cnc machines wiki CNC basics. To better understand the problems involved to successfully use your Rhino data for a CNC-controlled machining or cutting type operation, you need to understand the CNC process . A full service, custom metal fabrication & welding services company serving Maryland, Virginia and the greater Washington D.C. and Baltimore Metropolitan areas since 1993. other business using similar names in the US or abroad.

0 · who invented the cnc machine

1 · when were cnc machines invented

2 · computer numerically controlled machines

3 · cnc machines wikipedia

4 · cnc machine meaning in english

5 · cnc machine history

6 · cnc machine basic knowledge

7 · cnc machine acronym

In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal welding results.

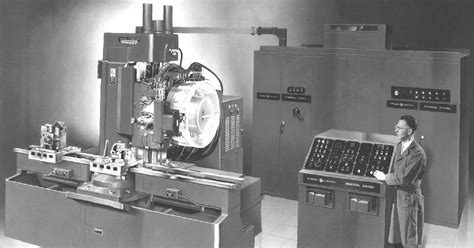

A computer numerical control (CNC) router is a computer-controlled cutting machine which typically mounts a hand-held router as a spindle which is used for cutting various materials, such as wood, composites, metals, plastics, glass, and foams. CNC routers can perform the tasks of many carpentry shop machines such as the panel saw, the spindle moulder, and the boring machine. They can .The history of numerical control (NC) began when the automation of machine tools first incorporated concepts of abstractly programmable logic, and it continues today with the .

Learn about the precision, automation, and versatility that make CNC machines essential for high-quality production. From the basics of how they operate to their advantages over traditional tools, discover why CNC .CNC machining is a subtractive manufacturing process that employs computerized controls and machine tools to remove layers of material from a stock piece, producing a custom-designed part. Common operations in CNC .CNC basics. To better understand the problems involved to successfully use your Rhino data for a CNC-controlled machining or cutting type operation, you need to understand the CNC process .

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how . What is CNC (Computer Numerical Control) Machining? The term machining generally refers to the use of a cutting tool used as part of a controlled material removal process to render a workpiece to a desired final size and .

2021-10-24 Cnc Machining Guide Comments Off on The working principle of the static pressure screw in the CNC machine tool feed system. 1. Working principle The ball screw nut pair is a transmission pair that puts balls between the screw and the nut, and the screw and the nut become a driving pair of rolling friction. Both the screw 1.

The development policy of my country’s CNC machine tools before the “Ninth Five-Year Plan” and 2010 is to focus on six types of mainframes: CNC lathes, machining centers, CNC grinders, CNC forging machine tools, CNC heavy .The worktable of the machine can move up and down, and the size has expanded the opening and closing height of the machine, making it more convenient to use. Double column hydraulic press This series of products are suitable for pressing, bending and shaping, embossing and creasing, flanging, punching and shallow drawing of small parts of .

who invented the cnc machine

sheet metal pittsburgh

Cnc Machine Wiki,Thanks!^^ tweet; Related Posts. Metal Etching Processing Technology . 2024-06-14 Sheet Metal Guide Comments Off on Metal Etching Processing Technology. Did you know? Metal etching can not only make the surface rough, with clear patterns and exquisite details, but also greatly reduce the generation of wastewater, waste gas .1. Long hole boring represented by the coaxial hole system of box parts is one of the most important contents in metal cutting. Although there are still examples of long hole boring with boring dies, guide sleeves, long boring bars supported by a bench-type milling and boring machine, or manual alignment of the workpiece by 180° rotation, in recent years, on the one .

In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer.It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers.CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) into a specified shape by following coded programmed .Nowadays, CNC spinning machines basically adopt man-machine interface operation mode, which is simple and easy to use. Reasonable operation mode can not only ensure the durability and stability of the equipment, but also improve production efficiency and .The Development Status Of 5 Axis Cnc Machine. Foreign five-axis linkage CNC machine tools appeared to adapt to the processing of polyhedrons and curved parts. With the new development of machine tool complex technology, on the basis of CNC lathes, turning and milling centers that can be milled are quickly produced.

