sheet metal assembly techniques The sheet metal assembly process involves several key steps: preparing the metal sheets, aligning them, and then joining them using various methods. Each step must be executed carefully to meet the desired specifications and quality . Our IP69-rated electrical enclosures exceed NEMA 4 and 4x requirements and .

0 · types of sheet metal joints

1 · sheet metal manufacturing process

2 · sheet metal fastening methods

3 · sheet metal fastening

4 · sheet metal fabricator

5 · sheet metal fabrication processes

6 · how to join sheet metal

7 · how to fabricate metal

Millwright, pipe, and industrial fabrication, delivered by expert industrial contractors and craftsmen, on time and on budget. We have the expertise to keep production running, from troubleshooting, tear down and repair, to installation, fabrication and alignment.

types of sheet metal joints

1. Selection of Assembly Reference. Conventionally, support is also called assembly reference, abbreviated as reference. It solves the problem of where to assemble . There are several methods and techniques for joining sheet metal, each with its unique advantages and limitations. Some common methods . This article explores the importance of a streamlined process in sheet metal assembly, the pillars of streamlining, and the tools and technologies for streamlining sheet metal assemblies.Real-life examples of successful sheet metal assembly projects can provide valuable insights and inspiration for craftsmen. By showcasing challenging assembly situations and the lessons learned from them, case studies offer a .

The sheet metal assembly process involves several key steps: preparing the metal sheets, aligning them, and then joining them using various methods. Each step must be executed carefully to meet the desired specifications and quality . Gathering Essential Tools. To get started with sheet metal fabrication, you'll need a few essential tools. A metal shear or snips are necessary for cutting, while a brake or .Sheet metal assembly techniques remains a versatile for joining sheet metal components in various industries. So, let's explore.

Looking for the best sheet metal joining techniques? Our comprehensive guide provides all the information you need to choose the right technique for your project. Check it out now! Close; Articles. . Quick . Top 11 Sheet Metal Assembly Techniques For Metalwork. Dedasun Technology(Shenzhen)Co.,Ltd. Email : [email protected] . Tel : +8615889615375. Home. About Us. Products. . Well, this guide explores some of the most common top 11 sheet metal assembly options to choose from. I know probably you are looking for the best way to .Introduction . Sheet metal assembly is a crucial skill for any craftsman working with metal. The ability to create seamless and strong joints in sheet metal can make or break a project. In this blog post, we will explore the top techniques . Sheet Metal Parts 14. Sheet Metal Forming Tools 15. Sheet Metal Conversions 16. Working with Sheet Metal STEP Files 17. Advanced Weldments 18. Creating a Core & Cavity 19. Non Planar Parting Lines 20. Top-Down Assembly - Part 1 21. Top-Down Assembly – Part 2 22. External References & Repair Errors 23.

Sheet metal welders work in various world industries, including aerospace, automotive, marine, electronics, assembly plants, etc. Like other manufacturing processes, making high-quality welds requires skill and expertise. Different Techniques of Welding Sheet Metal. Are you concerned with how to sheet metal welding? Sheet Metal Cutting Techniques Shearing. Shearing is one of the most basic and widely used sheet metal cutting techniques. A shear is basically a pair of blades used to make straight cuts into sheet metal, and is most suitable for thin- to medium-gauge sheet metal. Sawing. Sawing is another traditional metal cutting technique.Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Click Options (Standard toolbar).; On the System Options tab, click Drawings > Display Style.; Under Tangent edges, select Visible, and click OK.; Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, .

This article covers various types of sheet metal joining techniques, their advantages, disadvantages, and applications. Factors affecting the selection of type of Sheet Metal Joint. . Self tapping screws are a low-cost solution for the one-time assembly of sheet metal parts. They require a pilot or extruded hole in one of the sheet metal parts. Sheet metal notching errors lead to material waste, project delays, and quality issues that harm the bottom line. With proper notching techniques, manufacturers reduce scrap rates by 35% and speed up assembly time by 40%. Sheet metal notching creates precise cuts and openings in metal sheets, enabling parts to fit together seamlessly during .

Learn assembly techniques that work well with sheet metal parts. Skip to main content . The tools we use for assembling sheet metal parts are the same tools we use for any type of SolidWorks .

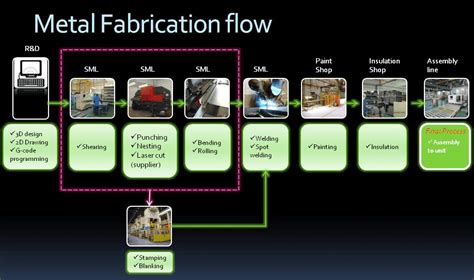

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. Sheet metal is made from various materials, including steel, aluminum, zinc, and copper.

