications for both at-home hobbyists and large-scale production shops. Here are some of the most effective uses for CNC machines and how you can use a CNC router or CNC plasma to improve your work from initial programming to final cut. 6 Methods of Sheet Metal Welding. Now, let’s take a comprehensive look at some methods for melding metal sheets. 1. MIG Welding. Metal Inert Gas welding (MIG), also known as Gas Metal Arc Welding. It involves feeding a continuous solid wire electrode into the weld puddle with a welding gun.

0 · schematic diagram of cnc machine

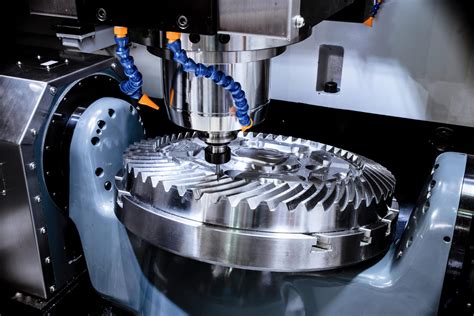

1 · products made by milling machine

2 · industries that use cnc machines

3 · different type of cnc machines

4 · computer numerical control cnc machines

5 · companies that use cnc machines

6 · cnc machine work needed

7 · application of cnc lathe machine

GFCI protection is required for outdoor outlets rated 50 amp or less in garages and for outlets rated not over 150 volt to ground, 50 amp or less in accessory buildings and boathouses. GFCI protection is required for all receptacles rated 60 amp or less within 20 feet of a swimming pool wall.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

v&r sheet metal

With CNC technology, machining can be used to effectively cut materials across a wide range of industries and applications for both at-home . Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining. CNC machining is the go-to method for making jewellery and etching and engraving. Jewelry-making uses CNC milling machines, CNC lathes, CNC routers, and CNC laser engraving machines. A jewellery CNC machine not only helps manufacture and form metal jewelry but also in grinding and polishing items.

schematic diagram of cnc machine

With CNC technology, machining can be used to effectively cut materials across a wide range of industries and applications for both at-home hobbyists and large-scale production shops. Here are some of the most effective uses for CNC machines and how you can use a CNC router or CNC plasma to improve your work from initial programming to final cut. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to .

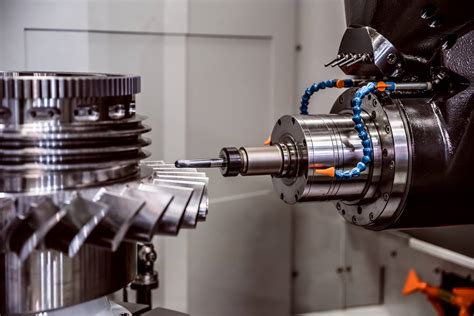

To execute CNC machining, an operator prepares instructions, guiding the machine’s tool movements, speed, and depth of material removal. Originally hand-written, these instructions are now generated by advanced software systems. Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them.CNC machines are widely used in mold manufacturing, allowing for the efficient machining of complex mold shapes. It is essential for injection molding, casting, and other manufacturing processes. The precision of CNC technology shortens . CNC Machining is short for Computer Numerical Control Machining, and these machines can achieve an accuracy and consistency that would be hard to match with a manual process. Using pre-programmed computer software, CNC machines can produce items more quickly and with better surface finishes.

products made by milling machine

industries that use cnc machines

Computer Numerical Control (CNC) machines have revolutionized manufacturing, offering unmatched precision, efficiency, and versatility. In this article, we will delve into what CNC machines.

CNC machines use digital instructions (such as G-Code or M-Codes) to move and tool and workpiece in a CNC machine. For machining, the Operator firstly loads digital instructions (CNC Program) and fixes the workpiece in the machine. Afterward, machines perform required machining operations automatically with minimal operator interference.

Since CNC machines can process almost any type of material, their applications are near limitless. From direct part production to rapid prototyping, this article looks at the various robust applications of CNC machining.

CNC machining is the go-to method for making jewellery and etching and engraving. Jewelry-making uses CNC milling machines, CNC lathes, CNC routers, and CNC laser engraving machines. A jewellery CNC machine not only helps manufacture and form metal jewelry but also in grinding and polishing items. With CNC technology, machining can be used to effectively cut materials across a wide range of industries and applications for both at-home hobbyists and large-scale production shops. Here are some of the most effective uses for CNC machines and how you can use a CNC router or CNC plasma to improve your work from initial programming to final cut. CNC (Computer Numerical Control) machining is the process of using a machine to automatically remove material from raw stock based on a set of computer-generated instructions. It can be performed on almost any material from expanded polyurethane foam to . To execute CNC machining, an operator prepares instructions, guiding the machine’s tool movements, speed, and depth of material removal. Originally hand-written, these instructions are now generated by advanced software systems.

Have you ever wondered how CNC machines shape our world? These versatile tools revolutionize manufacturing, handling tasks from simple drilling to complex milling. In this article, we’ll explore the various types of CNC machines, their unique applications, and the technology that drives them.CNC machines are widely used in mold manufacturing, allowing for the efficient machining of complex mold shapes. It is essential for injection molding, casting, and other manufacturing processes. The precision of CNC technology shortens .

CNC Machining is short for Computer Numerical Control Machining, and these machines can achieve an accuracy and consistency that would be hard to match with a manual process. Using pre-programmed computer software, CNC machines can produce items more quickly and with better surface finishes. Computer Numerical Control (CNC) machines have revolutionized manufacturing, offering unmatched precision, efficiency, and versatility. In this article, we will delve into what CNC machines.

different type of cnc machines

computer numerical control cnc machines

Sheet metal can be quite thin and delicate, which means that the fasteners need to be chosen wisely. This article aims to explore the two types of fasteners that are commonly used with sheet metal, along with their benefits and limitations.

application of cnc machines|different type of cnc machines