12-axis cnc machining Capabilities of 12-axis CNC Machining. 12-axis machines improve on 9 axis devices by offering yet more increase in cutter access and the ability to follow yet more complex curvature without additional setups. 12-axis machines have .

With wood modular construction, I like to say the best strategy is to design for the minimum number of maximum sized boxes, which also get the most bang for the buck on the shipping expenses. Steel modular is a bit different but the same simplicity rules govern.

0 · multi axis cnc machines

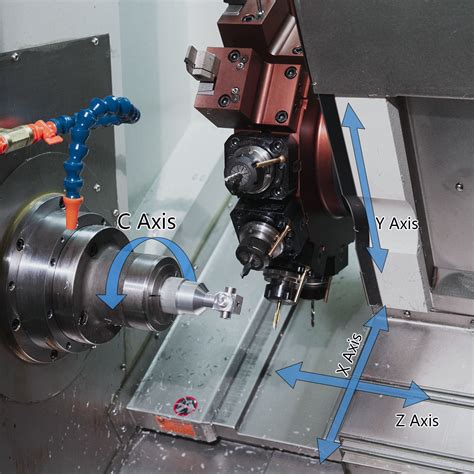

1 · mill xyz axis

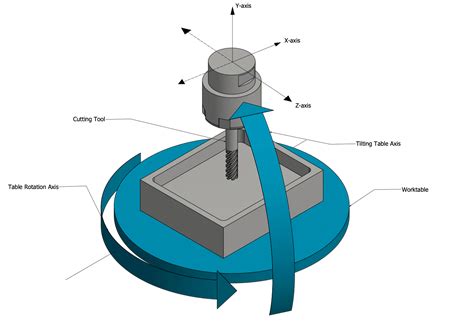

2 · cnc axis explained

3 · axis identification in cnc machine

4 · 12 axis cnc mill

5 · 12 axis cnc machine price

After completing Super Mario Odyssey and revisiting one of its kingdoms, you’ll learn that these metal blocks are actually Moon Rocks. When you revisit them in each kingdom after completing the.

3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes. The X-axis (vertical axis) is left to right along the lathe table, the Y-axis (horizontal axis) is from front to back of the table, and the . See moreA 4-axis CNC machine functions much like its 3-axis counterpart. The workpiece is in a stationary position, and the cutting tool works on it to remove material and mold the desired part. However, as the name indicates, 4-axis machining adds an axis of rotation to the . See more7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed by the axes defined by the spinning of the tool, rotation of the part, rotation of the tool head, and movement . See more

The 5-axis CNC milling machinemarks the pinnacle of innovation in 21st-century machining. It’s a precise, fast-working, precision machining powerhouse. In this setup, the X, Y, and Z-axes are similar to a 3-axis machine layout. The table then rotates along the A . See more

The 9-axis CNC combines a 4-axis lathe and 5-axis milling machine. This traditionally involves a 5-axis CNC milling machine to complete surface machining, and a 4-axis lathe to complete internal machining. This gives 9-axis machines all the rotations and . See moreCapabilities of 12-axis CNC Machining. 12-axis machines improve on 9 axis devices by offering yet more increase in cutter access and the ability to follow yet more complex curvature without additional setups. 12-axis machines have .12-Axis CNC Machining. If 9-axis CNC machining is the whole package, then its 12-axis counterpart is an absolute beast! The 12-axis CNC machines typically contain two heads that allow movement along the X, Y, Z, A, B, and C-axes. This configuration doubles productivity and accuracy while cutting down manufacturing time by half!