Complex sheet metal fabrication projects demand mastery of the full range of sheet metal fabrication techniques and technologies, including expert CAD capabilities. Complex projects often require additional fabrication capabilities in solid metal, synthetic or organic material manufacturing and assembly to create a high quality finished product that satisfies the design .

Assembly without Fasteners Fasteners cost money. Fasteners contribute to the increase of Bill of Materials (BOM) besides inventory costs. It is possible in sheet metal product design to assemble parts without fasteners. (Image source) (Image source) Assembly with Inbuilt Hooks (Image Courtesy: Pelican Shelving) One wonderful property of sheet metal is its rigidity yet at the . Mastering sheet metal fabrication requires not only the right tools and materials but also a variety of techniques to achieve precision and efficiency. Exploring different methods for cutting, bending, and joining will allow you to choose .Sheet metal assembly techniques remains a versatile for joining sheet metal components in various industries. So, let's explore. Skip to content +86-18969433502; [email protected]; Contact Us. Search. Search.Discover Taiwa's comprehensive sheet metal assembly services, backed by 20 years of expertise. Our holistic approach to sheet metal fabrication ensures precise assembly from start to finish. We offer welding, crimping, riveting, stud .

This sheet metal assembly technique can join sheet metal with other materials such as wood and plastic. Pros: Simple, straightforward process . In addition, sheet metal manufacturers can use sheet metal fabrication techniques to .

sheet metal manufacturing process

What is sheet metal assembly? Once we have created your components using a variety of sheet metal fabrication techniques, we come to the final stage – assembly. So, what’s involved in the assembly process? During assembly, we take a range of components and join them together to form the desired final product. To achieve this, we may use a single technique or a variety of . A sheet metal assembly is usually made by putting two or more sheets of metal together that are joined by some spot welds, fasteners or seam welds. . As it was mentioned in Section 1.1, in conventional selective assembly techniques, the parts are divided to some groups based on their measured dimension. However, it is not possible to apply .

This comprehensive guide will explore Sheet Metal Assembly Techniques and Tips, as well as a Guide to Sheet Metal Repair and Maintenance. Grasping the Sheet Metal Fabrication Sheet metal working is the practice of using different processes such as cutting, bending, and assembling of metal, particularly steel sheets to produce certain forms and . A sheet metal assembly is usually made by putting two or more sheets of metal together that are joined by some spot welds, . in conventional selective assembly techniques, .SOLIDWORKS 2024 Advanced Techniques picks up where SOLIDWORKS 2024 Intermediate Skills leaves off. Its aim is to take you from an intermediate user with a basic understanding of SOLIDWORKS and modeling techniques to an advanced user capable of creating complex models and able to use the advanced tools provided by SOLIDWORKS. The text covers parts, .Join Gabriel Corbett for an in-depth discussion in this video, Basic assembly techniques, part of SOLIDWORKS 2013-2017: Sheet Metal Design.

Sheet metal riveting provides a lasting and secure way to fasten components together. This method utilizes an automatic pneumatic hammer to insert rivets, which are bolt-like fasteners, through sheet metal in a way that deforms and permanently fastens components. The result is a strong connection, comparable to welding but at a lower cost.Sheet Metal: Apply basic sheet metal functionality, such as flanges and bends. Create a sheet metal drawing. 45 minutes: Sheet Metal: Forming Tools: Use formed parts in the Design Library for more efficient sheet metal part design. 20 minutes: Design Tables: Create variations of the same part by customizing parameters. Low temperature soldering for delicate sheet metal structures. Soldering requires melting a lower temperature metal or alloy that flows into the gap between the sheets being joined, at temperatures up to 450C. For thin sheet materials it reduces the issue of distortion from welding, and can produce a very strong bond.. Soldering is a labor intensive method that .

Overview of manufacturing techniques of sheet metal enclosure; Key tips for your sheet metal enclosure design; 1) Understanding material types used in sheet metal enclosure. . The next step that follows after the final assembly of all components of an enclosure should be coating or finishing. This coating procedure serves the purpose of .

wholesale cnc vertical machine center manufacturers

Shop Boxes, Fittings, and Conduit online at AceHardware.com and get Free Store Pickup at your neighborhood Ace.

sheet metal assembly techniques|sheet metal fastening