18 ga sheet metal tolerance Fabrication sheet metal tolerance of 18 gauge. Industrial quality standard for 18 gauge sheets. 18 gauge metals grade specifications. TEAM MFG: Precision 18 Gauge Sheet Metal Processing. . RACO Handy Boxes- the ideal utility box for both new and old applications in ceilings or walls. This versatile box is specifically designed for convenience outlets, switch boxes, or small junction boxes, making it a popular choice for exposed work applications.For most people a screen is just a woven mesh on an aluminum enclosure to keep the bugs out, but for others it can be a means of reducing sunlight, .

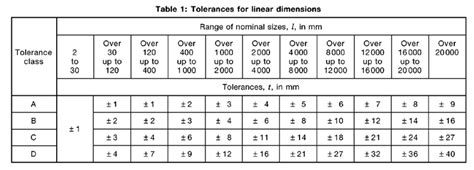

0 · steel sheet mechanical tolerances chart

1 · sheet metal gauge tolerances

2 · sheet metal gauge size chart

3 · metal gauge tolerance chart

4 · astm steel sheet tolerance chart

Discover the different techniques and materials used in automotive sheet metal fabrication, including stamping, deep drawing, laser cutting, welding, and bending. Learn about the .

steel sheet mechanical tolerances chart

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the .

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .Reference Sheet Metal and Wire Gauge Size Data and Table for various . The following charts give typical ASTM and ANSI steel sheet mechanical tolerance .

stainless steel cuff bracelet pink box

sheet metal gauge tolerances

Fabrication sheet metal tolerance of 18 gauge. Industrial quality standard for 18 gauge sheets. 18 gauge metals grade specifications. TEAM MFG: Precision 18 Gauge Sheet Metal Processing. .

Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive. Reference Sheet Metal and Wire Gauge Size Data and Table for various engineering .Browse Cold Rolled Steel Tolerances over/under specifications to find the right size and material for your next project at OnlineMetals.com.For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” .

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.

The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.Fabrication sheet metal tolerance of 18 gauge. Industrial quality standard for 18 gauge sheets. 18 gauge metals grade specifications. TEAM MFG: Precision 18 Gauge Sheet Metal Processing. State-of-the-art CNC machinery for exact tolerance control. 0.0478" thickness with ±0.002" precision. Premium surface finish for immediate use. Fast .Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.

Reference Sheet Metal and Wire Gauge Size Data and Table for various engineering materialBrowse Cold Rolled Steel Tolerances over/under specifications to find the right size and material for your next project at OnlineMetals.com.For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” through 72”.

stainless steel enclosure 1 4 inch

Sheet Metal Tolerances. Because sheets are rolled to the desired thickness there is almost always some crowning of the rollers, resulting in a thinner sheet on the edges compared to the center.

Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The looser tolerances achieved by the sheet metal method are a product of the highly variable processes used to achieve a geometry.

Sheet metal tolerances are the maximum permissible dimension deviation range during sheet metal processing. This concept is vital because it directly affects the quality and performance of the product. Ensuring that every product falls within this tolerance range is essential in our work.

Sheet Metal Guage Tolerances. During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.The following charts give typical ASTM and ANSI steel sheet mechanical tolerance ranges. Carbon Steel Sheets. Galvanized Steel Sheets.Fabrication sheet metal tolerance of 18 gauge. Industrial quality standard for 18 gauge sheets. 18 gauge metals grade specifications. TEAM MFG: Precision 18 Gauge Sheet Metal Processing. State-of-the-art CNC machinery for exact tolerance control. 0.0478" thickness with ±0.002" precision. Premium surface finish for immediate use. Fast .Hot rolled P&O gages 4 through 18 - tolerances shown for widths over 40" to 48" inclusive. All other gages over 15" to 72" inclusive.

Reference Sheet Metal and Wire Gauge Size Data and Table for various engineering materialBrowse Cold Rolled Steel Tolerances over/under specifications to find the right size and material for your next project at OnlineMetals.com.

For cold rolled gauges 4 – 10, tolerances shown are for widths over 48” through 72”. Tolerances for HR and P&O gauges 4 – 18 are for widths over 40” through 48”; all other gauges, over 15” through 72”.Sheet Metal Tolerances. Because sheets are rolled to the desired thickness there is almost always some crowning of the rollers, resulting in a thinner sheet on the edges compared to the center. Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The looser tolerances achieved by the sheet metal method are a product of the highly variable processes used to achieve a geometry.

sheet metal gauge size chart

What Is the Best Way to Cut Sheet Metal? If you are cutting either straight lines or curves, you don’t have power tools, and you don’t have much sheet metal to cut, your best option is to use a pair of tin snips.

18 ga sheet metal tolerance|astm steel sheet tolerance chart