Capabilities of 12-axis CNC Machining. 12-axis machines improve on 9 axis devices by offering yet more increase in cutter access and the ability to follow yet more complex curvature without additional setups. 12-axis machines have advanced the technology to the point where there are no more degrees of freedom proposed or discussed.12-Axis CNC Machining. 12-axis CNC machines are advanced pieces of equipment that stands at the pinnacle of performance and capability in CNC technology. 12-axis machines typically contain two heads, each capable of moving along six different axes: X, Y, Z, A, B, and C. 12-Axis CNC Machining. If 9-axis CNC machining is the whole package, then its 12-axis counterpart is an absolute beast! The 12-axis CNC machines typically contain two heads that allow movement along the X, Y, Z, A, B, and C-axes. This configuration doubles productivity and accuracy while cutting down manufacturing time by half! 12-axis CNC. The 12-axis CNC machine is at the top of the performance and capability list for CNC machine. The design of the machine features 2 heads that facilitate movement along axes X, Y, Z, A, B and C planes. 12-axis CNC machines are designed for the most demanding operations that have an array of complexities in their design.

Verify the power requirement before running power for your machine. This rotary fits this particular machine, but may require alternative fixturing for proper positioning, such as a sub-plate or alternate T-slot. Need help finding the right machine? Let us help you find the right one for your shop. Need More Information?

multi axis cnc machines

To grasp the significance of a 12-axis CNC machine, it is essential to understand the fundamentals of CNC machining. We will explore how a CNC machine works, breaking down its components and functions, before diving into the specifics of the 12-axis variant.From 3-axis to 12-axis CNC milling: Learn how different axes impact production capabilities and choose the right machine for your project.

freightliner electric box truck

12-Axis CNC Machining. If 9-axis CNC machining is the whole package, then its 12-axis counterpart is an absolute beast!The LICO LNTS Series multi-slide CNC screw machines are ruggedly built and capable of form tool use with each slide having a full 2-axis servo-controlled travel. The LNTS, with 3 or 4 multi-axis slides and an 8-position turret, can overlap up to 5 tools at once.12-Axis CNC Machining. If 9-axis CNC machining is the whole package, then its 12-axis counterpart is an absolute beast! The 12-axis CNC machines typically contain two heads that allow movement along the X, Y, Z, A, B, and C-axes. This configuration doubles productivity and accuracy while cutting down manufacturing time by half!

Capabilities of 12-axis CNC Machining. 12-axis machines improve on 9 axis devices by offering yet more increase in cutter access and the ability to follow yet more complex curvature without additional setups. 12-axis machines have advanced the technology to the point where there are no more degrees of freedom proposed or discussed.12-Axis CNC Machining. 12-axis CNC machines are advanced pieces of equipment that stands at the pinnacle of performance and capability in CNC technology. 12-axis machines typically contain two heads, each capable of moving along six different axes: X, Y, Z, A, B, and C. 12-Axis CNC Machining. If 9-axis CNC machining is the whole package, then its 12-axis counterpart is an absolute beast! The 12-axis CNC machines typically contain two heads that allow movement along the X, Y, Z, A, B, and C-axes. This configuration doubles productivity and accuracy while cutting down manufacturing time by half!

mill xyz axis

12-axis CNC. The 12-axis CNC machine is at the top of the performance and capability list for CNC machine. The design of the machine features 2 heads that facilitate movement along axes X, Y, Z, A, B and C planes. 12-axis CNC machines are designed for the most demanding operations that have an array of complexities in their design.Verify the power requirement before running power for your machine. This rotary fits this particular machine, but may require alternative fixturing for proper positioning, such as a sub-plate or alternate T-slot. Need help finding the right machine? Let us help you find the right one for your shop. Need More Information?

To grasp the significance of a 12-axis CNC machine, it is essential to understand the fundamentals of CNC machining. We will explore how a CNC machine works, breaking down its components and functions, before diving into the specifics of the 12-axis variant.From 3-axis to 12-axis CNC milling: Learn how different axes impact production capabilities and choose the right machine for your project.

12-Axis CNC Machining. If 9-axis CNC machining is the whole package, then its 12-axis counterpart is an absolute beast!

cnc axis explained

frc electrical box

free standing home stainless steel free standing mail box

CNC routers are one popular application for CNC machining platforms. As an advanced type of tooling method, CNC routers operate with CAM software programs, a visual programming tool used to create geometric code .

12-axis cnc machining|mill xyz axis