As you choose a CNC machine, it is important to consider the types materials you want to work with, as well as the types of design files you are looking to create. CNC Mills like the Carvera and Carvera Air can work with a range of 2D and 3D design files, as well as many different materials to make limitless things with precision and .The CNC Machines (Computerized Numerical Control) are located in the Build Lab of Goldsmith and are managed and supported by the Technology Lab. Technology Lab equipment is only available to current students, faculty, and staff in the School of Architecture community. Use of the CNC Machines requires certification and a current Digital .

sheet metal pinspotter

CNC machine tools are mainly used to process parts with complex shapes, but the structure of the fixtures used is often not complicated. The selection of fixtures for CNC milling machines can first be determined according to the batch size of the production parts. For single-piece, small-batch, and large-volume mold processing, positioning and .The Advantage Of Turn-Mill Machine. Compared with conventional Cnc Machining technology, the outstanding advantages of compound machining are mainly manifested in the following aspects.. Shorten the product manufacturing process chain and improve production efficiency.A 3-axis clone of a Bridgeport-style vertical milling machine. Milling is the process of machining using rotary cutters to remove material [1] by advancing a cutter into a workpiece.This may be done by varying directions [2] on one or several axes, cutter head speed, and pressure. [3] Milling covers a wide variety of different operations and machines, on scales from small individual . In the late 1940s, a helicopter company in the United States put forward the initial idea of a CNC machine tool. In 1952, the Massachusetts Institute of Technology developed a three-axis CNC milling machine. This kind of CNC milling machine has been used for processing aircraft parts in the mid-1950s. In the 1960s, numerical control systems and .

CNC machine tools are mechatronics products that integrate multiple technologies such as machinery, electricity, hydraulics, pneumatics, microelectronics, and information. It is a working mother machine with the advantages of high precision, high efficiency, high automation and high flexibility in mechanical manufacturing equipment. . For the main daily maintenance and maintenance of cnc machine tools, first select the appropriate use environment: the use environment of CNC lathes (such as temperature, humidity, vibration, power supply voltage, frequency and interference, etc.) will affect the normal operation of the machine tool, so When installing the machine tool, it .

The failure mode, impact and criticality analysis (FMECA) is aimed at all possible failures of the product, and based on the analysis of the failure mode, determines the impact of each failure mode on the product’s work, finds out the single point of failure, and presses the severity of the failure mode The degree and its probability of occurrence determine its hazard.Swiss Machine-the full name is the spindle-type CNC lathe, it can also be called the headstock mobile CNC automatic lathe, the economical turning-milling compound machine tool or the slitting lathe. It is a precision processing equipment that can complete lathe, milling, drilling, boring, tapping, engraving and other compound processing at one .The crank is the key part of the feeder’s transmission and feeding, and its strength and toughness are required to be high. In the previous production, the crank blank of the feeder was generally made of casting materials, which had the advantages of certain strength, good plasticity and toughness; however, due to the high price of castings and rough appearance, especially the .

The high-power engraving machine can be used as a small-power engraving cnc machine. It is most suitable for large-scale cutting, embossing and carving. In the numerical control machine tool, the electric spindle usually adopts the frequency conversion speed regulation method. There are mainly three control modes: ordinary variable frequency .Desktop CNC machine with 1/4" steel plates, oversized custom extrusion (possibly the biggest on the market for a machine this size), oversized V wheels, linear rails for Z axis. Rack and pinion drive and fastest accelerations and cutting speeds. Cutting area from 19" x 19" or 35" x 35". 3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die .

A CNC machine is a type of automated tool that utilizes computer software to control the movements and operations of machinery. Unlike manual machines that require human operators to perform tasks, CNC machines operate based on pre-programmed commands, which allows for consistent and repetitive production of complex parts.

The mask machine is a multi-layer non-woven fabric through hot pressing, folding molding, ultrasonic welding, waste removal, ear strap nose bridge welding and other processes to produce various masks with certain filtering performance. . Cnc Machine Wiki,Thanks!^^ Cnc Machine; EDM; Cnc Punching Machine; Cnc Milling Machine; Cnc Lathe .

CNC machines: CNC machines are computer-controlled machines that can perform various tasks, such as cutting, drilling, engraving, and 3D printing.They use different tools and methods depending on the material and the desired shape. CNC milling machines: CNC milling machines are used to make metal parts with high precision and accuracy.They have a .

When machining parts on a cnc machine tool, before programming, the first thing you encounter is the problem of process programming. The part processing process on ordinary machine tools is actually just a process card. The cutting amount, the route, the work step arrangement in the process, etc. are often determined by the operators themselves, while the .

when were cnc machines invented

sheet metal pay

Sandblasting & Coatings and quality fabrication, welding, and production of .

cnc machines wiki|who invented the cnc machine