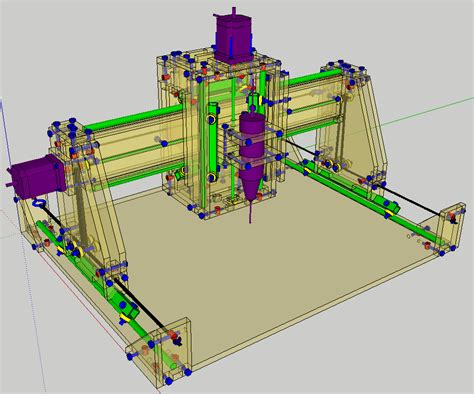

3 axis cnc machine mdf plans and cut list The DIYLILCNC project is a free & open-source set of plans for an inexpensive, fully functional 3-axis CNC mill that can be built by an individual with basic shop skills and tool access. CNC devices are used to fabricate physical objects with . $16.49

0 · 3 axis vacuum machine plans

1 · 3 axis cnc machine design

The movement of the Z coordinate axis is determined by the spindle that transmits the cutting force. The standard coordinate axis parallel to the spindle is the Z coordinate axis, and its positive direction is the direction of increasing .

How to Make a Three Axis CNC Machine (Cheaply and Easily): The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. .The DIYLILCNC project is a set of plans for an inexpensive, fully functional 3-axis CNC mill that can be built by an individual with basic shop skills and tool .The DIYLILCNC project is a free & open-source set of plans for an inexpensive, fully functional 3-axis CNC mill that can be built by an individual with basic shop skills and tool access. CNC devices are used to fabricate physical objects with . The document describes a project to fabricate a 3-axis computer numerical control (CNC) machine carried out by 5 students under the guidance of Prof. Rahul Vaisya. It includes sections on the introduction, fabrication, design, .

3 axis vacuum machine plans

3 axis cnc machine design

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, .Motor Spacer x 3 Z Rail Back x 1 Z Rail Spacer x 1 Z Rail Runner x 1 0.75” MDF (8” x 0.75”) Cut Pattern: CNC-0.75MDF-CutLayout-(8x10).pdf Spacer x 8 0.75” Aluminum Tube Cut Pattern: . The main structures are made of 19mm & 12mm mdf strips that I ordered pre-cut to the correct width. Z and Y axis carriage & some other smaller parts are made from 15mm .

Use the method that is exhibited on the buildyourcnc.com website to drive the nuts into these holes. 3 connect through the the main 4" piece being attached, and two motor mounts. The large center hole is simply to allow space for the couplings and if the bearing is not flush against the main piece. There are six of these pieces onthe machine.

How to Make a Three Axis CNC Machine (Cheaply and Easily): The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. While it would have been nice to purchase an off the shelf unit the issue of price as well as size proved prohibitive.The DIYLILCNC project is a set of plans for an inexpensive, fully functional 3-axis CNC mill that can be built by an individual with basic shop skills and tool access. CNC devices are used to fabricate physical objects with a high degree of precision.The DIYLILCNC project is a free & open-source set of plans for an inexpensive, fully functional 3-axis CNC mill that can be built by an individual with basic shop skills and tool access. CNC devices are used to fabricate physical objects with a high degree of precision.

junction box in north ayrshire

junction box knockout insulation

The document describes a project to fabricate a 3-axis computer numerical control (CNC) machine carried out by 5 students under the guidance of Prof. Rahul Vaisya. It includes sections on the introduction, fabrication, design, and future scope of the project.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials.Motor Spacer x 3 Z Rail Back x 1 Z Rail Spacer x 1 Z Rail Runner x 1 0.75” MDF (8” x 0.75”) Cut Pattern: CNC-0.75MDF-CutLayout-(8x10).pdf Spacer x 8 0.75” Aluminum Tube Cut Pattern: CNC-0.75Alum-CutLayout-(15x10).pdf (Note: Glue Side A to top face of tube and Side B to a side face) Y Axis Bearing Block (Required: 2) Length: 13” The main structures are made of 19mm & 12mm mdf strips that I ordered pre-cut to the correct width. Z and Y axis carriage & some other smaller parts are made from 15mm baltic birch plywood, cut with my first diy machine.

The kit was designed to be hand cut, however if you want to get a CNC machine to cut it, you will have to add the dimension(etc.) Into the code of the CNC machine software to process and cut the MDF. Since we do not provide the files/code.

Video marketing. Power your marketing strategy with perfectly branded videos to drive better ROI. Event marketing. Host virtual events and webinars to increase engagement and generate leads.Use the method that is exhibited on the buildyourcnc.com website to drive the nuts into these holes. 3 connect through the the main 4" piece being attached, and two motor mounts. The large center hole is simply to allow space for the couplings and if the bearing is not flush against the main piece. There are six of these pieces onthe machine.How to Make a Three Axis CNC Machine (Cheaply and Easily): The idea behind this Instructable was to fulfill my desire for a desktop sized CNC machine. While it would have been nice to purchase an off the shelf unit the issue of price as well as size proved prohibitive.

The DIYLILCNC project is a set of plans for an inexpensive, fully functional 3-axis CNC mill that can be built by an individual with basic shop skills and tool access. CNC devices are used to fabricate physical objects with a high degree of precision.The DIYLILCNC project is a free & open-source set of plans for an inexpensive, fully functional 3-axis CNC mill that can be built by an individual with basic shop skills and tool access. CNC devices are used to fabricate physical objects with a high degree of precision. The document describes a project to fabricate a 3-axis computer numerical control (CNC) machine carried out by 5 students under the guidance of Prof. Rahul Vaisya. It includes sections on the introduction, fabrication, design, and future scope of the project.

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials.

Motor Spacer x 3 Z Rail Back x 1 Z Rail Spacer x 1 Z Rail Runner x 1 0.75” MDF (8” x 0.75”) Cut Pattern: CNC-0.75MDF-CutLayout-(8x10).pdf Spacer x 8 0.75” Aluminum Tube Cut Pattern: CNC-0.75Alum-CutLayout-(15x10).pdf (Note: Glue Side A to top face of tube and Side B to a side face) Y Axis Bearing Block (Required: 2) Length: 13”

The main structures are made of 19mm & 12mm mdf strips that I ordered pre-cut to the correct width. Z and Y axis carriage & some other smaller parts are made from 15mm baltic birch plywood, cut with my first diy machine.

The kit was designed to be hand cut, however if you want to get a CNC machine to cut it, you will have to add the dimension(etc.) Into the code of the CNC machine software to process and cut the MDF. Since we do not provide the files/code.

junction box ip66 factories

The cabinets are painted a blackened blue and paired with black marble tops. In contrast, the walls are painted white and accented with stainless steel appliances and light wood open-shelving. Overall, the dark, moody cabinets and use of mixed materials give this kitchen an elevated and lived-in feel.

3 axis cnc machine mdf plans and cut list|3 axis cnc machine design